Evaluation method for adhesion of oil modified asphalt and aggregate

An evaluation method and oil modification technology, applied in analytical materials, material thermal analysis, measuring devices, etc., can solve the problem that the water damage resistance of asphalt mixture is difficult to accurately evaluate, the adhesion lacks a quantitative and accurate evaluation method, The internal structure of asphalt pavement is damaged and other problems, and the evaluation results are accurate and reliable, avoiding the influence of human subjective factors, and the evaluation method is fast.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0049] Specific implementation mode one: combine figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 and Figure 10 Describe this embodiment. In this embodiment, at least two aggregate samples are selected. Each aggregate sample is correspondingly provided with a set of asphalt samples. Each set of asphalt samples includes matrix asphalt samples and various oil-modified asphalt samples. After each aggregate sample and its corresponding group of asphalt samples were boiled, the asphalt peeling index and asphalt peeling rate were calculated, and the adhesion between oil-modified asphalt and aggregate was evaluated according to the calculation results.

[0050] Further, the number of types of aggregate samples is at least two, the purpose is to study the sensitivity of the spalling resistance of oil-modified asphalt to lithology, when the number of types of aggregate samples is two, the two The aggregate samples are prefe...

specific Embodiment approach 2

[0057] Embodiment 2: This embodiment is a further limitation of Embodiment 1. In this embodiment, limestone and basalt with a maximum nominal particle size of 9.5 mm are used as aggregates in the boiling operation. Each aggregate sample and its corresponding group of asphalt samples were boiled for base asphalt samples, and each aggregate sample was boiled for each oil-modified asphalt sample. Same, the operation process is:

[0058] Step 1: Wash the aggregates used and dry them in an oven at 100°C for 11.5 to 12.5 hours;

[0059] Step 2: Weigh 1kg of aggregate and 30g of base asphalt, respectively, and place the weighed 1kg of aggregate and 30g of base asphalt into an oven at 155°C for 3 hours at a constant temperature;

[0060] Step 3: Put 30g of matrix asphalt and 1kg of aggregate heated in step 2 into a mixing pot and stir for 1.5 to 2.5 minutes to form a matrix asphalt mixture specimen;

[0061] Step 4: Put the matrix asphalt mixture specimen that has been stirred in St...

