Floating roller for a packaging machine and method for threading a sheet web thereon

A floating roller and machine technology, applied in packaging machines, multiple packages, special packaging objects, etc., can solve the problem of high cost and achieve the effect of uniform load distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

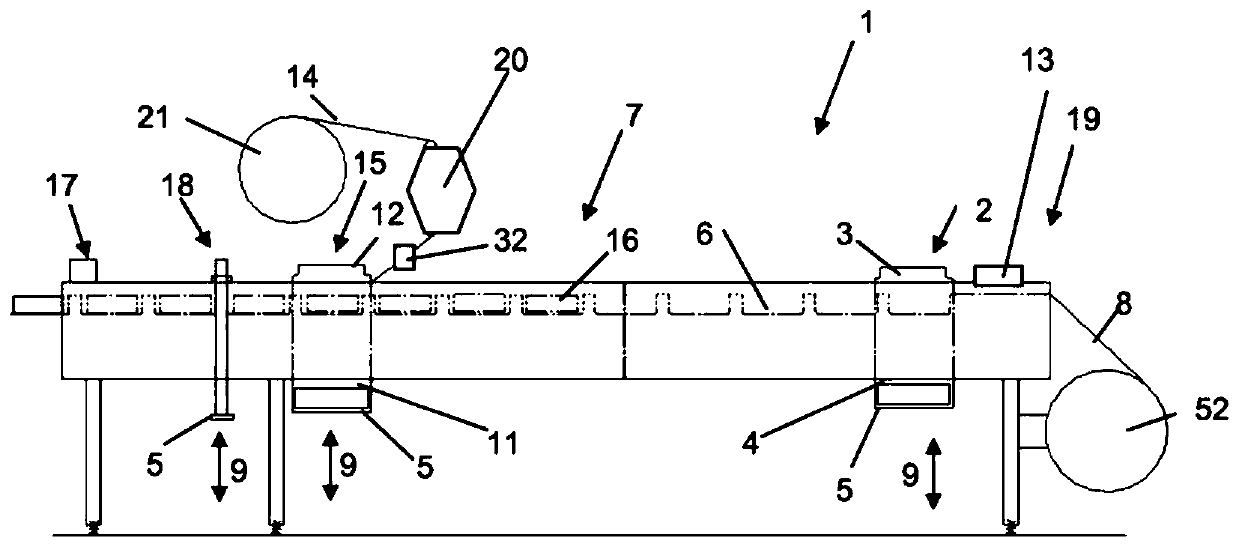

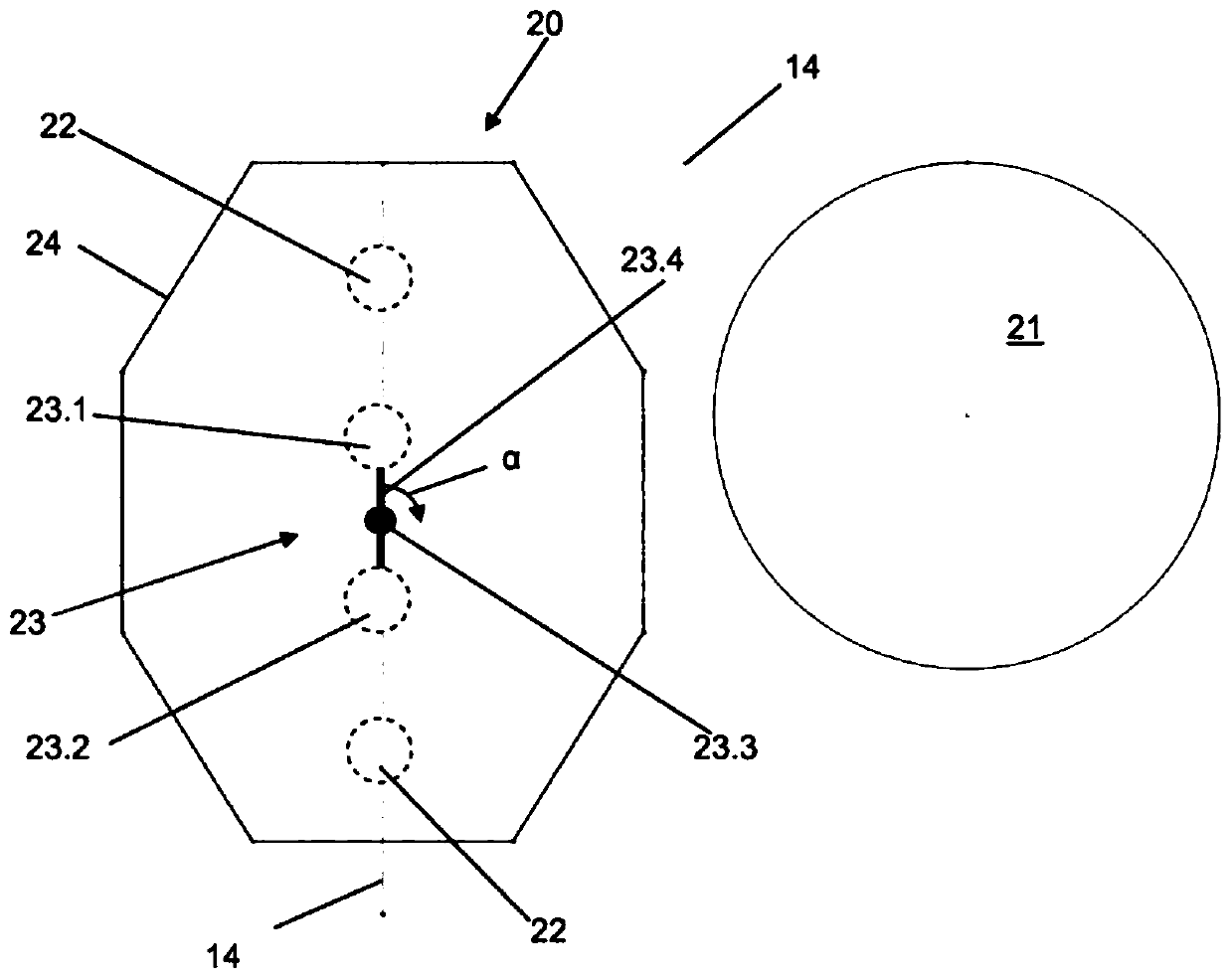

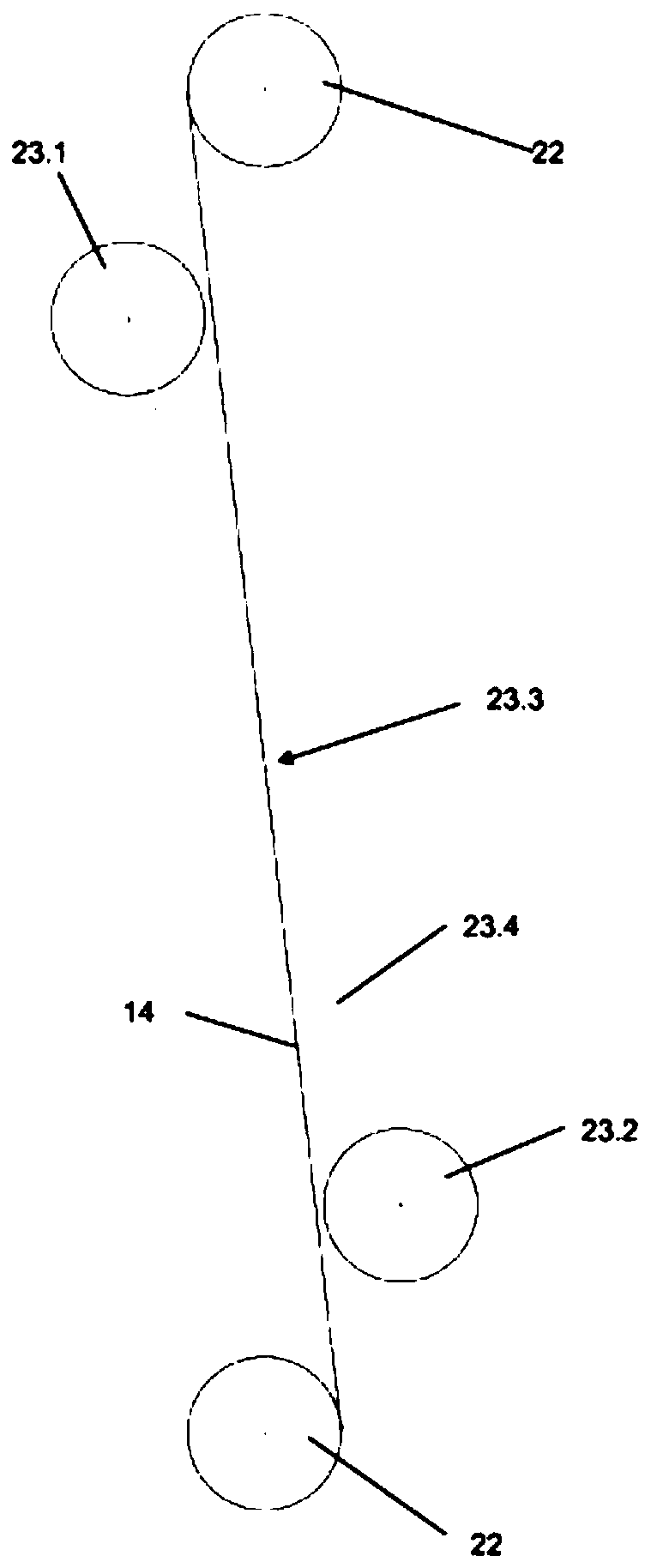

[0040] figure 1 A packaging machine 1 according to the invention is shown having a deep drawing station (forming station) 2 , a filling station 7 and a sealing station 15 . The lower sheet web 8 , here the plastic sheet web 8 , is withdrawn from the backup rollers 52 and transported along the packaging machine according to the invention from right to left in a timed manner. At one clock, the lower sheet web 8 continues to be transported for a format length. For this purpose, the packaging machine has two transport devices (not shown), in this case two endless chains each, which are arranged to the right and to the left of the lower sheet web 8 . Not only at the start and end of the packaging machine, respectively, at least one gear wheel is provided for each chain, around which the corresponding chain is deflected. At least one of these gears is driven. The gears in the entry area and / or in the exit area can preferably be connected to each other by rigid shafts. Each tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com