Method for prolonging service life of refractory material of grate cooler

A technology of refractory materials and grate coolers, applied in the field of cement processing, can solve the problems of complex operation process, large construction formwork area, unreasonable structure, etc., and achieve the effect of simple operation process, small construction formwork area and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The preferred embodiments of the present invention are described below. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0027] According to an embodiment of the present invention, a method for prolonging the service life of the refractory material of the grate cooler is provided.

[0028] The technical scheme of the present invention can prolong the service life of the refractory material of the grate cooler, and the service life of the refractory material of the grate cooler reaches 8 months.

[0029] Countermeasures for formulating the technical solution of the present invention:

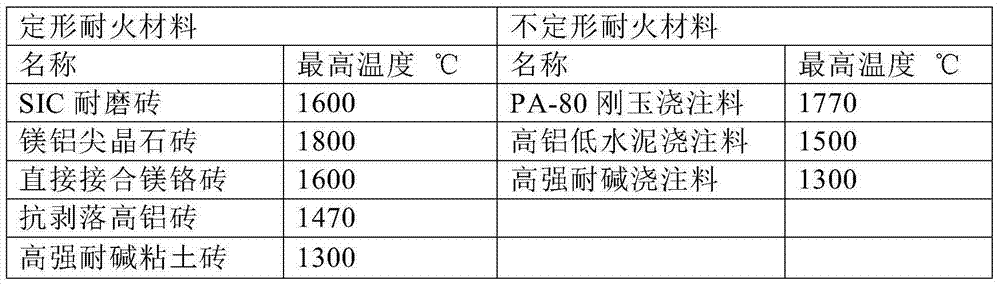

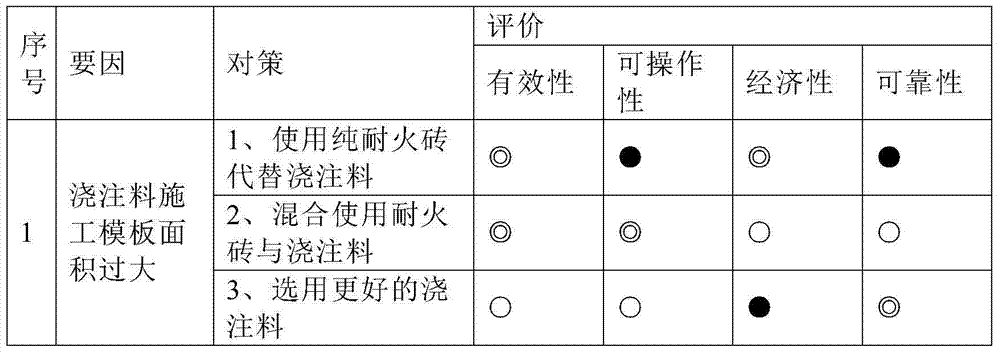

[0030]

[0031] Note: ○-5 points ◎-3 points ●-1 point

[0032]

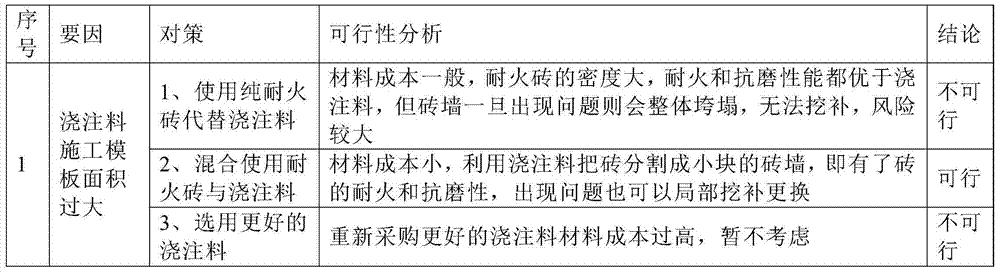

[0033] Countermeasure implementation plan:

[0034]

[0035] Implementation of technical solution countermeasures of the present invention:

[0036] Countermeasure implementat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com