Paper separating mechanism and paper separation and focusing mechanism using same

A technology of separation mechanism and aggregation mechanism, which is applied in the direction of pile separation, object separation, thin material processing, etc., and can solve problems such as posture deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

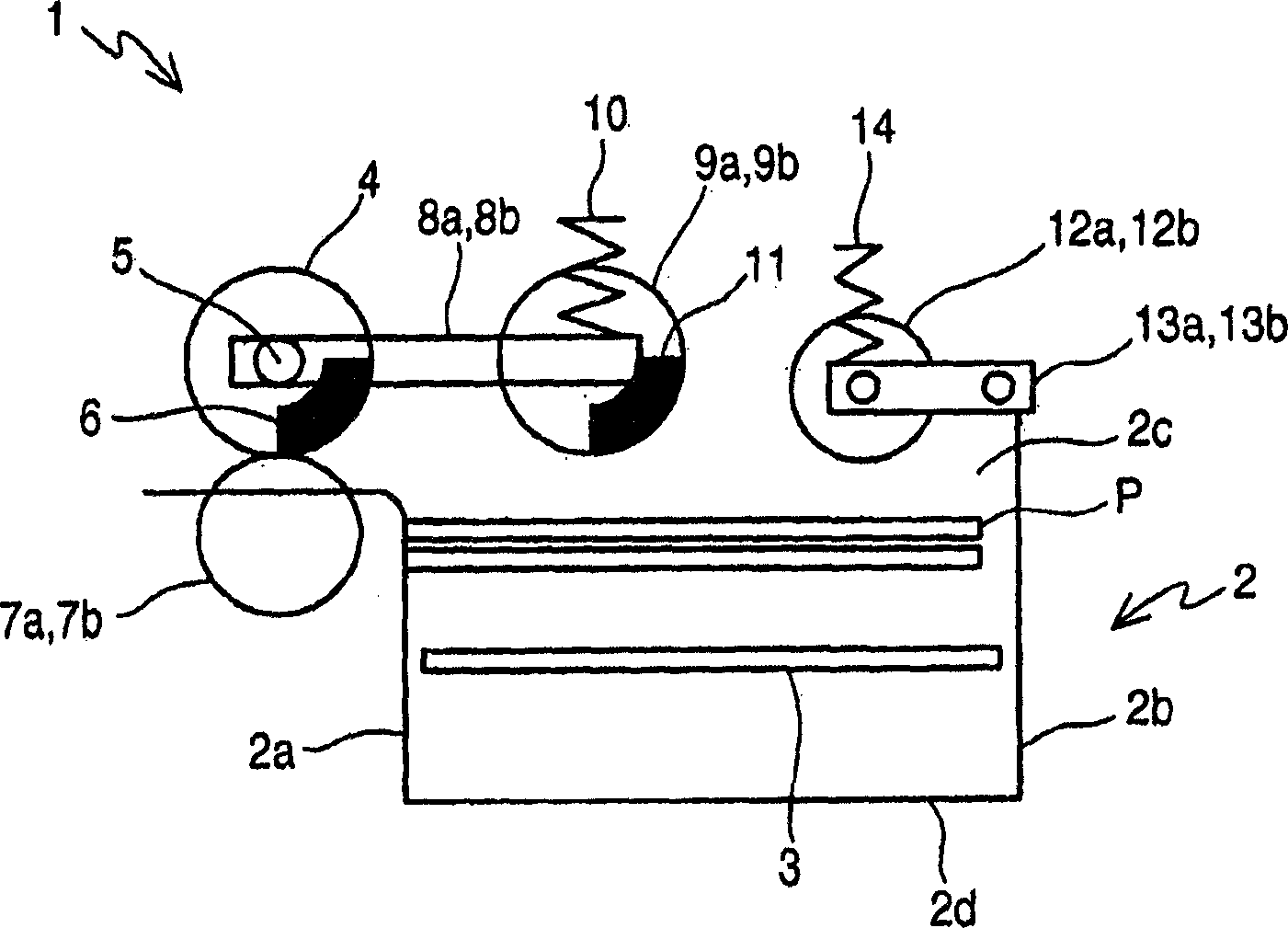

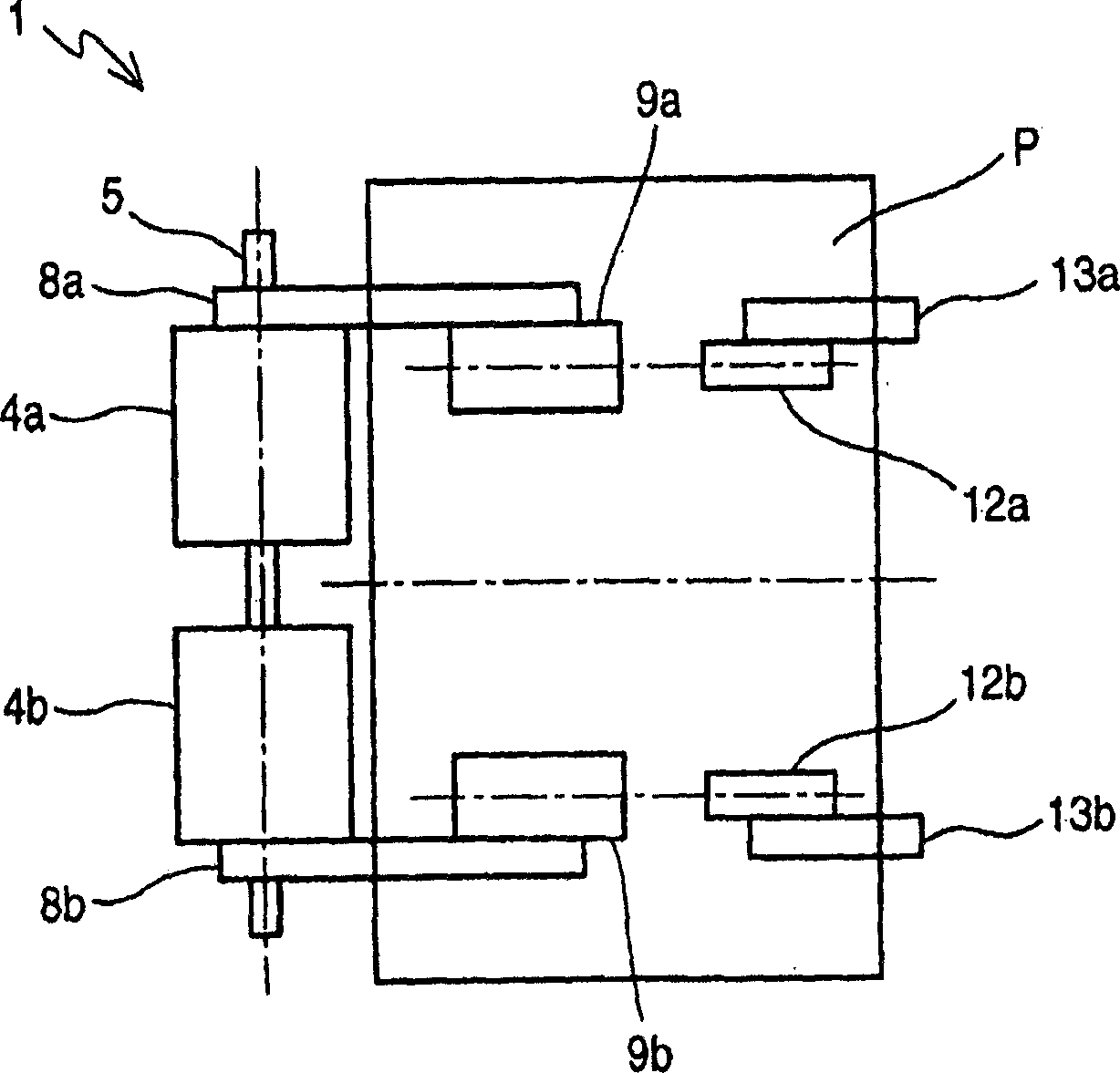

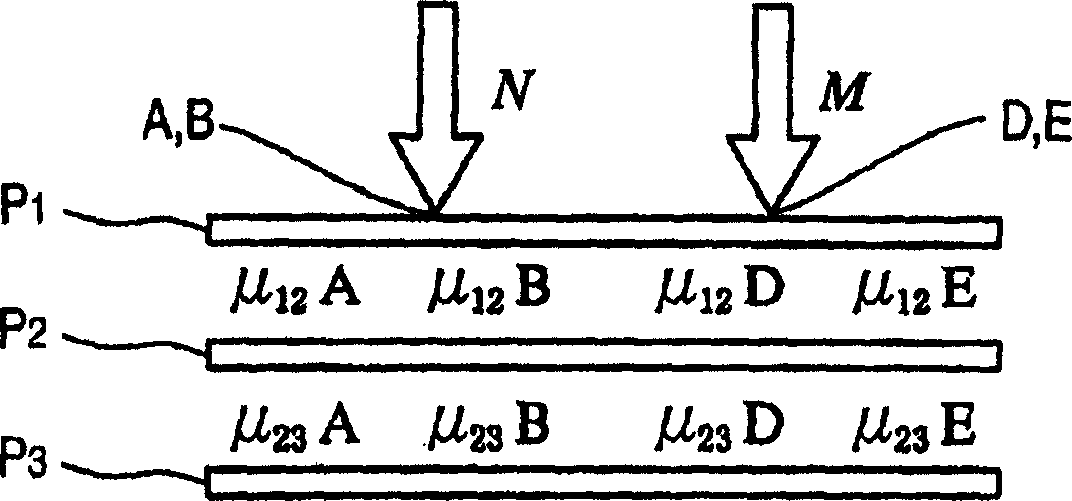

[0039] figure 1 To show a side view of the sheet separation mechanism of Embodiment 1, figure 2 In order to show the top view of the sheet separation mechanism of Embodiment 1, image 3 It is an explanatory diagram showing the force acting on the gathered sheets of Example 1, Figure 4 It is an explanatory diagram showing the force acting on the next sheet of paper when the sheet of Example 1 is fed out.

