Device for producing methyl isocyanate from dimethyl sulfate and continuous process

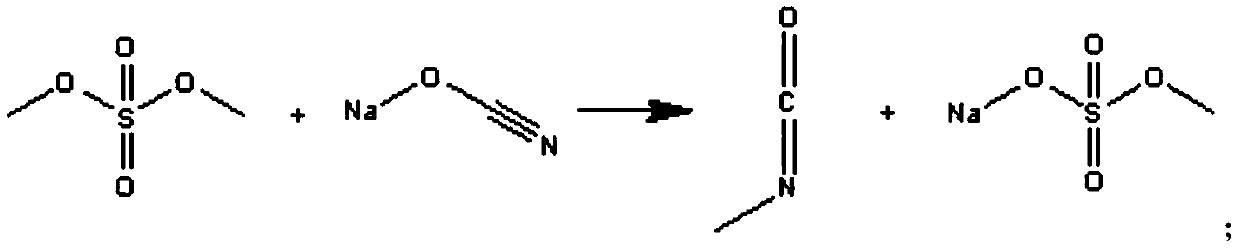

A technology of methyl isocyanate and dimethyl sulfate, applied in the purification/separation of isocyanic acid derivatives, preparation of isocyanic acid derivatives, organic chemistry, etc., can solve problems affecting the safety of environmental workers and avoid side effects Responsive, reasonable overall design, simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

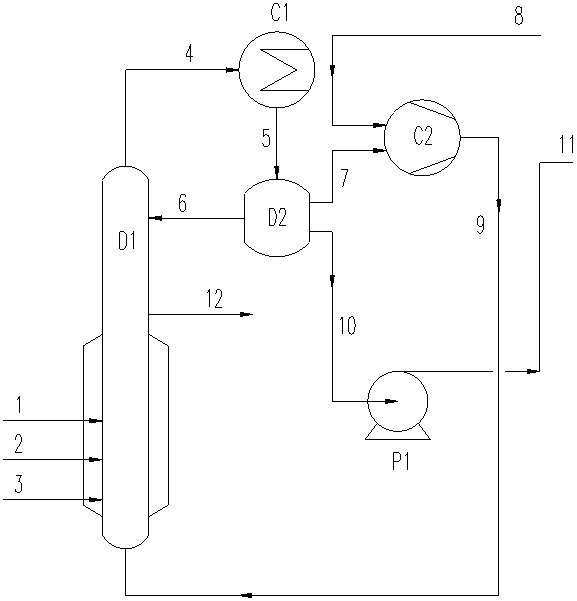

[0029] like figure 1 Shown, a kind of device that dimethyl sulfate produces methyl isocyanate, it comprises methyl isocyanate reactor D1, and described methyl isocyanate reactor D1 is connected with raw material solvent oil feed line 1, Sodium cyanate feed line 2 and dimethyl sulfate feed line 3, described methyl isocyanate reactor D1 is connected with methyl isocyanate condenser C1 by product discharge line 4 after reaction, described isocyanate Acetate methyl ester condenser C1 is connected with gas-liquid separation tank D2 through condensed mixture delivery line 5; Said gas-liquid separation tank D2 is connected with said methyl isocyanate reactor D1 through circulating solvent oil delivery line 6, said After the gas-liquid separation tank D2 is separated from the gas-liquid, the nitrogen delivery pipeline 7 is connected with a nitrogen compressor C2, and the nitrogen compressor C2 is connected with a nitrogen inlet pipeline 8, and the nitrogen compressor C2 is connected w...

Embodiment 2

[0032] like figure 1Shown, a kind of device that dimethyl sulfate produces methyl isocyanate, it comprises methyl isocyanate reactor D1, and described methyl isocyanate reactor D1 is connected with raw material solvent oil feed line 1, Sodium cyanate feed line 2 and dimethyl sulfate feed line 3, described methyl isocyanate reactor D1 is connected with methyl isocyanate condenser C1 by product discharge line 4 after reaction, described isocyanate Acetate methyl ester condenser C1 is connected with gas-liquid separation tank D2 through condensed mixture delivery line 5; Said gas-liquid separation tank D2 is connected with said methyl isocyanate reactor D1 through circulating solvent oil delivery line 6, said After the gas-liquid separation tank D2 is separated from the gas-liquid, the nitrogen delivery pipeline 7 is connected with a nitrogen compressor C2, and the nitrogen compressor C2 is connected with a nitrogen inlet pipeline 8, and the nitrogen compressor C2 is connected wi...

Embodiment 3

[0042] A kind of dimethyl sulfate is produced the continuous process of methyl isocyanate, it has used above-mentioned such as figure 1 A kind of dimethyl sulfate shown produces the device of methyl isocyanate, can adopt following steps:

[0043] 180# solvent oil enters described methyl isocyanate reactor D1 with 2000g / h, sodium cyanate through raw material solvent oil feed line 1 and sodium cyanate feed line 2 respectively with the speed of 267g / h, dimethyl sulfate Ester enters the methyl isocyanate reactor D1 through the dimethyl sulfate feed line 3 at a speed of 323g / h, and the reaction temperature is controlled at 180° C. through the jacket; nitrogen passes through the nitrogen compressor C2 to The speed of 6L / h enters the described methyl isocyanate reactor D1; the material that has reacted enters the described methyl isocyanate condenser C1 through the product discharge pipeline 4 after the reaction, and controls the methyl isocyanate The outlet temperature of the ester...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com