Real-time braking distributing device and method for motor vehicle

A distribution device and braking force technology, applied in the direction of brakes, etc., can solve the problems of not being able to adjust the braking force of the front and rear axles in real time, not being able to make full use of the adhesion of the front wheels, and the braking distance of motor vehicles becoming longer, so as to achieve a method of controlling distribution Simplicity, prevention of tail drift and sideways movement, and short braking distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

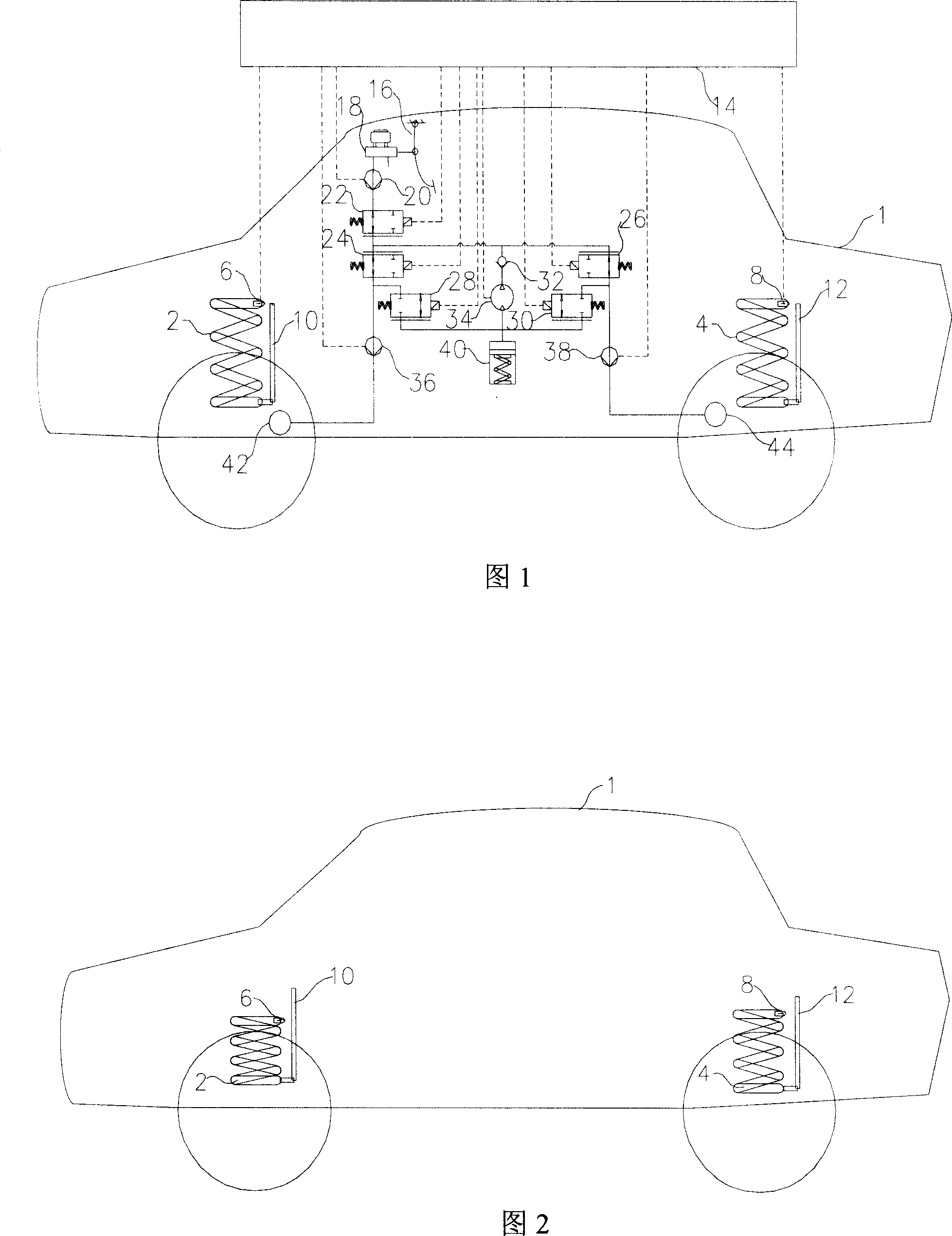

[0038] The structure of the specific embodiment of the device of the present invention is shown in FIG. 1 . Including motor vehicle body 1, front suspension spring 2, detection head 6 of front suspension displacement sensor, fixed part 10 of front suspension displacement sensor, rear suspension spring 4, detection head 8 of rear suspension displacement sensor, rear suspension Fixed part 12 of frame displacement sensor, electronic control unit 14, brake pedal 16, brake master cylinder 18, brake master cylinder pressure sensor 20, normally open valve 22, front wheel brake force control valve 24, front brake wheel cylinder drain Pressure valve 28, front brake wheel cylinder pressure sensor 36, front brake wheel cylinder 42, rear wheel brake force control valve 26, rear brake wheel cylinder pressure relief valve 30, rear brake wheel cylinder pressure sensor 38, rear brake wheel cylinder 44, single To valve 32, hydraulic pump 34 and reservoir 40.

[0039] The upper end of front su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com