Water-assisted (co-injection) injection mold for complex-formed tube and stick plastic parts

An injection mold, water-assisted technology, applied in the field of injection molds, can solve the problems of no measures for preventing backflow of runners, and achieve the effects of stable water injection and production cost savings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing:

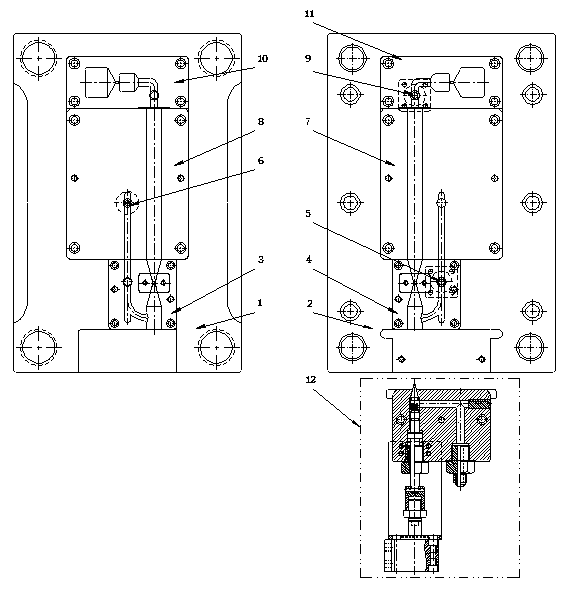

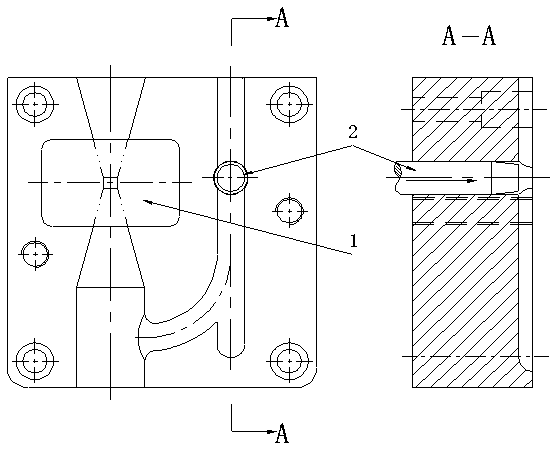

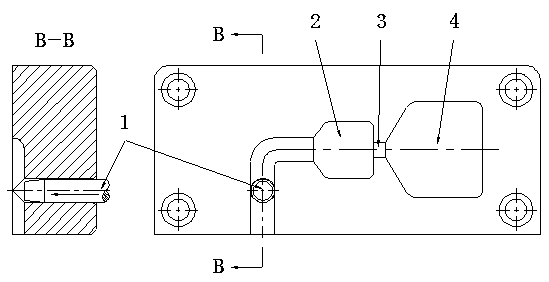

[0018] Such as figure 1 As shown, a water-assisted (co)injection mold includes a movable mold body (1), a fixed mold body (2), a movable mold gate insert (3), a fixed mold gate insert (4), a runner seal Needle (5), sprue sleeve (6), movable mold cavity insert (7), fixed mold cavity insert (8), fixed mold overflow cavity insert (9), overflow channel sealing pin (10), The overflow chamber insert (11) and the water needle (12) of the movable mold. The installation position of the water needle (12) is selected near the ground side of the moving mold parting surface to avoid mold damage caused by water leakage, and the water injection port is aligned with the gate, that is, the axial direction of the pipe fitting, so as to avoid water flow from the side of the cavity. The sharp steering leads to the problem of eccentric penetration of the front section and instability of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com