Method for preparing thermoplastic elastomer by supercritical fluid assisted dynamic vulcanization

A thermoplastic elastomer and supercritical fluid technology, which is applied in the production of bulk chemicals, etc., can solve the problems such as the method and application of SCF auxiliary polymer, which is easy to realize and popularize, improve mechanical properties, and reasonable operation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

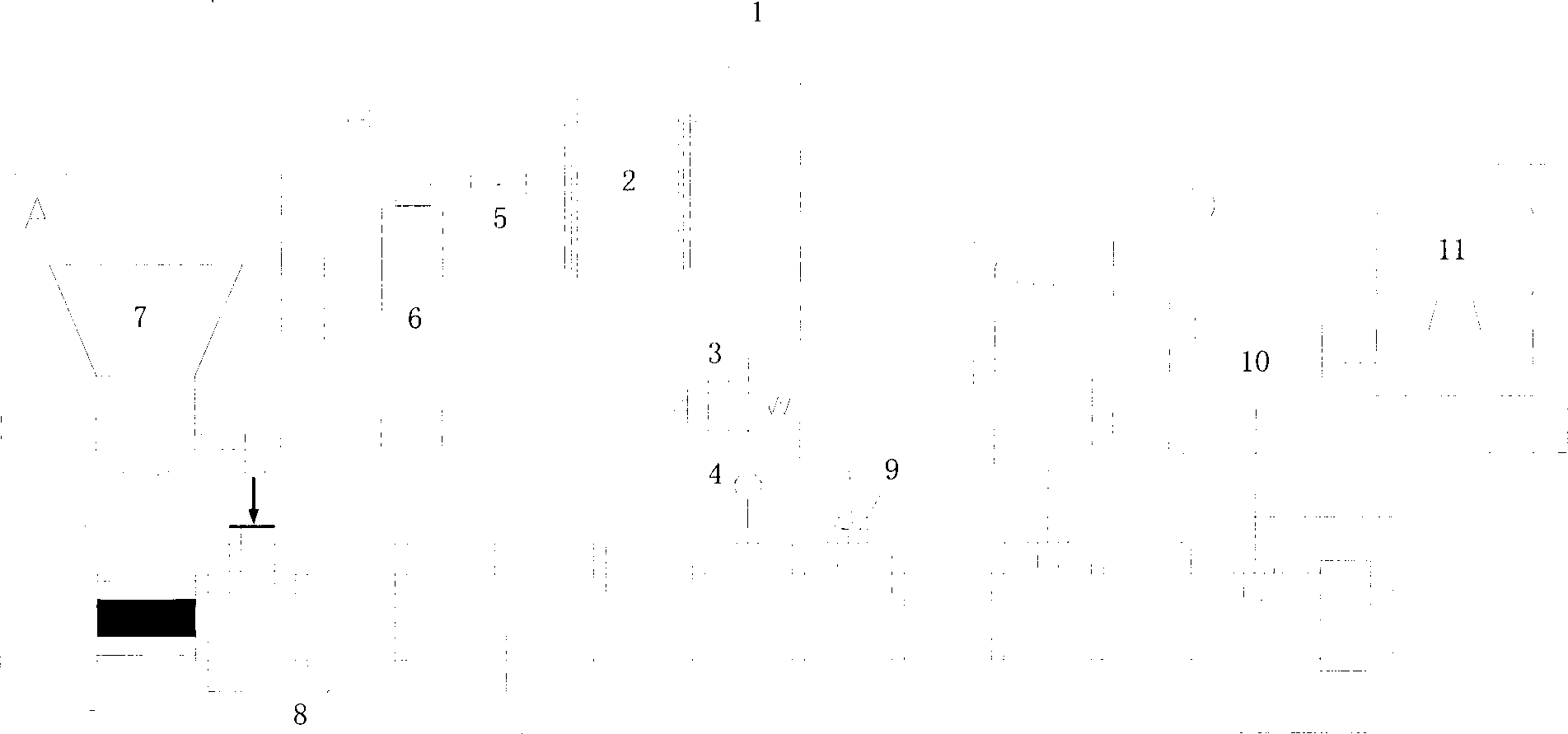

[0027] figure 1 Show the concrete structure that realizes the inventive method to carry out plastics / rubber dynamic vulcanization with twin-screw extruder, by figure 1 It can be seen that the SCF-assisted polymer reaction molding processing equipment includes twin-screw extruder A, supercritical CO 2 Delivery system B, vacuum pump C and online rheological system D; supercritical CO 2The delivery system B is connected with the self-locking gas injection check valve 4; the self-locking gas injection check valve 4, the pressure sensor 9, the vacuum pump C and the online rheological system D are sequentially connected with the twin-screw extruder A along the extrusion direction. connect. Described twin-screw extruder A comprises feeder 7, machine barrel 8, screw rod (not shown in the figure) and pressure sensor 9, the rear end of machine barrel 8 links to each other with feeder 7, and the periphery of machine barrel 8 There is a temperature control heating ring (not shown in th...

Embodiment 2

[0039] (1) Weigh 20 parts of polypropylene, 80 parts of EPDM rubber, 5 parts of sulfur, 1 part of accelerator CZ (N-cycloethyl-2-benzothiazole sulfenic acid amine), 2 parts of accelerator Agent DM (dibenzothiazole disulfide), 4 parts of stearic acid, 8 parts of zinc oxide, mixed together.

[0040] (2) Add the mixture in the step (1) to continuous supercritical carbon dioxide assisted polymer extrusion equipment, under the conditions that the supercritical carbon dioxide content is 2.5% of the total mass of the material, the reaction extrusion temperature is 160 ° C, and the extrusion time is 7 minutes Next, the polypropylene / EPDM thermoplastic elastomer can be obtained by extruding through the machine head.

Embodiment 3

[0042] (1) Weigh 60 parts of polypropylene, 40 parts of nitrile rubber (NBR), 4 parts of dicumyl peroxide, 4 parts of stearic acid, and 8 parts of zinc oxide and mix them together.

[0043] (2) Add the mixture in the step (1) to continuous supercritical carbon dioxide assisted polymer extrusion equipment, under the conditions that the supercritical carbon dioxide content is 1.5% of the total mass of the material, the reaction extrusion temperature is 180 ° C, and the extrusion time is 10 minutes Next, the polypropylene / nitrile rubber thermoplastic elastomer can be obtained by extruding through the machine head.

[0044] It can be seen from Table 3 that the supercritical CO 2 During the preparation of PP / NBR thermoplastic elastomers by assisted dynamic vulcanization, the motor current of the extruder was in supercritical CO 2 In the case of joining, there is a relatively large decrease.

[0045] Table 3 Motor current of PP / NBR(60 / 40) thermoplastic elastomer during preparation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com