Glass hole drilling tool

A technology for drilling tools and glass, applied in manufacturing tools, work accessories, stone processing equipment, etc., can solve problems such as misalignment, broken glass residue, and troublesome cleaning, and achieve the effect of preventing side shifting and avoiding drill burning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The following is a further description of the technical solution of the present invention in conjunction with the accompanying drawings and embodiments.

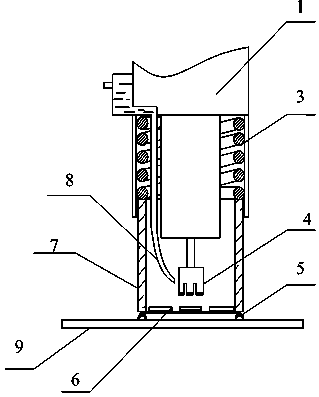

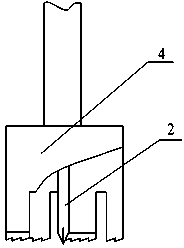

[0014] according to figure 1 and figure 2 As shown, the glass drilling tool includes a hand-held electric drill 1, a hollow thin-walled drill 4 and a positioning cover 7. The drill body of the hand-held electric drill 1 is integrally formed as a sliding cavity, and the positioning cover 7 is embedded in the sliding cavity. In order to make the positioning cover 7 The restoring force can be obtained. A spring 3 is set in the sliding cavity. The suction cup 5 is fixedly connected to the bottom of the positioning cover 7. The suction cup 5 is a C-shaped rubber ring groove. The hollow thin-walled drill 4 is installed on the central axis of the hand-held electric drill 1 rotation. , the working part of the hollow thin-walled drill 4 is a multi-tooth drill surface with gaps, a bar-shaped drill 2 is fixed at the center of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com