Automobile water-assisted engine

A technology for vehicles and motives, which is applied in the direction of engine components, combustion engines, machines/engines, etc., can solve the problems of different engine working conditions, engine working conditions, and difficulty in achieving fuel economy, and avoid the emission of toxic and harmful substances. Fast, Simple Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

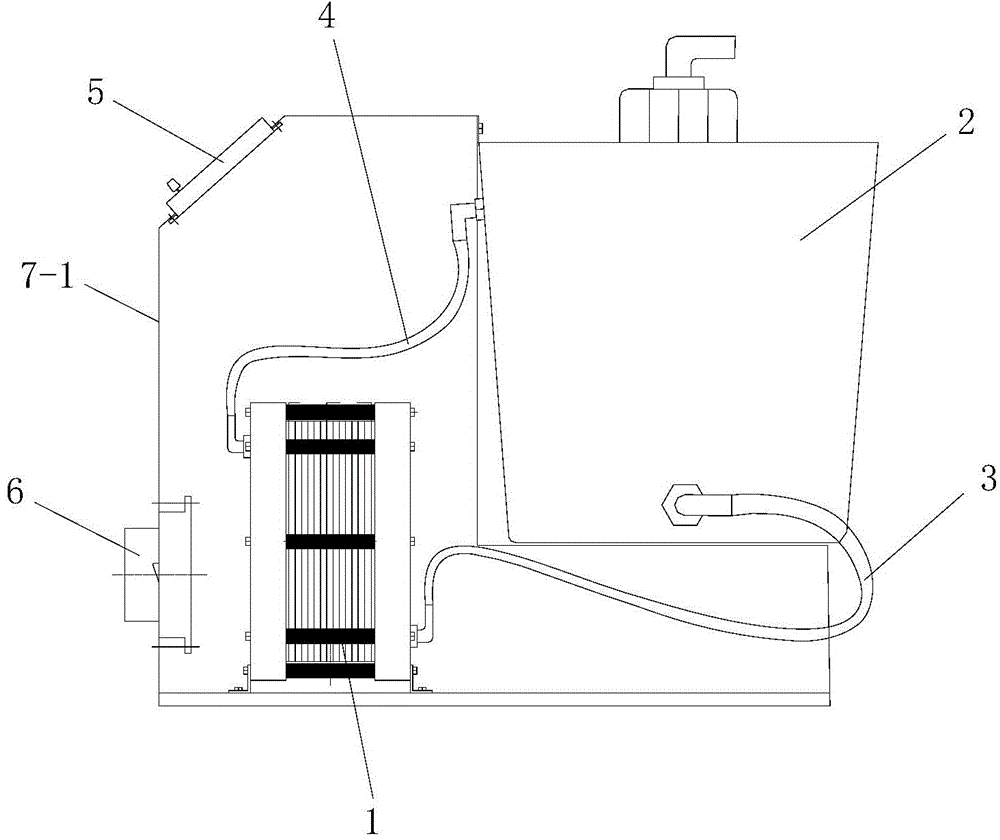

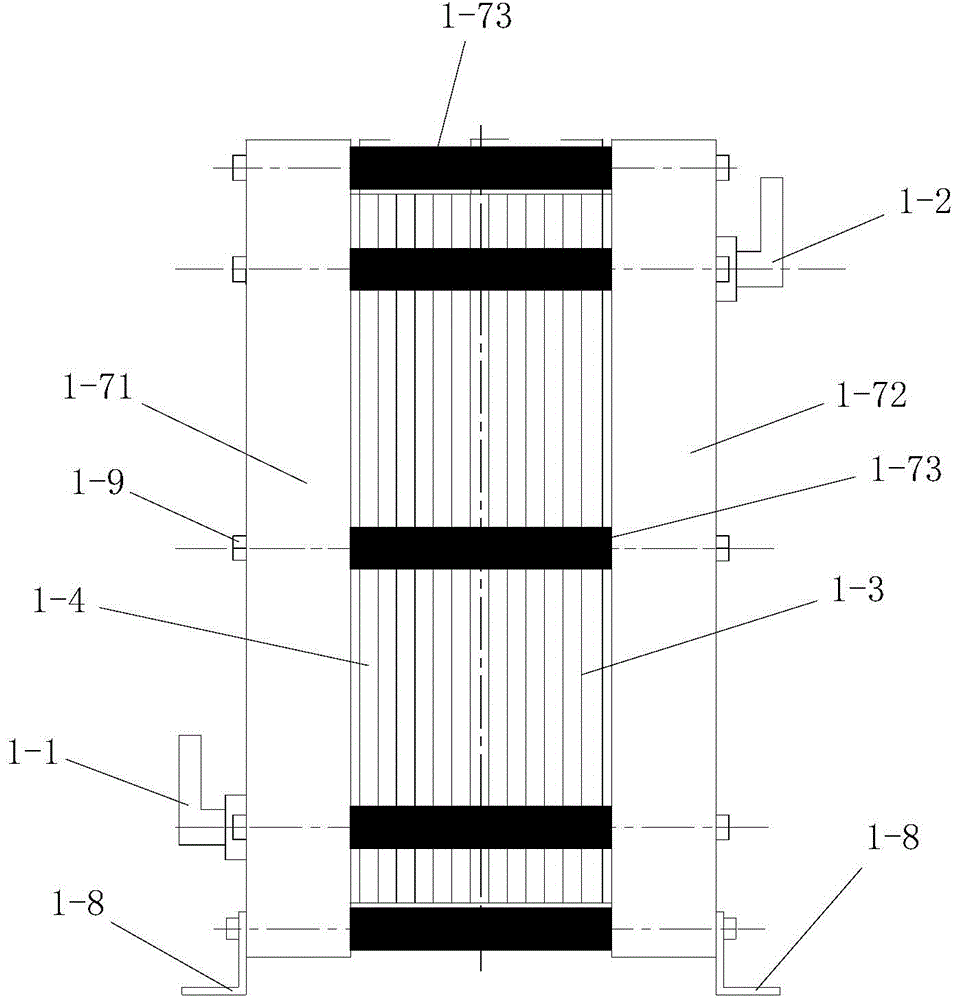

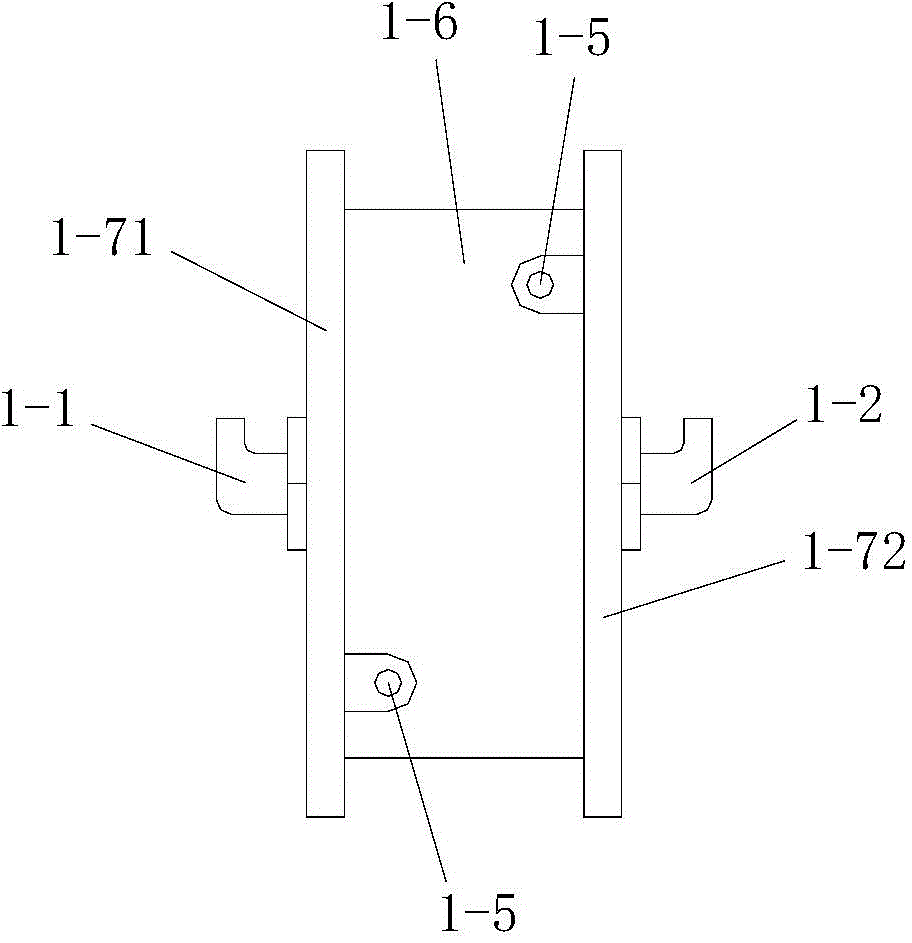

[0059] Such as figure 1 As shown, the present invention includes a water electrolysis reactor 1 for generating hydrogen and oxygen and a kettle 2 for delivering collected hydrogen and oxygen to a vehicle engine, and the water electrolysis reactor 1 has a reactor water inlet and the reactor gas outlet, the kettle 2 is provided with a kettle air inlet, a kettle gas outlet, a kettle water inlet and a kettle water outlet, and the kettle water outlet and the reactor water inlet are connected through a water delivery pipe 3, so The air outlet of the reactor is connected with the air inlet of the kettle through an air pipe 4 .

