Method of extracting abalone protein peptides by subcritical water assisted enzymolysis and product

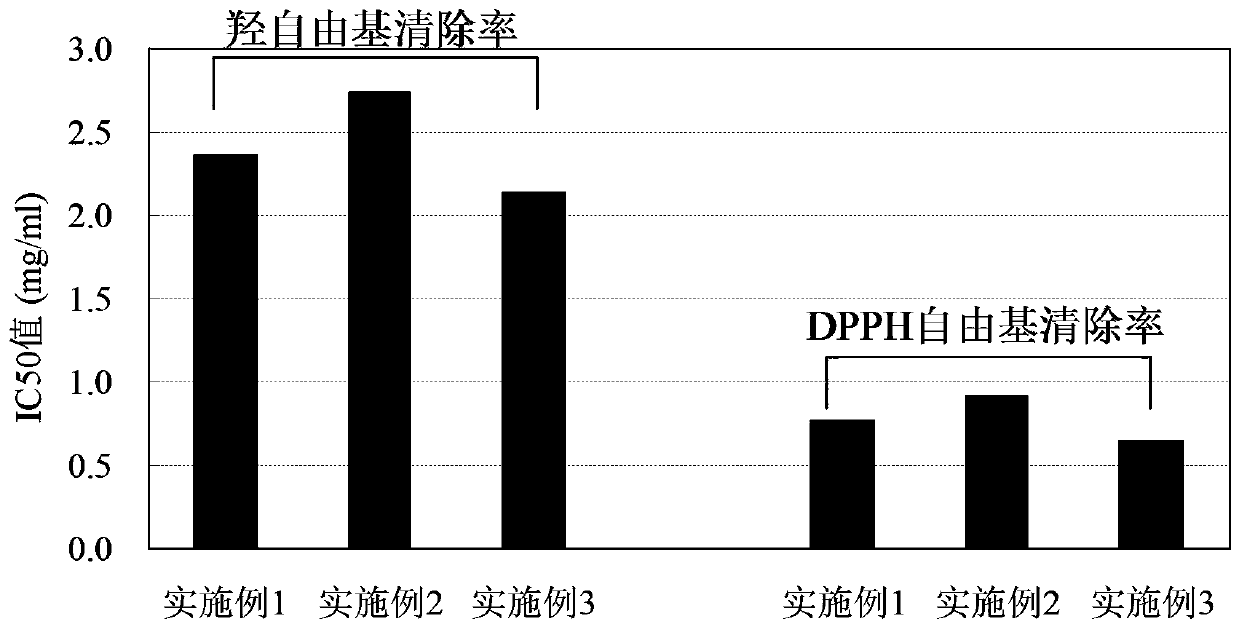

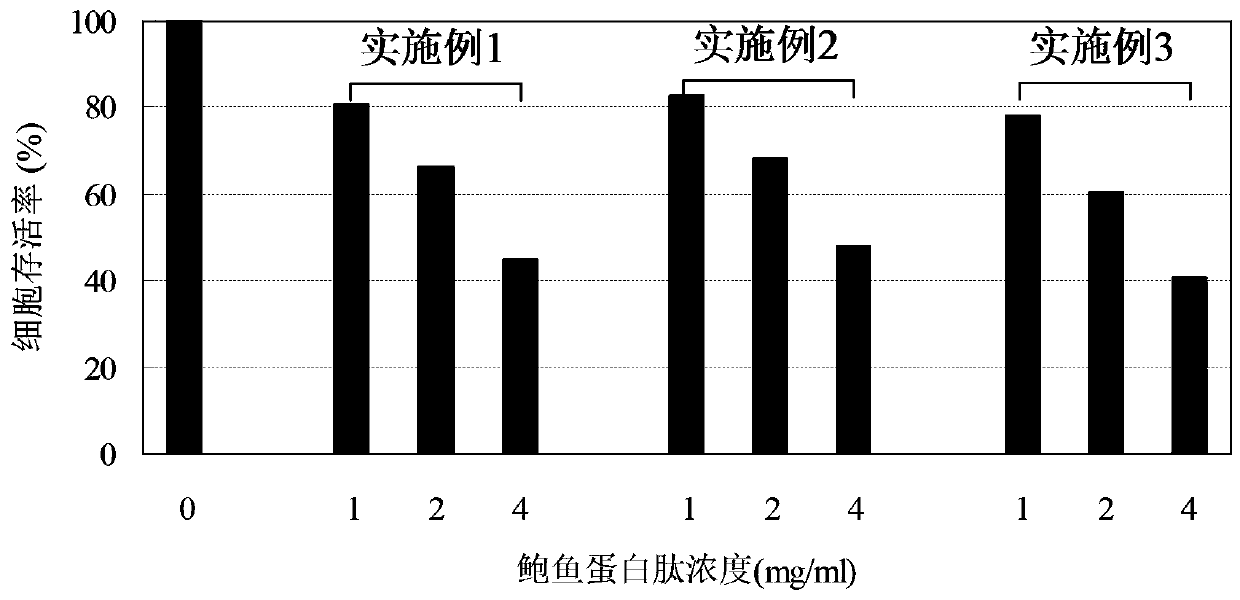

A subcritical water-assisted enzymatic hydrolysis technology, which is applied in the preparation method of peptides, chemical instruments and methods, peptides, etc., can solve the problems of high production cost, low extraction rate, and long enzymatic hydrolysis time, and achieve enhanced functional activity, Good taste, anti-tumor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The present invention is a subcritical water-assisted enzymatic hydrolysis method for extracting abalone protein peptides, comprising the following steps:

[0029] (1) Subcritical water treatment: 0.4 kg of abalone viscera and 1.2 L of pure water were added to the high-temperature reactor, and the temperature and pressure of the reactor were rapidly increased to 120°C and 7.0 MPa, kept at the pressure for 60 min, cooled to room temperature and released. Press, filter with gauze to obtain protein extract and filter residue;

[0030] (2) Enzymatic hydrolysis: Add 1.0 g of papain and 0.2 g of pectinase to about 1.2 L of protein extract obtained in step (1), and perform an enzymatic hydrolysis reaction for 1 h; the enzymatic hydrolysis conditions of the compound enzyme are pH 5.0 and temperature 50°C.

[0031] (3) Separation, concentration and spray drying: Add 6 g of activated carbon to the protein hydrolyzate obtained in step (2), keep it warm at 50°C for 60 minutes, then...

Embodiment 2

[0034] The present invention is a subcritical water-assisted enzymatic hydrolysis method for extracting abalone protein peptides, comprising the following steps:

