Porous stay tube, preparation method and application

A technology of porous support and manufacturing method, applied in the direction of slender elements, building elements, etc., can solve the problems that the support position needs to be changed, the support structure cannot be applied well, the support structure cannot be used, and it is unfavorable for popularization and use, and the product quality is stable. The effect of good performance, improved support strength and strong rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

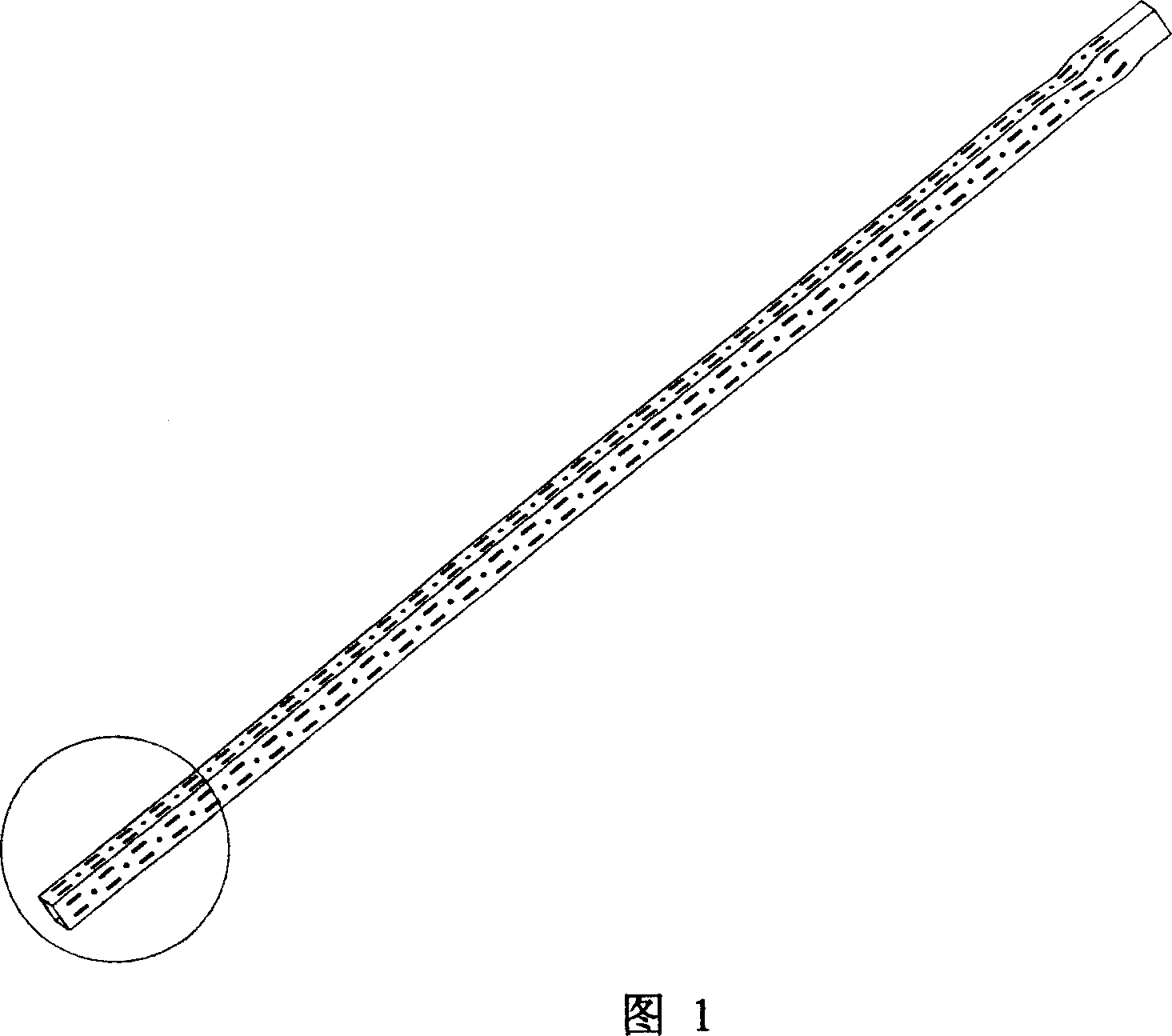

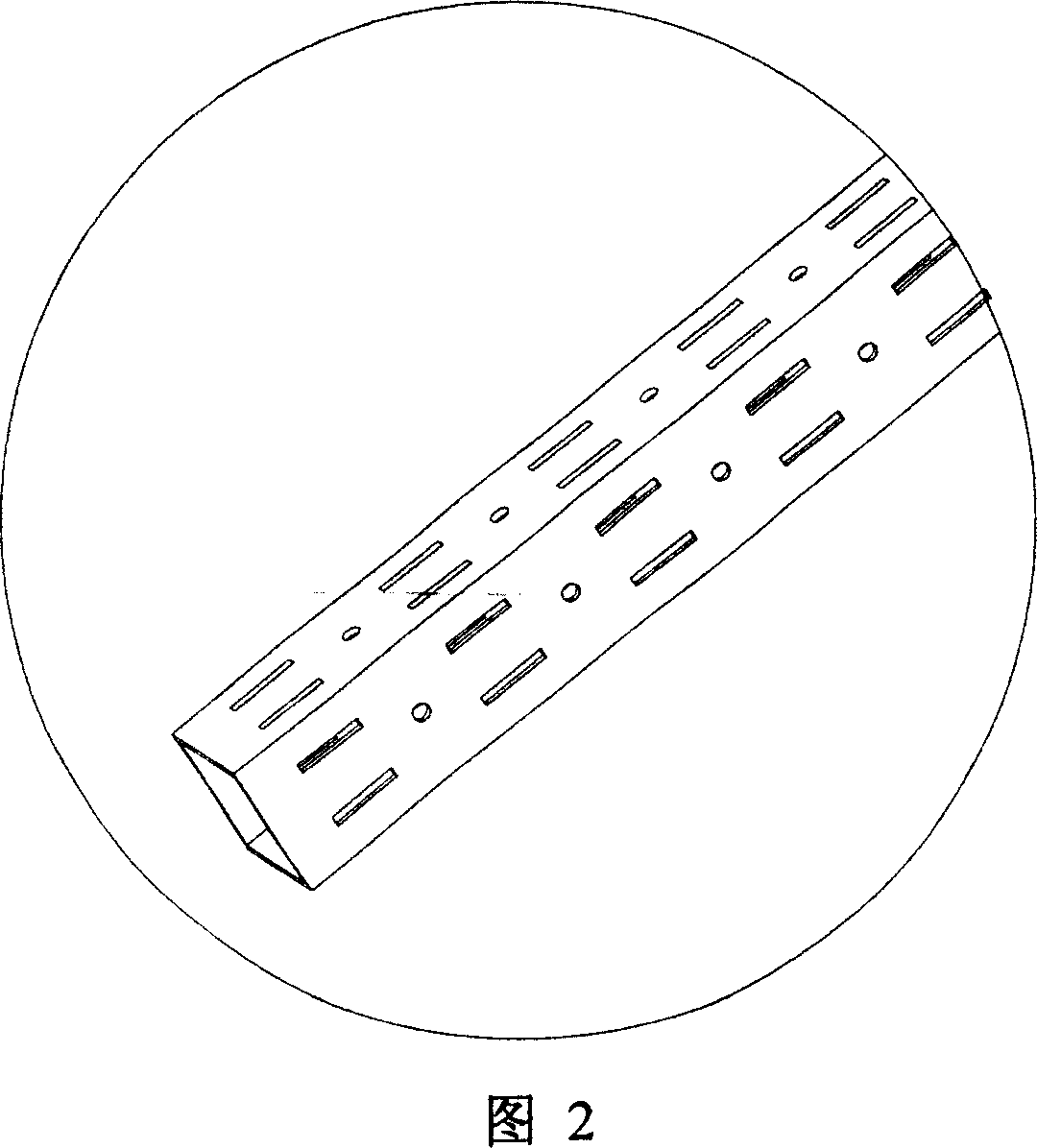

[0035] Fig. 1 and Fig. 2 have shown the specific structure of the present invention, as seen from Fig. 1, this porous support pipe comprises hollow pipe body, and the cross section of pipe body is square, and the four wall surfaces of described pipe body are integrally uniformly provided with for supporting Fixed through holes, the shape of the through holes is rectangular and circular, as shown in Figure 2; the through holes on each wall of the pipe body are arranged in the middle of the wall in the form of two parallel rows, and the position of the through holes on the opposite wall of the pipe body Symmetrical setting.

[0036] The method for manufacturing above-mentioned porous support pipe comprises the following steps:

[0037] (1) Continuous punching on the strip: cut the strip according to the size of the total section of the pipe body, and then put the cut strip into the punching machine for punching.

[0038] (2) Bending the punched strip, and butt joint shaping to ...

Embodiment 2

[0043] The structure of this porous support pipe is with the embodiment 1 shown in Fig. 1 and Fig. 2; Its manufacture method comprises the following steps:

[0044] (1) Continuous punching on the strip: Put a whole piece of plate into the punching machine for punching, and then cut the strip required for manufacturing a single pipe according to the size of the total section of the pipe body.

[0045] (2) The punched strip is rolled and formed by a rolling machine to form a pipe profile with a butt joint.

[0046](3) The butt joints of the pipe profiles are welded to form hollow porous support pipes. The specific welding process is to clamp and fix the pipe profile and place it in water or other cooling liquid, leaving only the butt joint on the water surface or the cooling liquid surface; at the same time, a cooling nozzle is installed behind the welding torch. Move, spray water or coolant to cool the solder joints immediately to prevent the pipe profile from twisting or shri...

