Extrusion blow molding machine electric mold opening and closing device and method based on mold electromagnetic attraction

A technology of electromagnetic suction and extrusion blow molding, which is applied in the field of electric mold opening and closing devices of extrusion blow molding machinery, and can solve the problems of demanding machining accuracy of mechanical toggle levers, low mold clamping reliability, and aggravating toggle lever wear. , to achieve the effect of compact structure, shortening size and ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

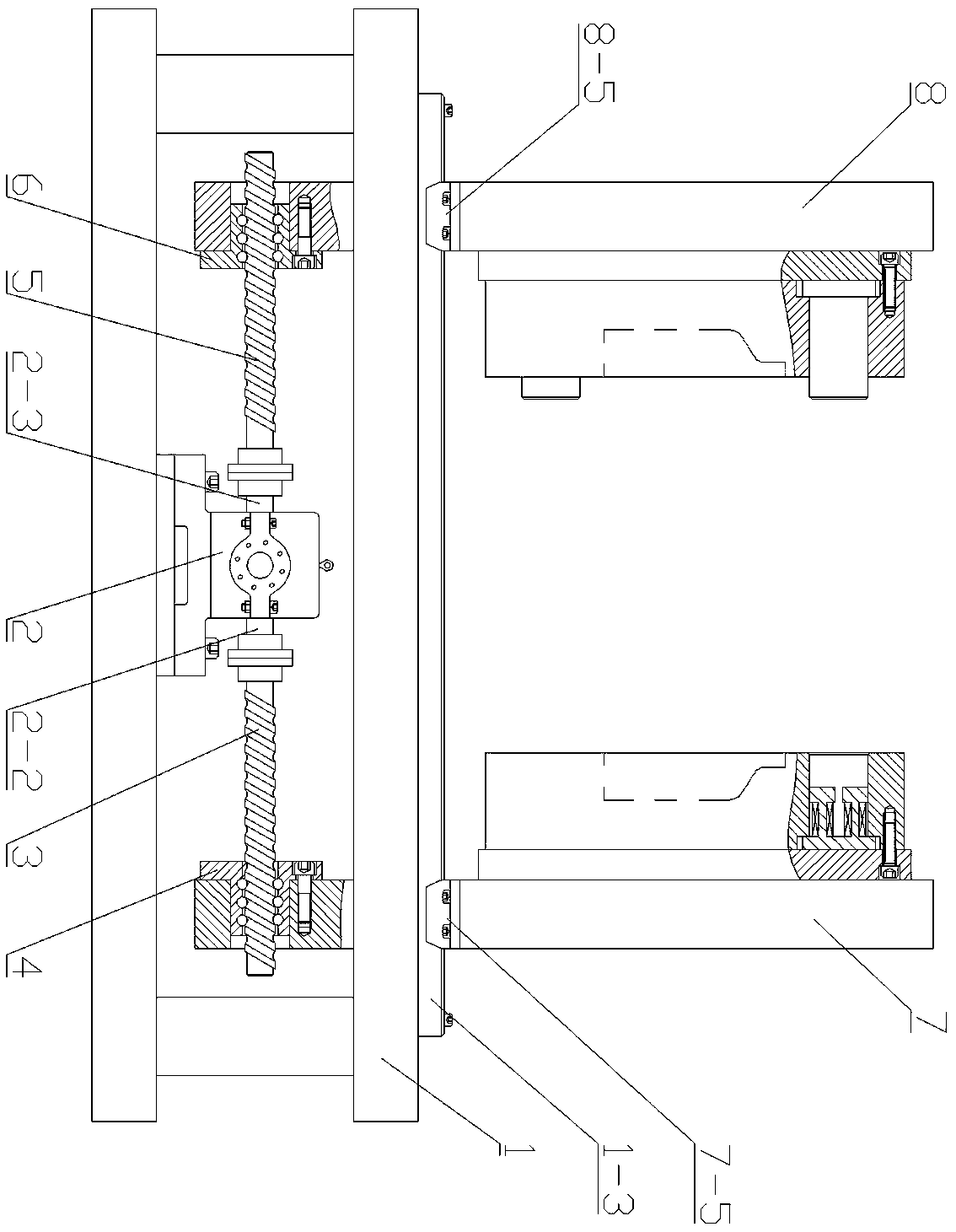

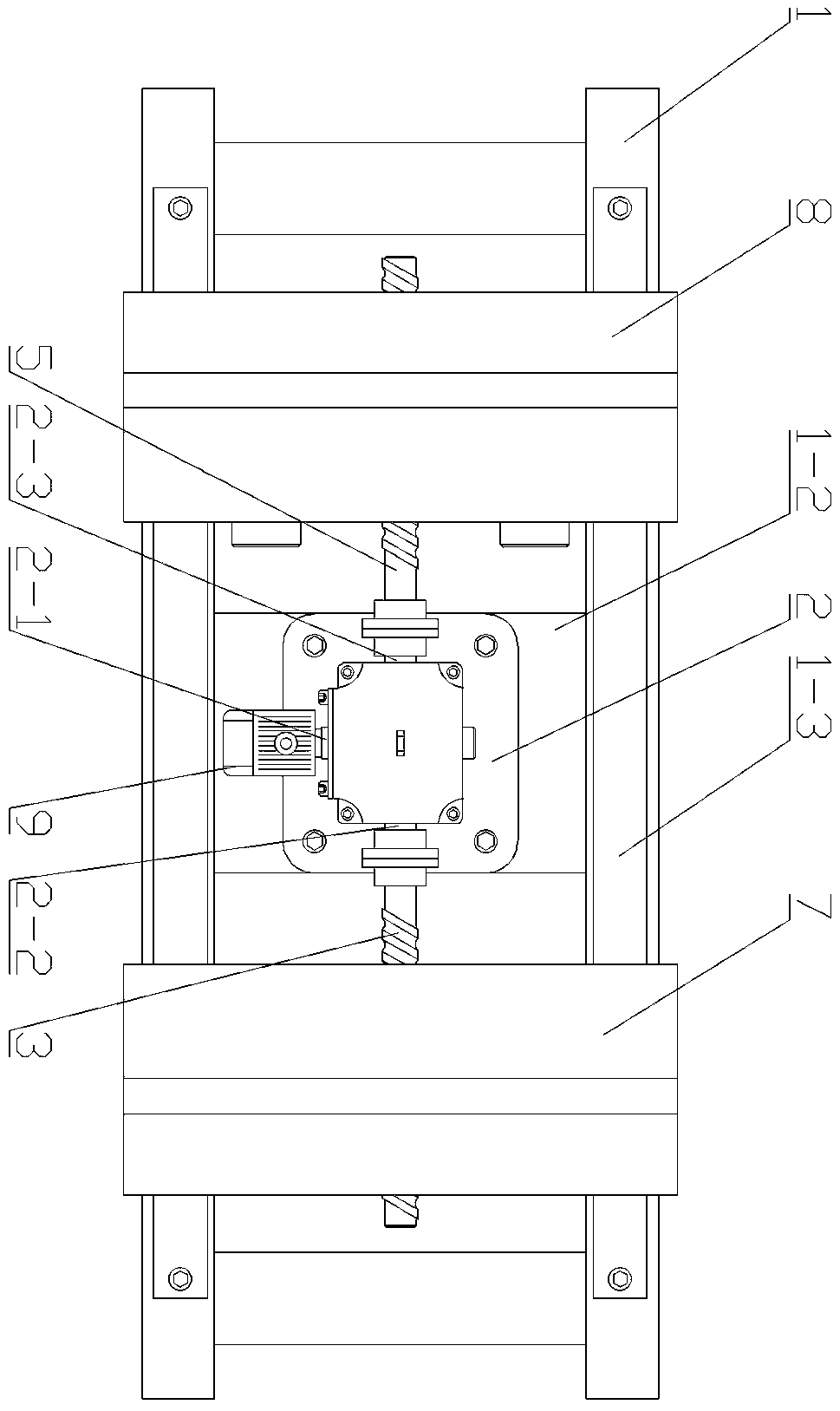

[0040] Embodiment one, such as Figure 1~10 As shown, the extrusion blow molding machine electric mold opening and closing device based on the electromagnetic attraction of the mold includes a frame 1, a bevel gearbox 2, a first ball screw 3, a first screw nut 4, and a second ball screw 5 , the second lead screw nut 6, the cavity half-mold assembly 7, the core half-mold assembly 8 and the servo motor 9.

