Movable core type squirt cut device applied to water-assisted injection molding

A technology of injection molding and movable core, applied in the field of movable core type water needle device, can solve the problems of high cost of water needle, complicated process, difficult to realize industrialized production, etc., and achieve the effect of improving the molding effect, good workmanship and easy standardization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

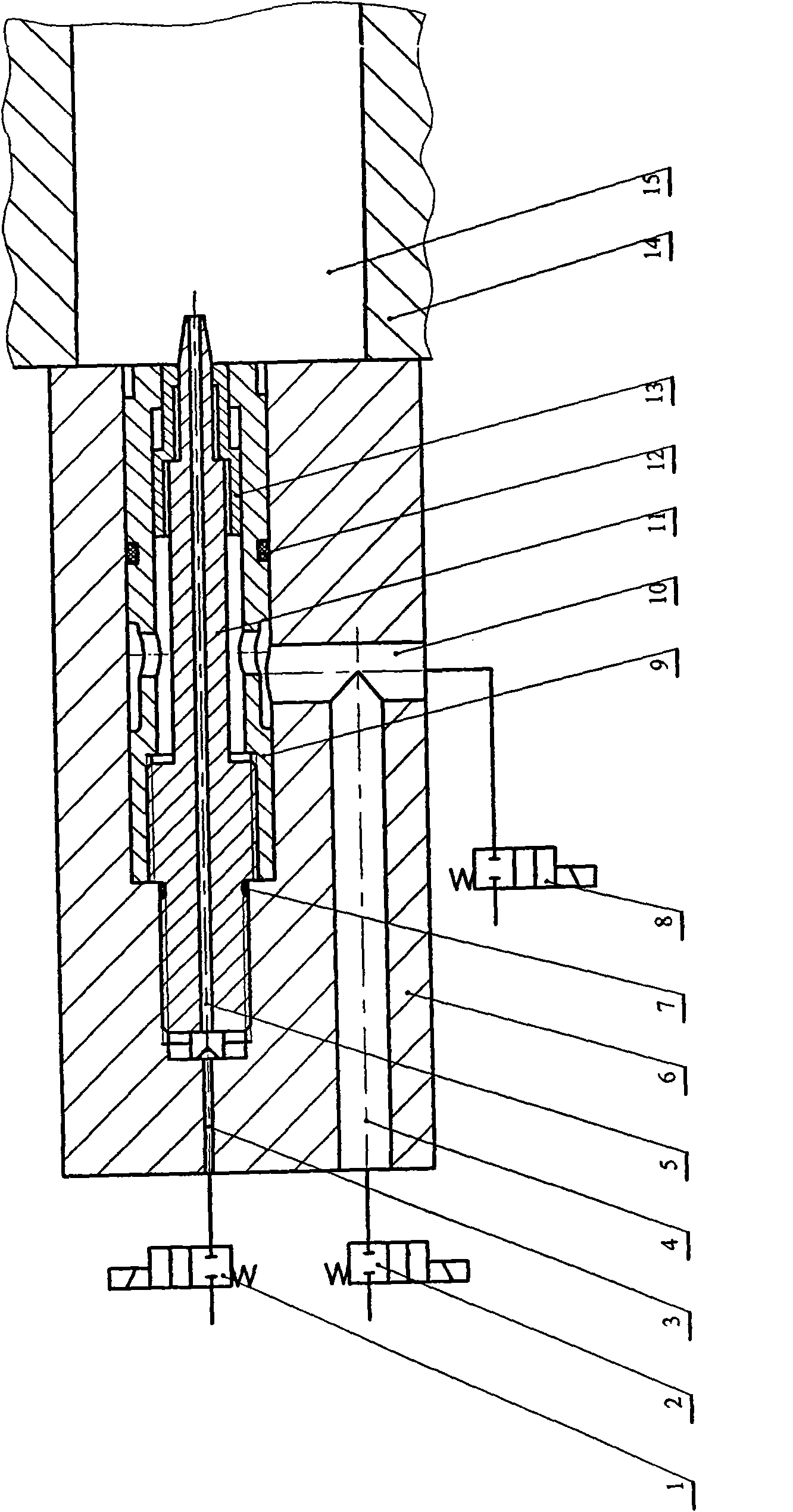

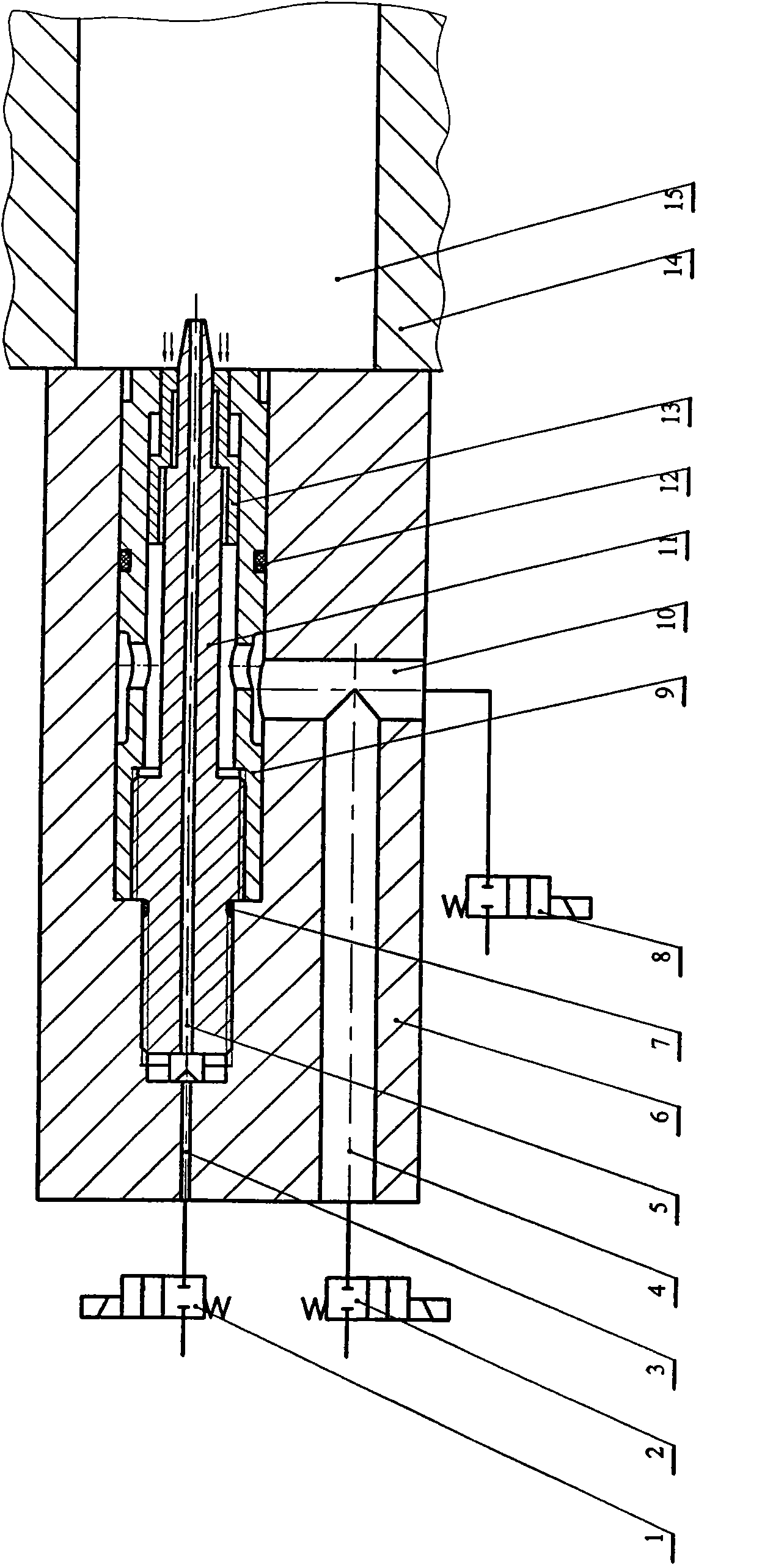

