Hematodialysis pre-flushing waste liquid drainage tube

A technology of waste liquid discharge and hemodialysis, applied in dialysis systems, suction devices, etc., can solve problems such as waste liquid discharge, and achieve the effects of reducing environmental pollution, simple and safe pre-flushing, and reducing workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

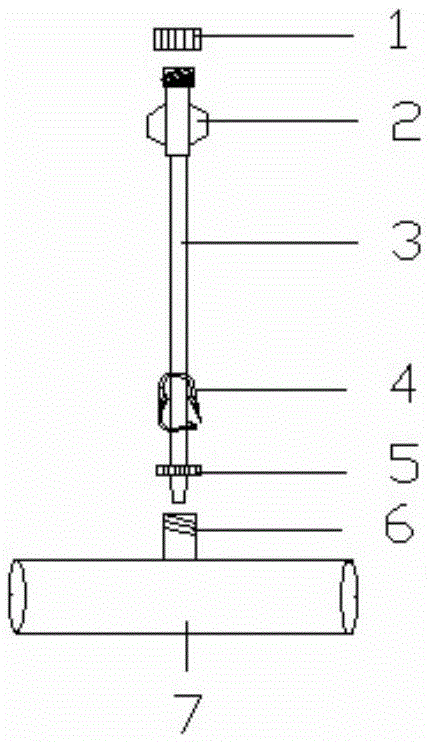

[0012] see figure 1 , a type A hemodialysis preflush waste liquid discharge tube, which is composed of a cover 1, a port 2 connected to the preflush of the blood line tube, a connecting hose 3, a clip 4, and a connecting tube 5. One end of the connecting hose 3 is connected to the blood line tube The port 2 of the preflush connection, the other end of the connecting hose 3 is connected to the connecting pipe 5, the port 2 is threaded and fits the cover 1, and the clamp 4 is arranged on the connecting hose 3 for clamping the connecting hose 3. The diameter of the connecting pipe 5 is greater than the diameter of the waste liquid discharge pipe attached to the hemodialysis machine.

[0013] Before the start of hemodialysis treatment, the nurse must pre-flush the hemodialysis circuit and dialyzer, and then connect the vascular access to establish blood circulation before hemodialysis can be performed. When preflushing the hemodialysis pipeline and the dialyzer, the original wast...

Embodiment 2

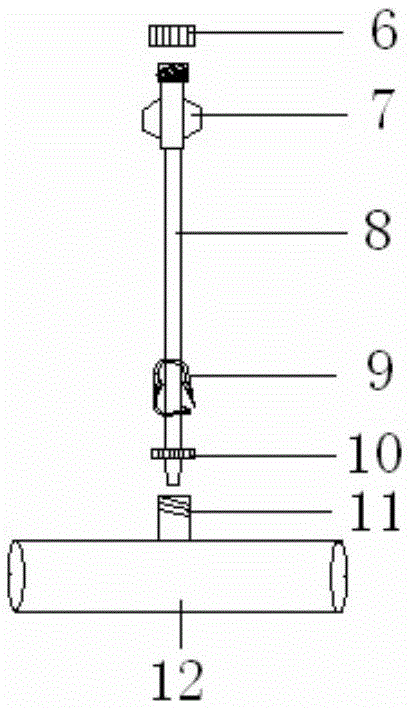

[0015] see figure 2 , a B-type hemodialysis preflush waste liquid discharge tube, consisting of a connection port cover 6, a threaded connection port 7, a waste liquid discharge connection pipe 8, a waste liquid discharge connection pipe clip 9, a fastening ring 10, and a tee joint Port 11, three-way joint 12, waste liquid discharge connecting pipe clip 9 is set on the waste liquid discharge connecting pipe 8, and the waste liquid discharge connecting pipe 8 is connected to the vertical port 11 of the three-way joint through the fastening ring 10, and the three-way joint 12 The diameters of the left and right ports are smaller than the diameters of the waste liquid discharge pipes of the hemodialysis machine.

[0016] Before the start of hemodialysis treatment, the nurse must pre-flush the hemodialysis circuit and dialyzer, and then connect the vascular access to establish blood circulation before hemodialysis can be performed. When pre-washing the hemodialysis pipeline and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com