Single-motor-driven all-electric mold closing and moving system and implementation method and application thereof

A single-motor-driven, all-electric technology, applied in the field of electric mold clamping and mold shifting systems, can solve the problems of increasing manufacturing costs, affecting service life, serious heat generation, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

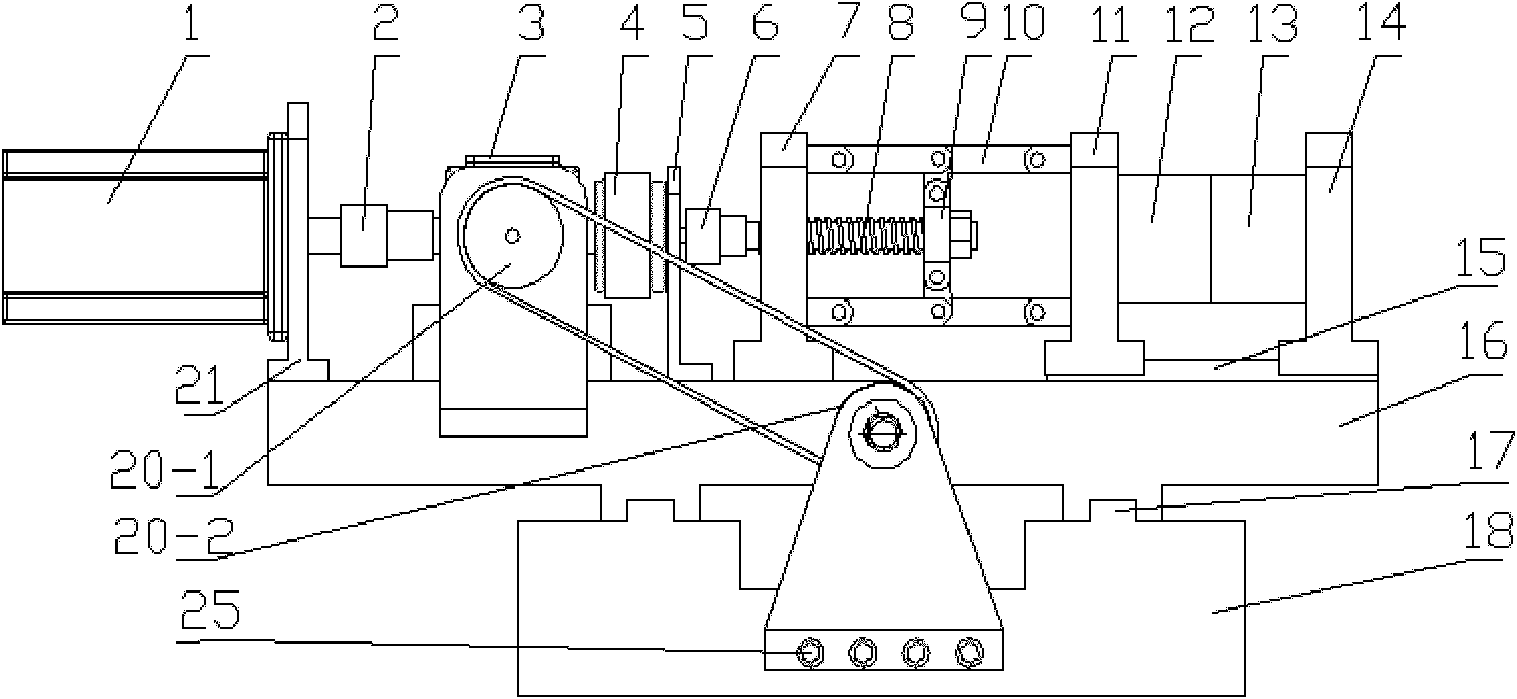

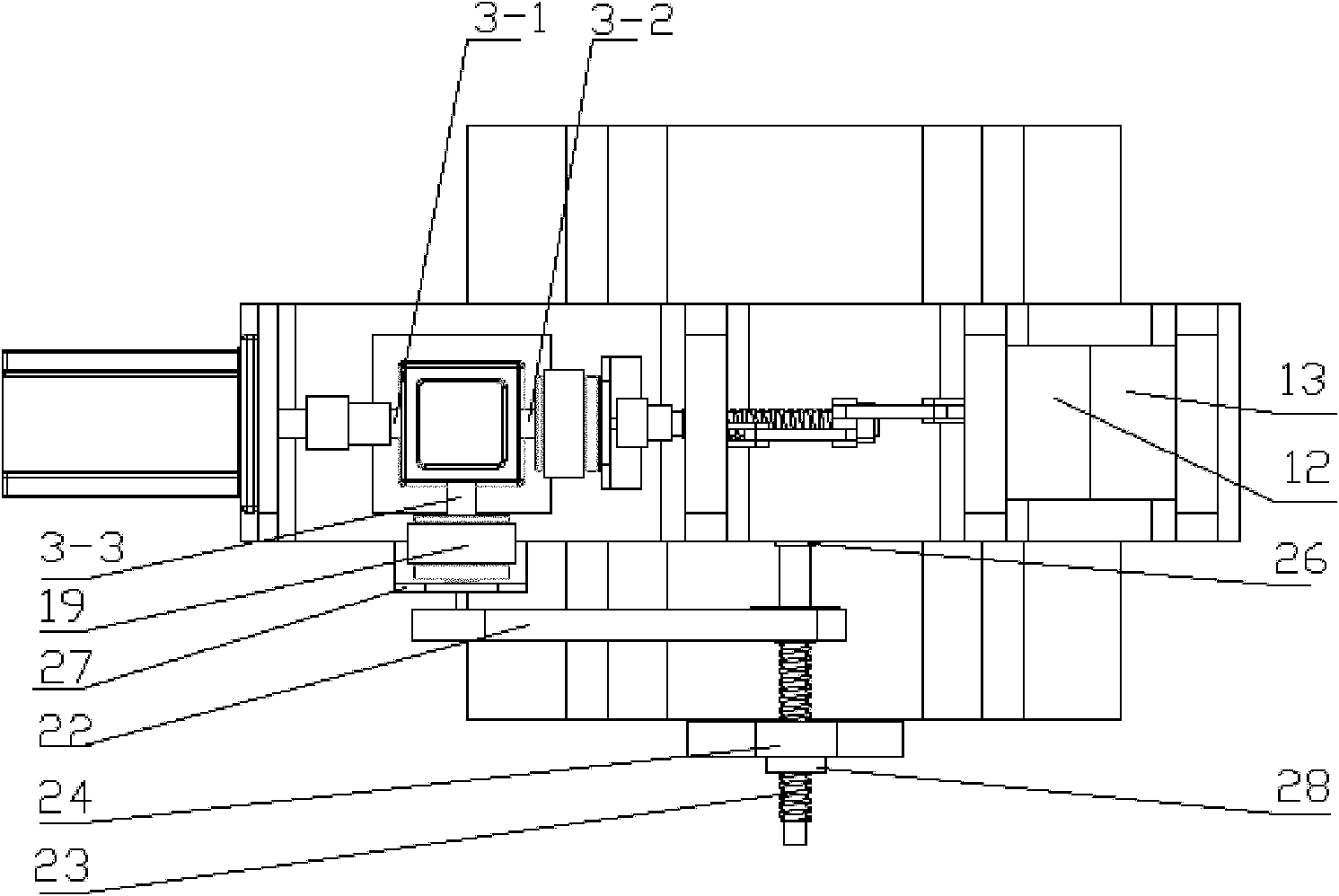

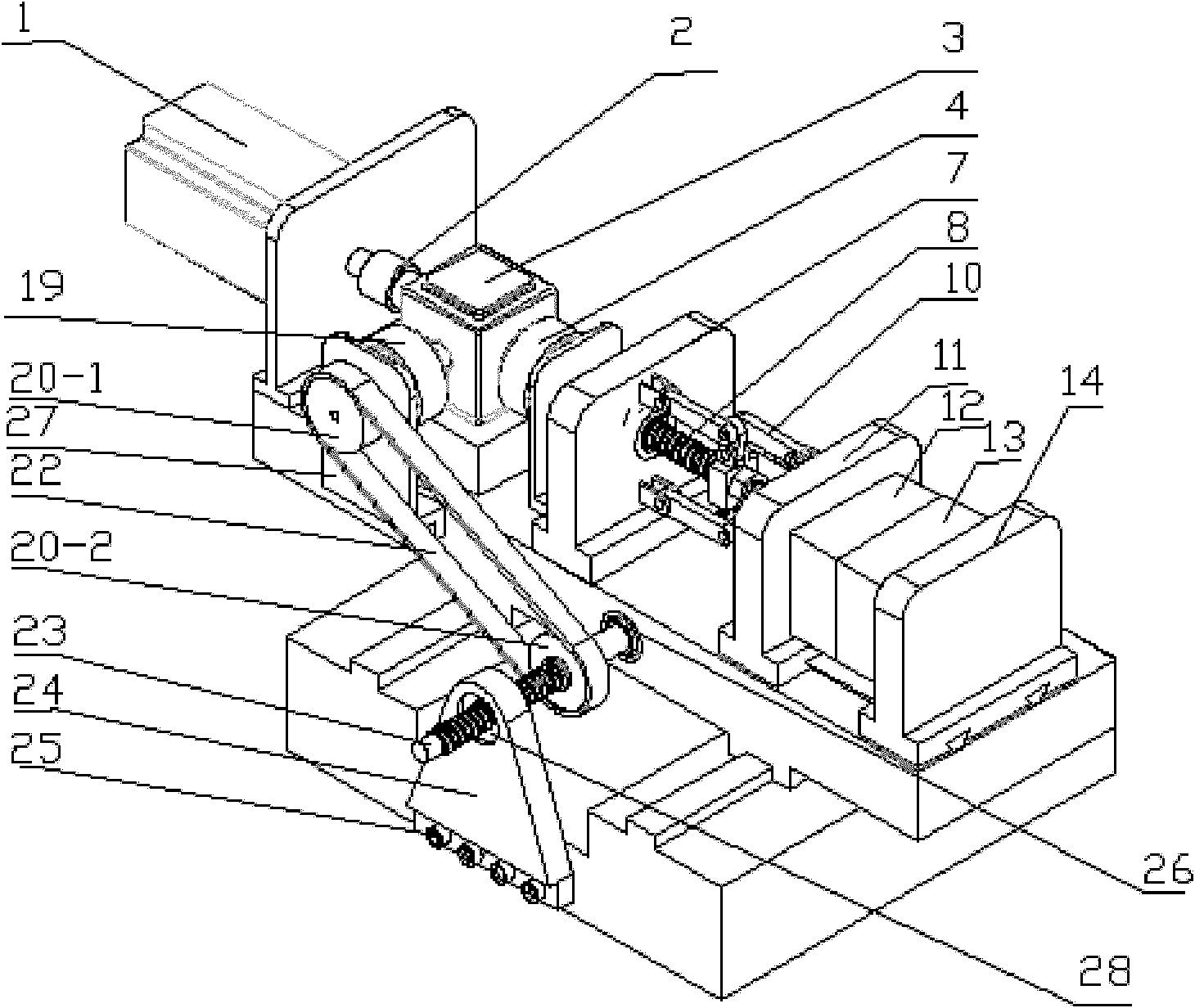

[0030] Figure 1 to Figure 4 The specific structure of the all-electric mold clamping and mold moving system driven by a single motor of the present invention is shown. Depend on figure 1 and figure 2 It can be seen that the all-electric mold clamping and mold moving system driven by a single motor includes a motor 1, a main coupling 2, a steering gear 3, a mold clamping clutch 4, a mold moving clutch 19, a mold clamping coupling 6, a support plate 7, Moving template 11, fixed template 14, clamping ball screw 8, moving mold ball screw 23, timing belt 22, bearing plate 16 and base 18 etc.

[0031] The motor 1 is installed on the plate 21, the output shaft of the motor 1 is connected with the input end 3-1 of the steering gear 3 through the main coupling 2, and the lateral output end 3-2 of the steering gear 3 is connected with the clamping clutch 4, The mold clamping clutch 4 is fixed on the support plate 5, and the output end of the mold clamping clutch 4 is connected with...

Embodiment 2

[0037] This embodiment is the same as Embodiment 1 except for the following features: the steering gear of this single-motor-driven all-electric mold clamping and mold moving system has three output terminals, and is connected to two sets of mold clamping and mold moving devices at the same time to realize double-station mold clamping .

Embodiment 3

[0039] This embodiment is the same as embodiment 1 except the following features: do not start the mold moving device, only start the mold clamping device, complete the unidirectional mold clamping and locking operation, and can be used for the mold clamping process of the electric injection molding machine (this process does not need mold shifting).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com