Embodiment 3

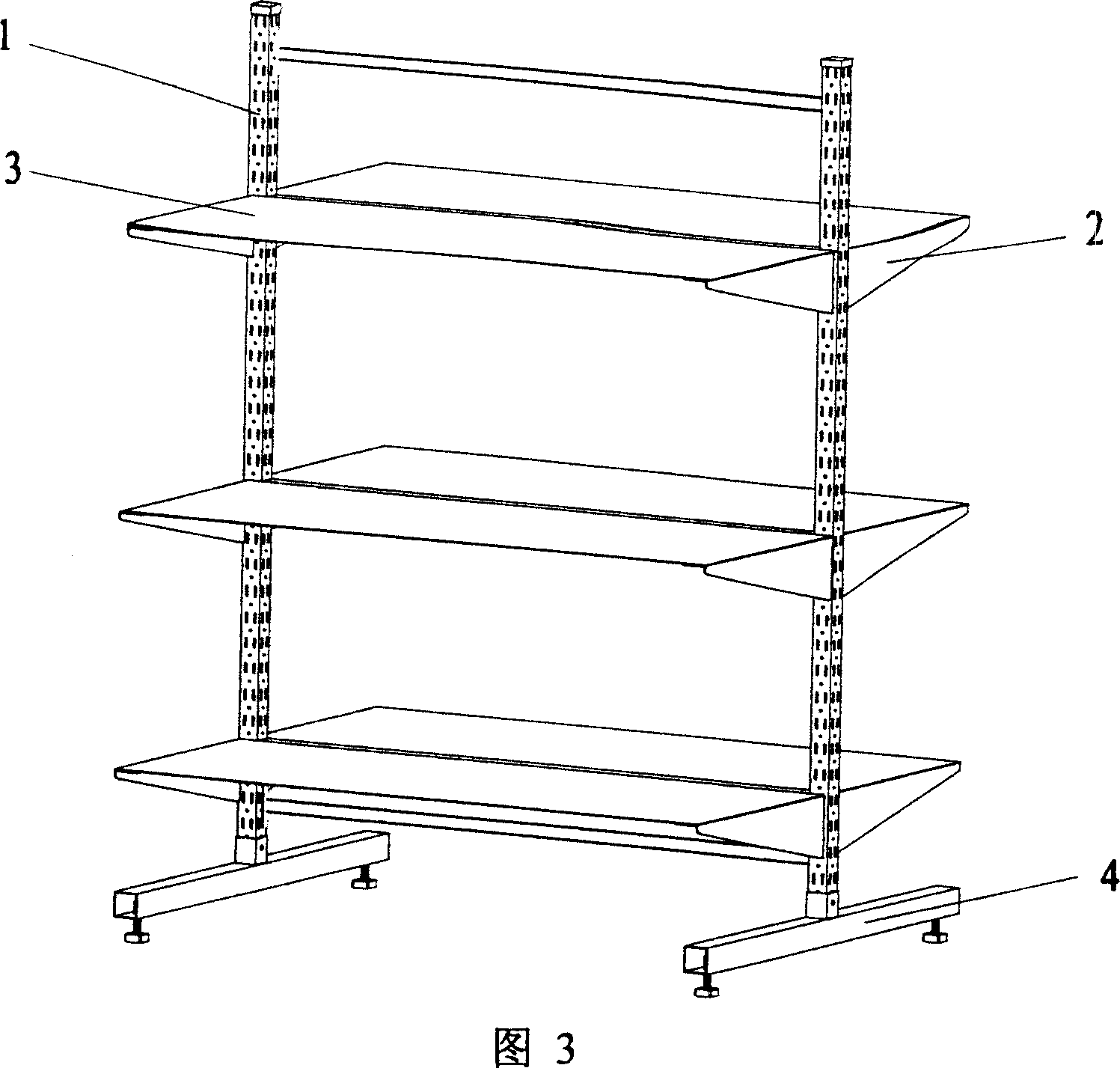

[0050] The structure and manufacturing method of the porous support tube of this embodiment are the same as those in Example 1. The structure of its application is shown in Figure 5. The porous support tube can be used to form a telescopic support structure. As can be seen from Figure 5, the porous support tube includes two section sections. For the porous support tubes 1-1 and 1-2 of different sizes, the section 1-1 with a smaller section is inserted into the section 1-2 with a larger section, but the size and position of the holes set in the two sections of porous support tubes Correspondingly, the clamping block 7 can be used to snap into the corresponding holes of the two sections of porous support tubes 1-1, 1-2 that are socketed together, and the relative positions of the two sections of porous support tubes 1-1, 1-2 can be checked. fixed. When the block 7 is pulled out, the relative position between the two sections of porous support tubes 1-1, 1-2 can be adjusted relat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com