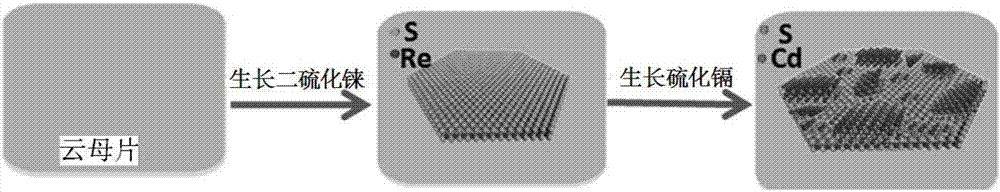

Preparation of rhenium sulfide and cadmium sulfide/rhenium sulfide composite material

A composite material, rhenium sulfide technology, applied in rhenium compounds, inorganic chemistry, chemical instruments and methods, etc., can solve the problems of poor size and thickness control, poor film lattice quality, weak interlayer force, etc., to achieve photoresponse efficiency and external quantum efficiency improvement, excellent optoelectronic properties, and the effect of large application potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

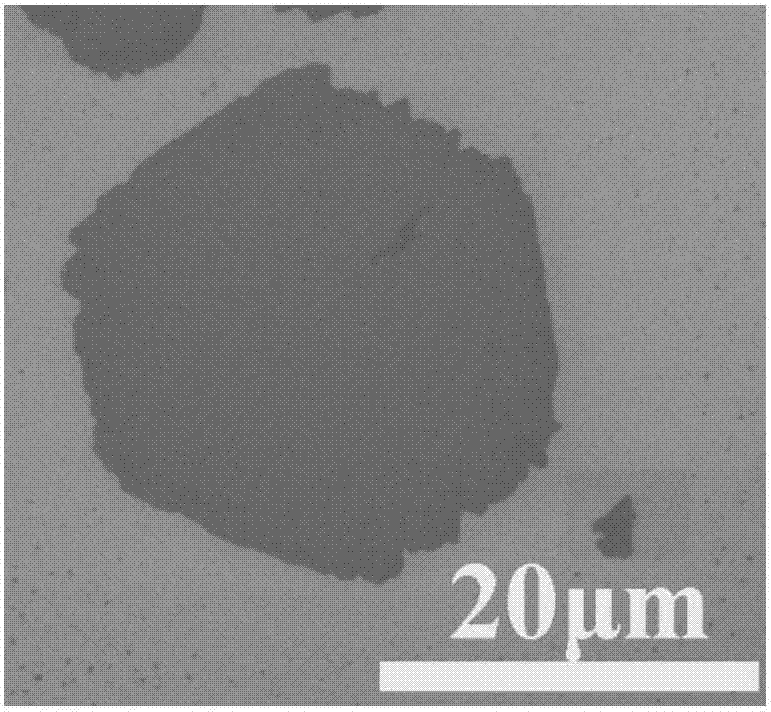

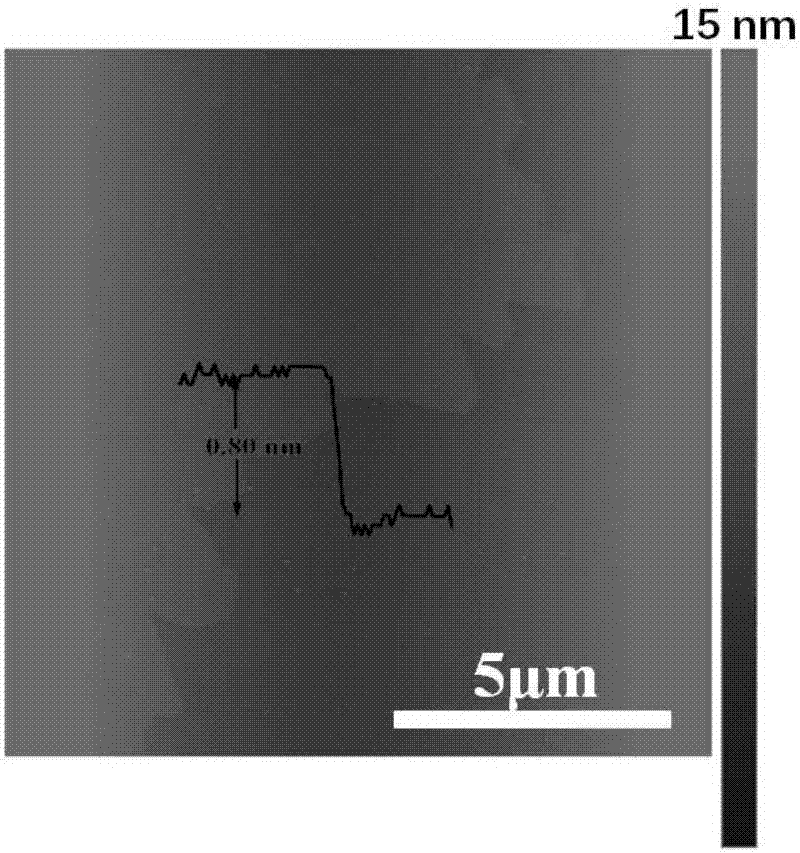

[0059] Embodiment 1 Preparation of rhenium sulfide

[0060] 5 mg of rhenium trioxide with a purity of 99.9% is evenly distributed in the graphite boat, and then the freshly stripped mica sheet is buckled upside down on the graphite boat, and the graphite boat is placed in the center of the heating zone of the single temperature zone tube furnace; 300 mg Sulfur powder with a purity of 99.9995% is put into the first quartz boat and pushed to the inlet end of the single temperature zone tube furnace.

[0061] Pass 300 sccm argon (Ar) into the tube furnace to clean the quartz tube (ie tube furnace) for 30 minutes to discharge the air in the quartz tube; then adjust the flow rate of argon to 80 sccm and continue feeding.

[0062] Set the heating program of the tube furnace so that the central temperature of the heating zone of the tube furnace (where the graphite boat is located) rises to 750°C within 20 minutes; , the flow rate of argon gas is 80 sccm, and the feeding time is 10 ...

Embodiment 2

[0074] Embodiment 2 Preparation of rhenium sulfide

