Water needle applied for water shaping production

A water-needle and water-assisted technology, applied in the field of plastic hollow injection molding production systems, can solve unseen problems, achieve the effects of easy standardization, improve dynamic performance, and ensure product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

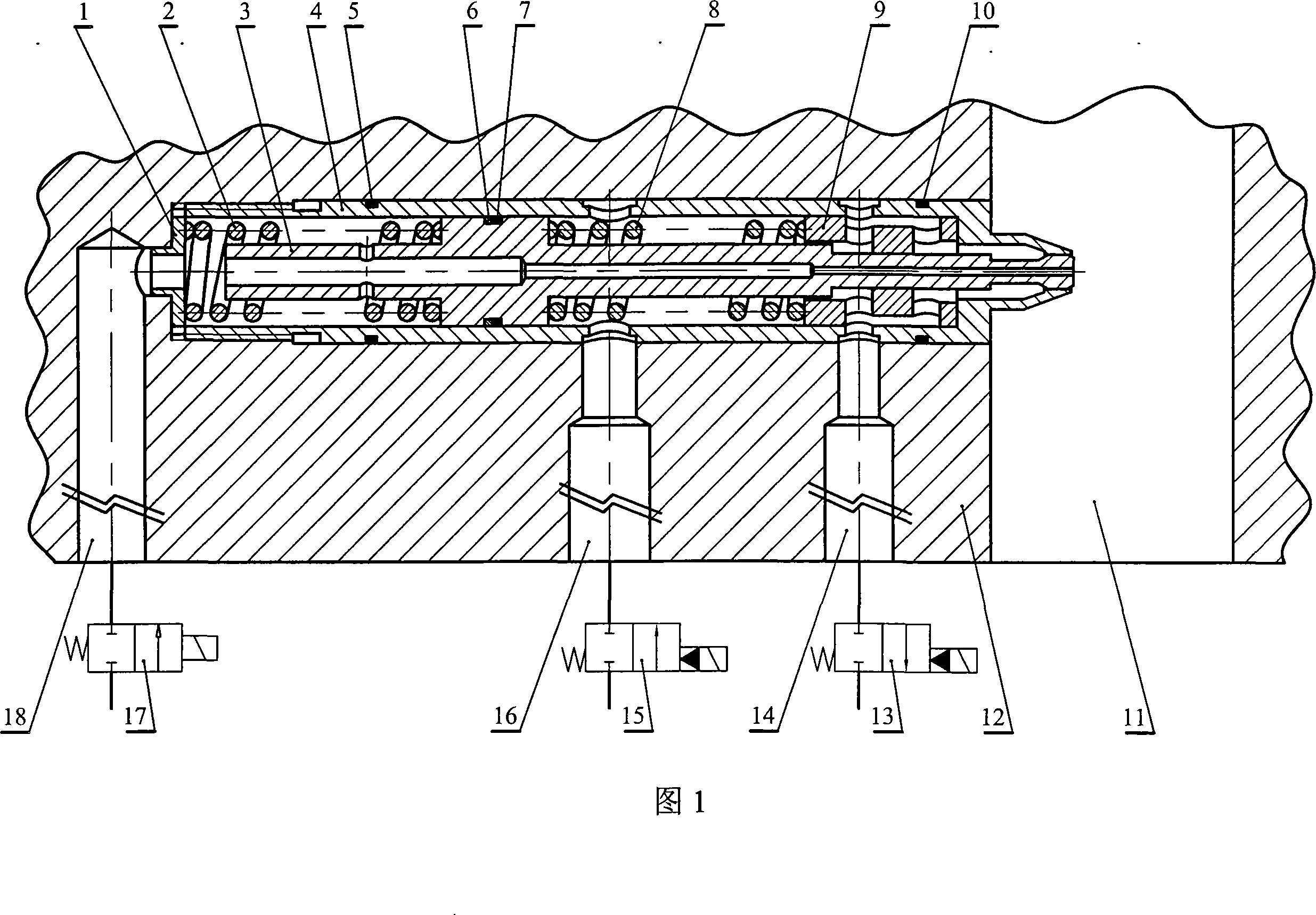

[0021] As shown in Figure 1, the water needle used in the water-assisted molding production of the present invention includes: a core rod 3, a needle sleeve 4, springs 2 and 8, a support limit ring 1, a diversion limit ring 9, and an O-ring 5 And 10, retaining ring 6 and O-ring 7. The support limit ring 1 and the needle cover 4 are installed in the water needle installation hole of the mold 12, the tapered small end of the needle cover 4 protrudes into the cavity 11 of the mold 12, and the small right end of the needle cover 4 extends into the cavity 11 The part is tapered, which makes it easy to take out the workpiece and reduces the marks on the surface of the workpiece. The needle sleeve 4 is equipped with a hollow core rod 3 with a large middle diameter and small ends. 4 forms a sliding fit, and one end of the core rod 3 and the protruding end of the needle cover 4 also form a sliding fit, and have a sealing effect, sealing the passage of the water in the needle cover 4 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com