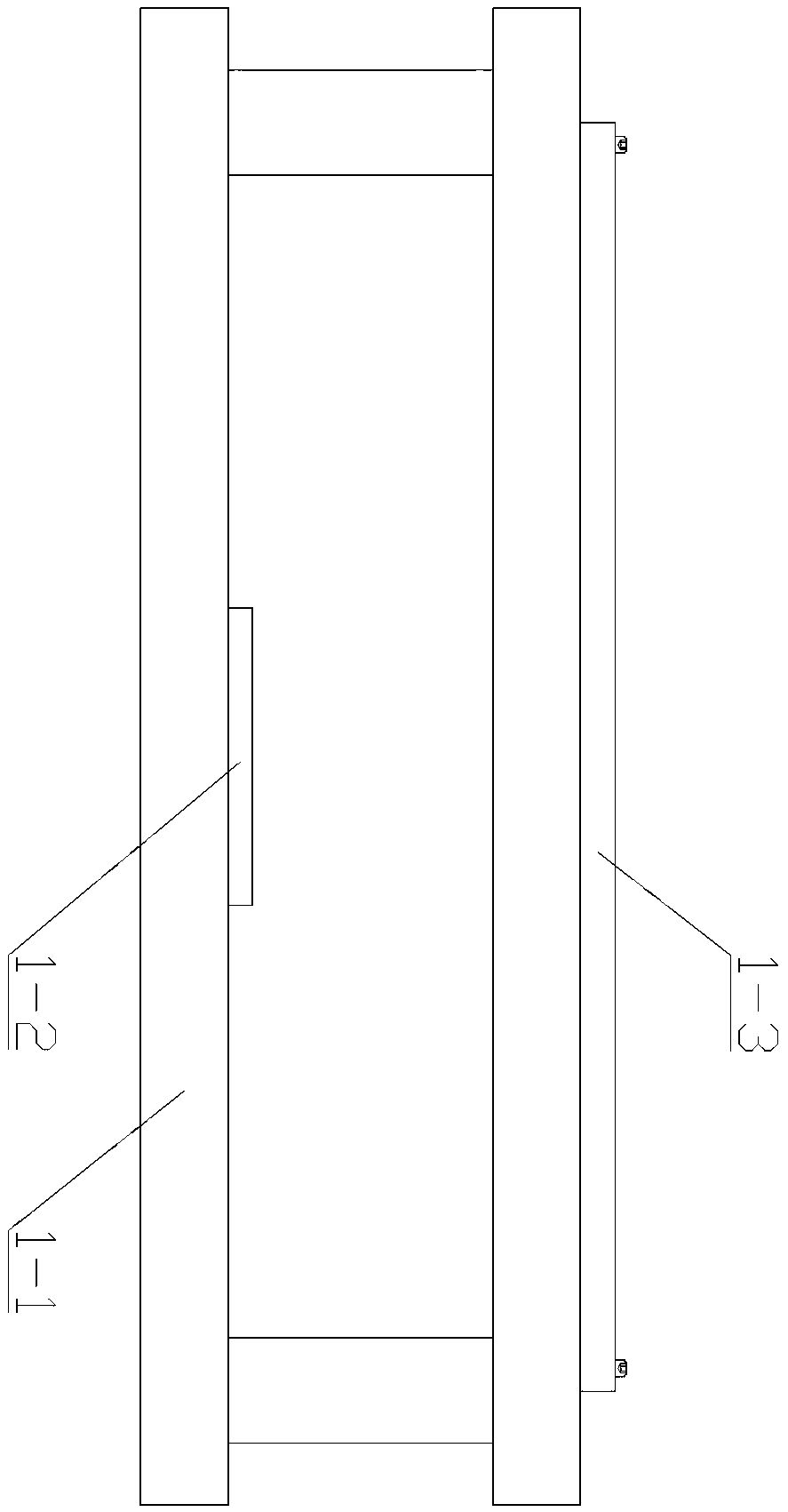

[0041] The frame 1 includes a frame-shaped frame body 1-1 composed of square steel, a bevel gear box mounting plate 1-2 and a linear guide rail 1-3, and the bevel gear box mounting plate 1-2 is fixedly installed on the frame-shaped frame body The middle part of the two rectangular steel pipes at the bottom of 1-1, and the two linear guide rails 1-3 are respectively fixedly installed on the tops of the two rectangular steel pipes at the top of the frame body 1-1.

[0042] The bevel gearbox 2 includes an input shaft 2-1 connected to the output shaft of the servo motor 9, a first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com