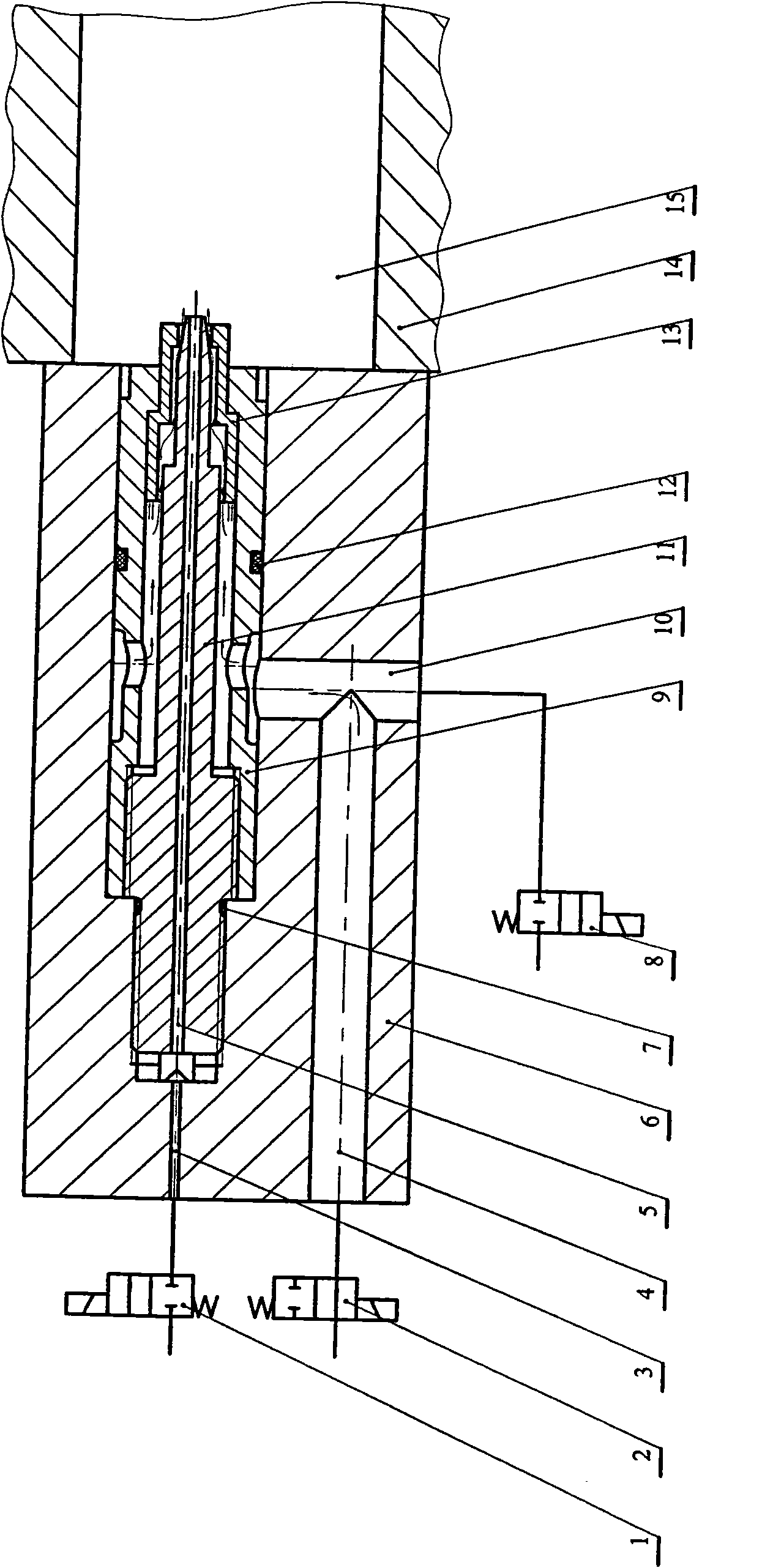

[0025] like figure 1 As shown, the present invention includes a water needle installation block 6, a movable core type water needle, an air pressure electromagnetic switch valve 1 and two water pressure electromagnetic switch valves 2, 8; wherein:

[0026] 1) The water needle installation block 6 is axially opened with a water inlet flow channel 4, an air inlet flow channel 3, and a movable core-type water needle installation hole with a small end connected to the air intake flow channel 3 and a large one at the other end. The water needle installation block 6 There is a drainage channel 10 in the inner radial direction, and the drainage channel 10 is connected with the water inlet channel 4 and the large movable core type water needle installation hole at the right end. Connected to the water inlet channel 4, the second water pressure electromagnetic switch valve 8 is connected to the drain channel 10;

[0027] 2) Movable core type water needle: including needle sheath 9, ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com