[0075] 5 mg of rhenium trioxide with a purity of 99.9% is evenly distributed in the graphite boat, and then the freshly stripped mica sheet is buckled upside down on the graphite boat, and the graphite boat is placed in the center of the heating zone of the single temperature zone tube furnace; 500 mg Sulfur powder with a purity of 99.9995% is put into the first quartz boat and pushed to the inlet end of the single temperature zone tube furnace.

[0076] Pass 500 sccm argon (Ar) into the tube furnace to clean the quartz tube (i.e. the tube furnace) for 30 minutes to discharge the air in the quartz tube; then adjust the flow rate of argon to 100 sccm and continue feeding.

[0077]Set the heating program of the tube furnace so that the central temperature of the heating zone of the tube furnace (where the graphite boat is located) rises to 800°C within 30 minutes; , the flow rate of argon gas is 90 sccm, and the feeding time ...

Embodiment 3

[0080] Example 3 CdS / ReS 2 Preparation of composite materials

[0081] (1) Distribute 5 mg of rhenium trioxide with a purity of 99.9% evenly in the graphite boat, then place the freshly stripped mica sheet upside down on the graphite boat, and place the graphite boat in the center of the heating zone of the single-temperature zone tube furnace ; Put 300mg of sulfur powder with a purity of 99.9995% into the first quartz boat and push it to the inlet of the single-temperature zone tube furnace. Pass 300 sccm argon (Ar) into the tube furnace to clean the quartz tube (ie tube furnace) for 30 minutes to discharge the air in the quartz tube; then adjust the flow rate of argon to 80 sccm and continue feeding. Set the heating program of the tube furnace so that the central temperature of the heating zone of the tube furnace (where the graphite boat is located) rises to 750°C within 20 minutes; , the flow rate of argon gas is 80 sccm, and the feeding time is 10 min. When the central...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com