specific Embodiment approach 3

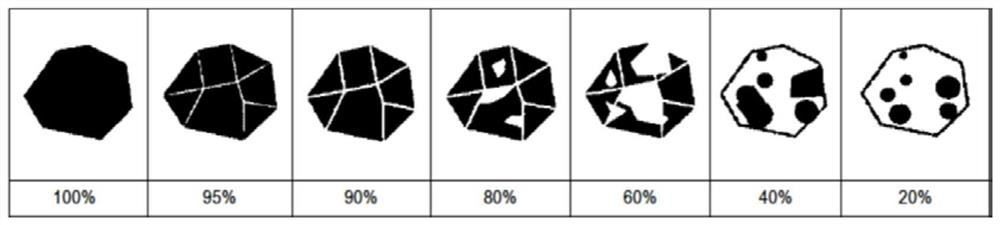

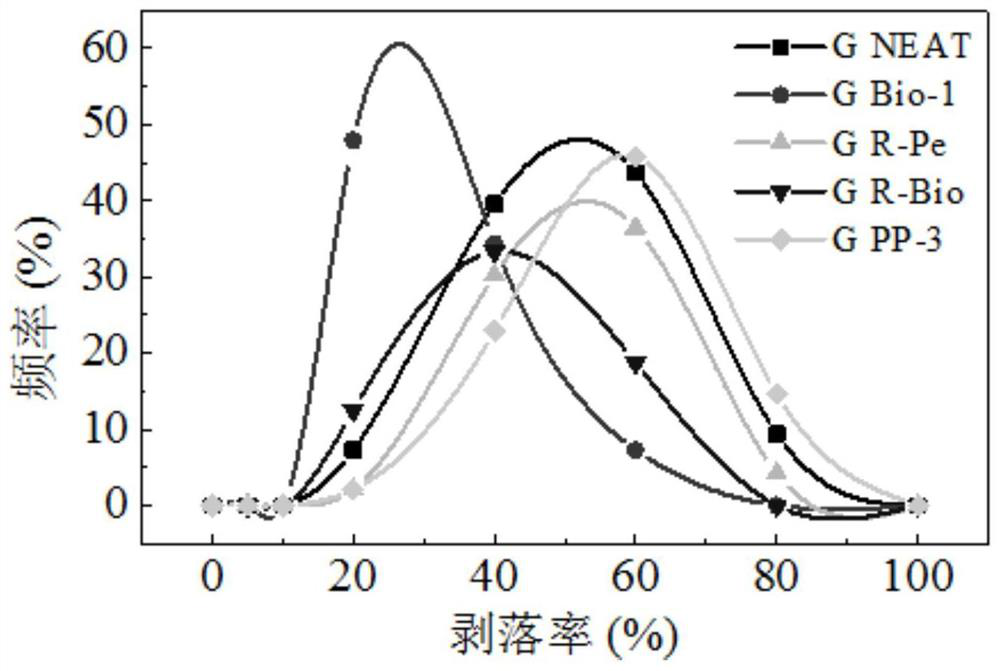

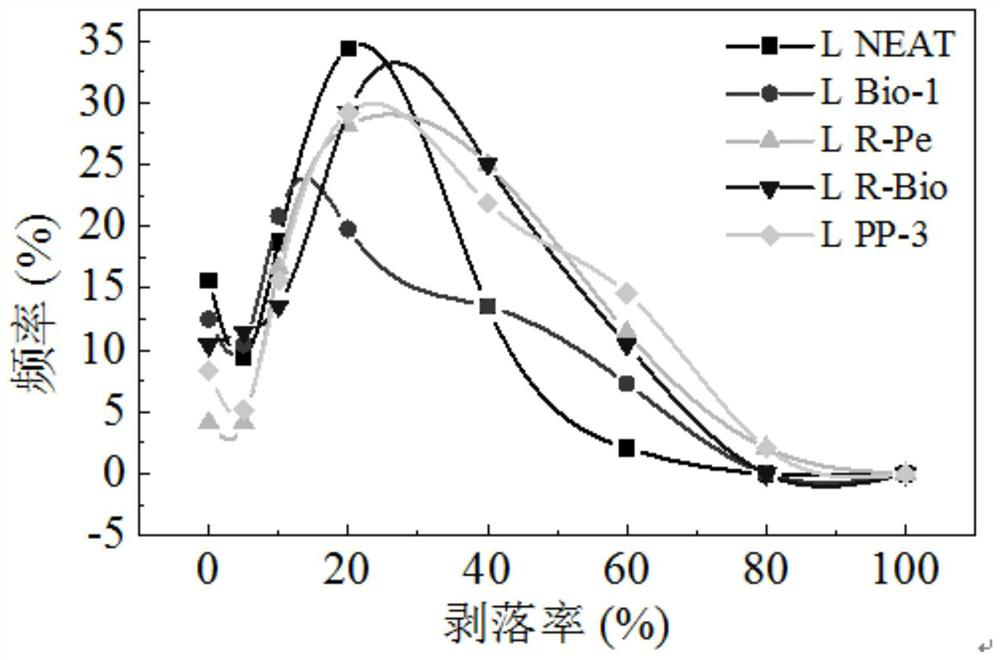

[0068] Embodiment 3: This embodiment is a further limitation of Embodiment 1 or 2. According to UNI EN12697-11 (2012), the asphalt coating ratio of the base asphalt mixture and the asphalt coverage of different oil-modified asphalt mixtures Calculate the occurrence frequency of aggregates under each stripping rate condition, draw the frequency curve, and calculate the asphalt coating rate of the matrix asphalt mixture and the stripping index SI of different oil-modified asphalt mixtures, so as to quantitatively evaluate the matrix The anti-stripping performance of asphalt mixture and different oil-modified asphalt mixtures, the asphalt coverage rate of the base asphalt mixture and the quantitative order of the peeling ability of different oil-modified asphalt mixtures from strong to weak, peeling index The formula for calculating SI is:

[0069]

[0070] In the above formula, N i for the M i Frequency of occurrence of aggregates under spalling rate conditions.

[0071] S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com