[0035] (1) Subcritical water treatment: 0.3 kg of abalone viscera and 1.2 L of pure water were added to the high-temperature reactor, and the temperature and pressure of the reactor were rapidly increased to 140 °C and 4.0 MPa. Press, filter with gauze to obtain protein extract and filter residue;

[0036] (2) Enzymolysis: Add 4.5g flavor protease and 1.5g pectinase to about 1.2L of protein extract obtained in step (1), and perform enzymatic hydrolysis for 3 hours; the enzymatic hydrolysis conditions of the compound enzyme are pH 7.0 and temperature 45°C.

[0037](3) Separation, concentration and spray-drying: add 12 g of activated carbon to the protein hydrolyzate obtained in step (2), incubate at 45°C for 15 minutes, then use a disc centrifuge to remove the activated carbon; cool to room temperature, confirm the p...

Embodiment 3

[0040] The present invention is a subcritical water-assisted enzymatic hydrolysis method for extracting abalone protein peptides, comprising the following steps:

[0041] (1) Subcritical water treatment: 0.3 kg of abalone viscera and 1.5 L of pure water were added to the high-temperature reactor, and the temperature and pressure of the reactor were rapidly increased to 160 °C and 1.0 MPa. Press, filter with gauze to obtain protein extract and filter residue;

[0042] (2) Enzymolysis: Add 3.2g of bromelain and 0.8g of pectinase to about 1.4L of protein extract obtained in step (1), and carry out the enzymatic hydrolysis reaction for 2 hours; the enzymatic hydrolysis conditions of the compound enzyme are pH 6.0 and temperature 40°C.

[0043] (3) Separation, concentration and spray-drying: add 28 g of activated carbon to the protein hydrolyzate obtained in step (2), incubate at 40°C for 30 minutes, then use a disc centrifuge to remove the activated carbon; cool to room temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com