[0040] exist figure 1 , figure 2 Among them, symbol 1 is the paper separation mechanism.

[0041] Reference numeral 2 is a paper storage section, which is a box body including a front panel 2a, a rear panel 2b provided opposite to the front panel 2a, and a pair of side panels 2c and a bottom panel 2d provided on the sides of the front panel 2a and the rear panel 2b. , has a table 3 that is reciprocally moved away from or close to the bottom plate 2d by a drive mechanism not shown in the figure, and the sheets P are collected on the table 3 .

[0042] figure 1 The st...

Embodiment 2

[0082] Figure 6 In order to show the top view of the sheet separation and gathering mechanism of Embodiment 2, Figure 7 It is a side view showing the sheet separation and gathering mechanism of the second embodiment.

[0083] The same reference numerals are assigned to the same parts as those in the above-mentioned first embodiment, and description thereof will be omitted.

[0084] exist Figure 6 , Figure 7 Among them, symbol 15 is a paper separation and gathering mechanism.

[0085] Reference numeral 20 denotes a paper pressing portion, which is formed by attaching one end of pressing roller arms 13a, 13b to a shaft 21 capable of reciprocating movement in the same direction as table 3 by a drive mechanism not shown in the figure.

[0086] In this example, if Figure 6 As shown, pickup arms 8a and 8b are provided on both sides of the supply roller 4a, and a pickup arm 8c with a pickup roller 9c and a pickup arm 8d with a pickup roller 9d are newly installed on both si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com