Tie-bar-less two-plate blow molding machine electric mold opening and closing device with quick mold adjustment function and method for realizing mold opening and closing

A mold opening and closing technology without tie rods, which is used in the field of polymer blow molding machinery opening and closing molds, can solve problems such as large and complex structures, and achieve the effects of reducing manufacturing costs, reasonable operating procedures, and reducing debugging time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

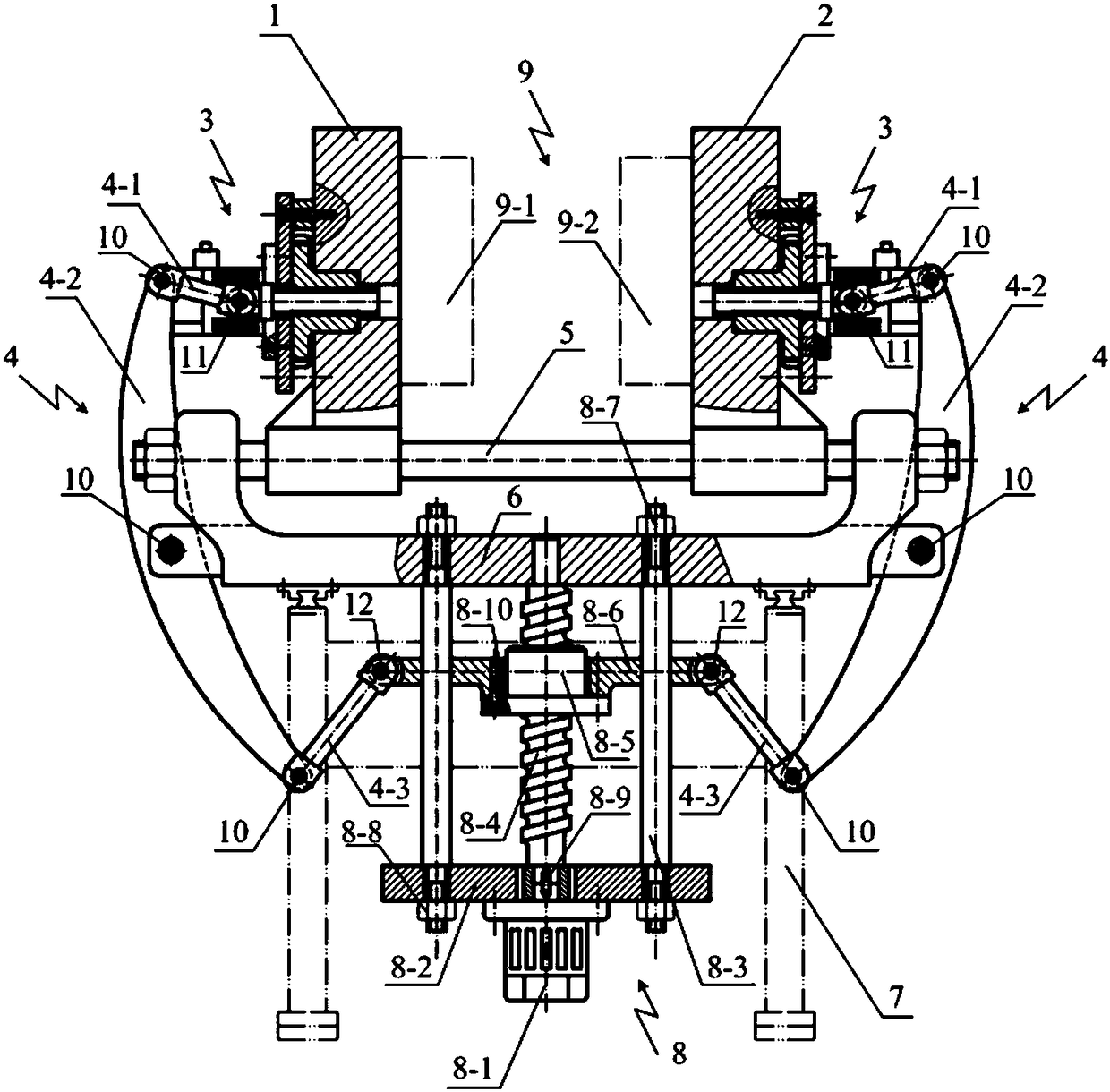

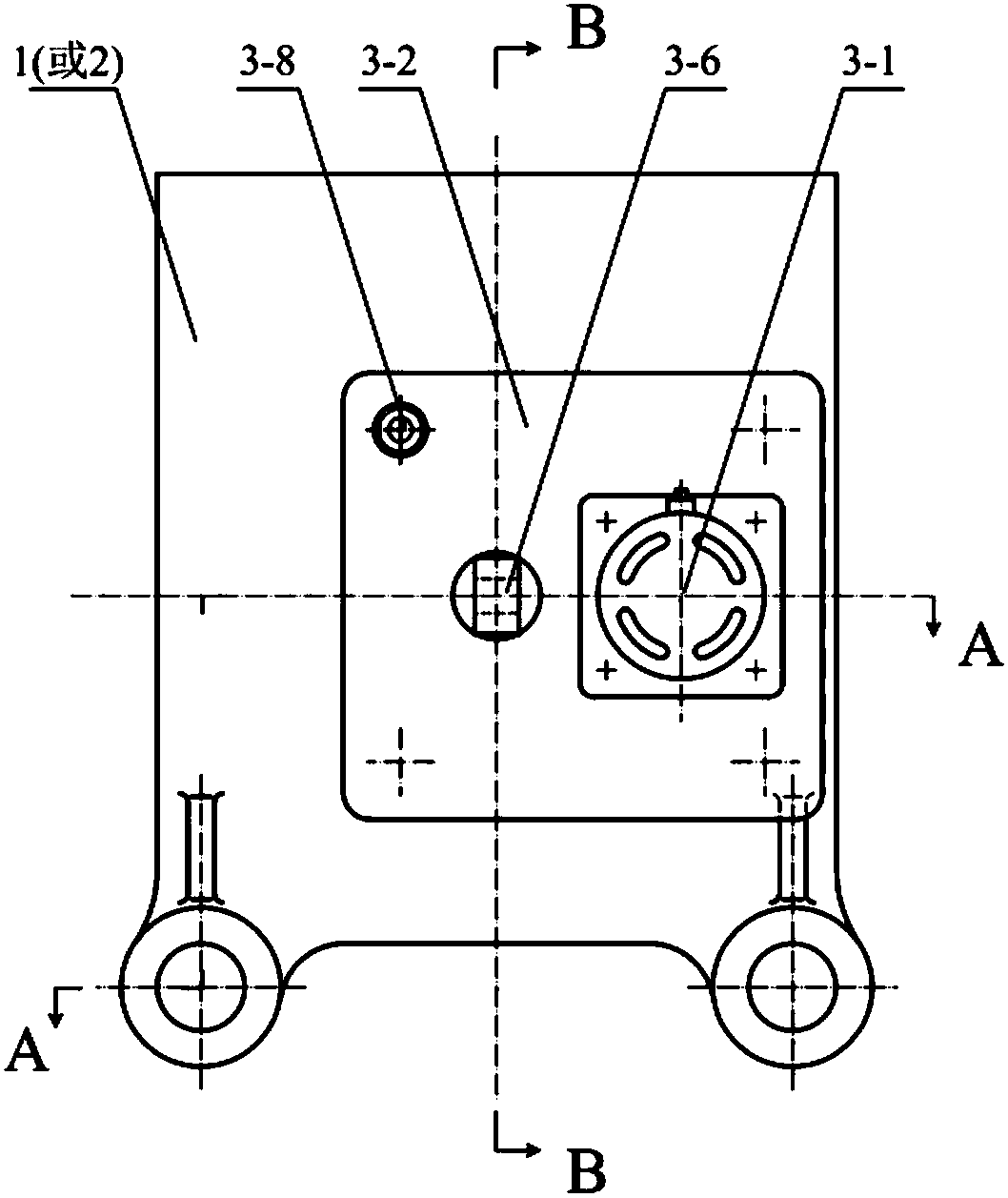

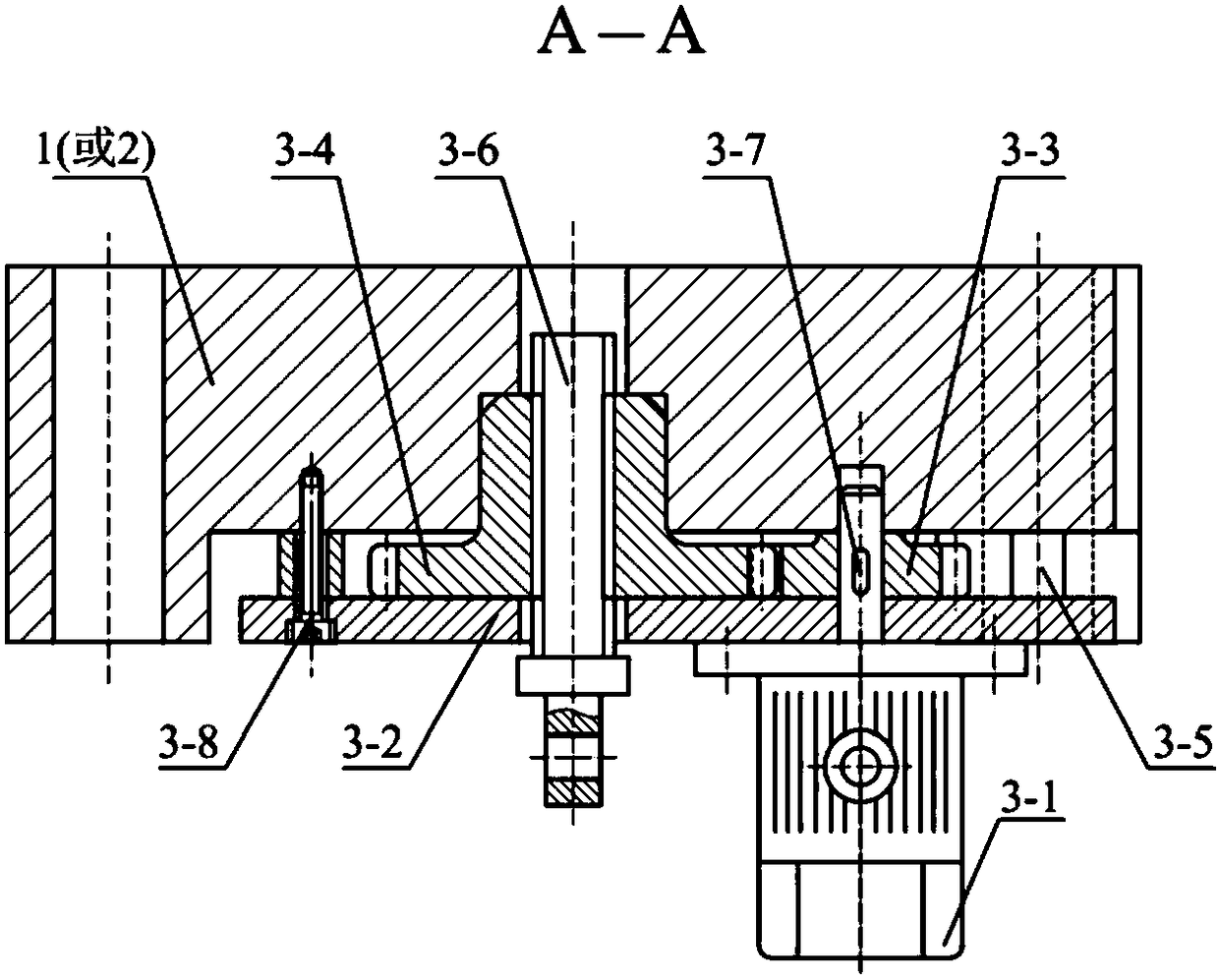

[0031] figure 1It shows a schematic structural view of the electric mold opening and closing device of the two-platen blow molding machine without tie rods and has the function of rapid mold adjustment according to the present invention. It can be seen from the figure that the electric mold opening and closing device of the two-plate blow molding machine without tie rods provided by the present invention with the function of rapid mold adjustment includes cavity half-mold mounting plate 1, core half-mold mounting plate 2, and mold adjustment assembly 3 , Link mechanism 4, guide element 5, mold clamping frame 6, mold moving frame 7 and electric drive unit 8 for opening and closing molds. The guide element 5 is installed on the top of the mold clamping frame 6; the cavity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com