Construction method for assisting in sinking of open caisson through high-pressure water

A construction method and high-pressure water technology, applied in the direction of caisson, infrastructure engineering, construction, etc., can solve the problems of delayed construction period and low sinking efficiency, and achieve the effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with specific embodiment, further illustrate the present invention.

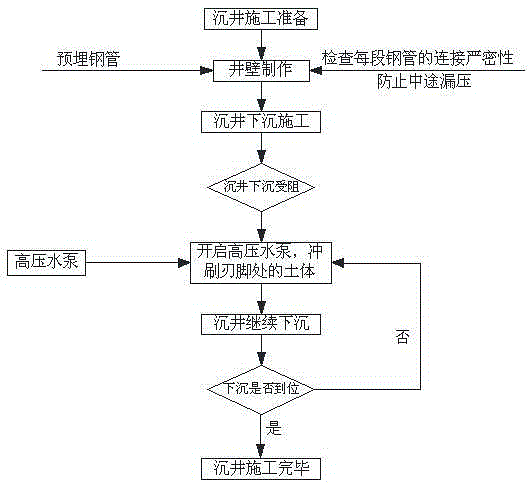

[0016] Such as figure 1 Shown, a kind of caisson high-pressure water-assisted construction method comprises the following steps:

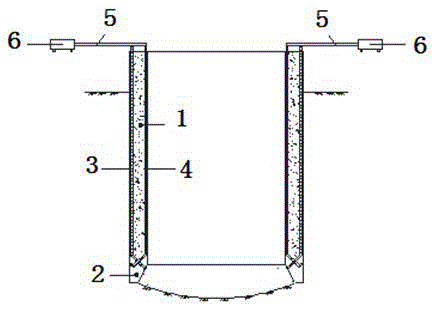

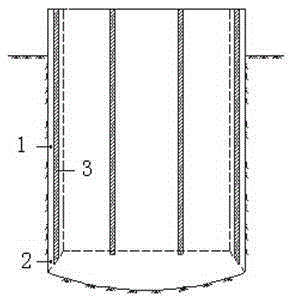

[0017] ① When making the caisson well wall, install steel pipes on both sides of the well wall in advance. The steel pipes should be evenly installed along the well wall and should extend from top to bottom to the edge of the blade;

[0018] ②If the sinking is blocked, press high-pressure water into the steel pipe through the high-pressure water pump at the upper port of each steel pipe to destroy the soil inside and outside the caisson blade foot, and reduce the sinking resistance;

[0019] ③ Check whether the caisson is sunk in place, if not, return to step ② until the caisson sinks in place.

[0020] The diameter of the steel pipe used is 40mm-120mm, and the water outlet of the steel pipe is 100mm-300mm away from the bottom end of the blade foot. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com