Method for improving qualification rate of mineral powder of slag vertical mill

A qualification rate and slag technology, applied in the field of improving the qualification rate of slag vertical grinding ore powder, can solve the problems of unreasonable equipment structure, many impurities in the grinding material, complicated operation process, etc., so as to overcome the unreasonable equipment structure and improve the concentration The effect of powder efficiency and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Preferred embodiments of the present invention are described below, and it should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0023] According to an embodiment of the present invention, a method for improving the pass rate of slag vertical mill ore powder is provided.

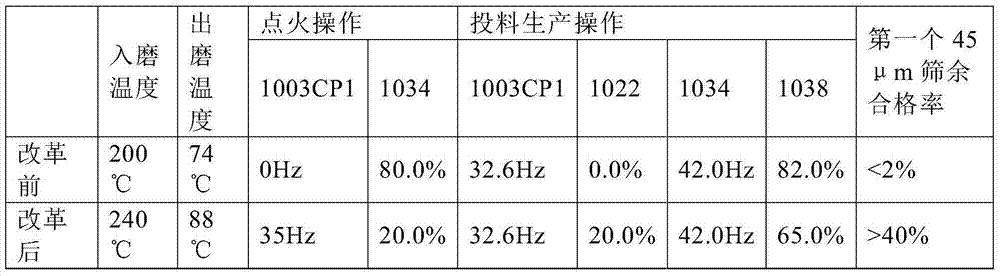

[0024] The technical scheme of the present invention can improve the pass rate of the fineness of the slag vertical mill to more than 80 percent, and the fineness of the ore powder: 45 μm sieve ≦ 1.0 percent.

[0025] The formulation of the technical solution of the present invention is due to the countermeasure plan:

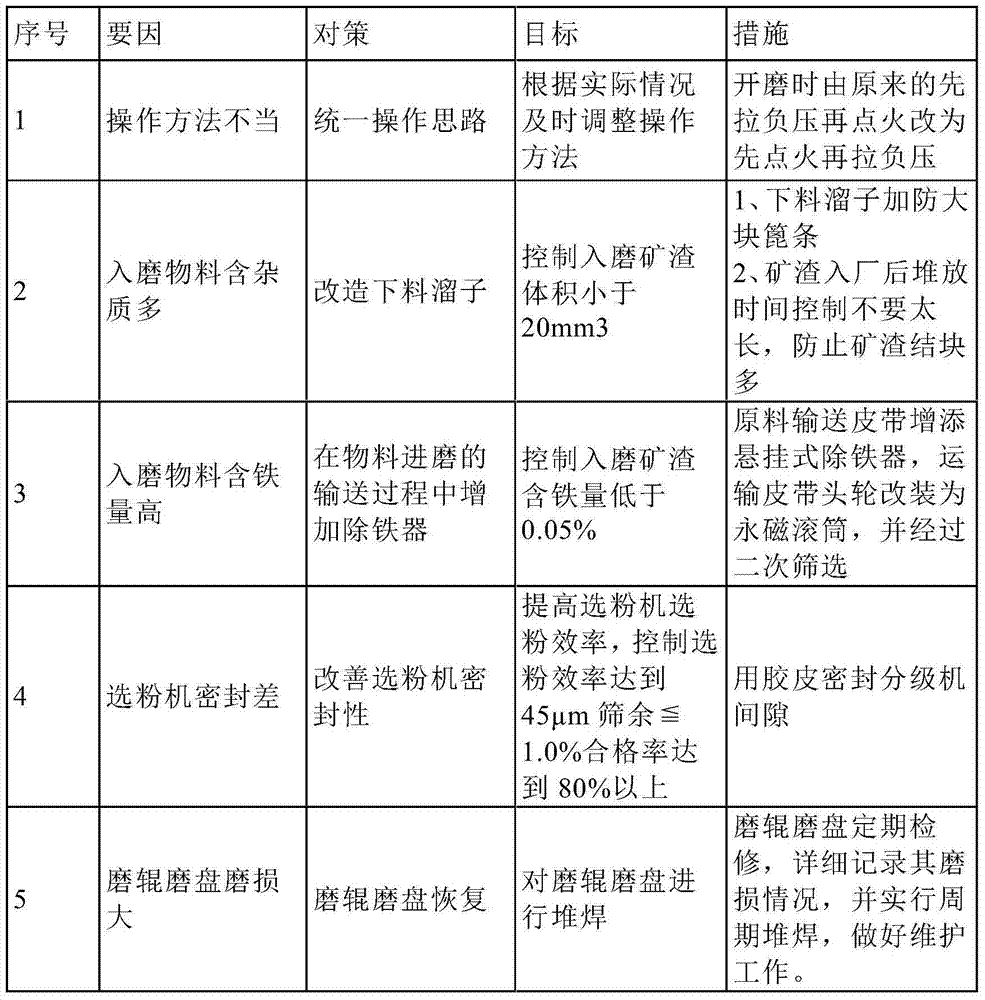

[0026] After confirming the final cause, we found out five main reasons for the low pass rate of slag vertical mill fineness. In order to achieve the goal of slag fineness pass rate of slag vertical mill reaching more than 80%, we formulated the following ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com