[0060] The flow rate of the mixed gas delivered by the kettle 2 to the vehicle engine is 0.7 slpm (ie, standard liter per minute flow value) to 2.60 slpm, and the mixed gas is composed of hydrogen and oxygen. In actual use, the hydrogen and oxygen generated by the water electrolysis reactor 1 are collected through the kettle 2, and the collected hydrogen and...

Embodiment 2

[0132] In this embodiment, the difference from Example 1 is that the number of the water electrolysis reactor 1 is two, and the reactor water inlets of the two water electrolysis reactors 1 are connected to the kettle 2 through the water delivery pipe 3. The water outlets of the kettles are connected, and the reactor gas outlets of the two water electrolysis reactors 1 are all connected to the kettle air inlets of the kettle 2 through the air pipe 4 .

[0133] In this embodiment, the two water electrolysis reactors 1 are installed side by side on the inner bottom of the cubic shell 7-2, and the kettle 2 is arranged above the two water electrolysis reactors 1 and is located in the cubic shell 7-2. A control panel 5 and a circuit board housing 6 connected to the PWM controller are installed on the outer sidewall of the cubic housing 7-2.

[0134] In this embodiment, the DC power supply is a storage battery on the vehicle, and the power supply voltage of the storage battery is 12...

Embodiment 3

[0138] Such as Figure 8 , Figure 9 and Figure 10 As shown, in this embodiment, the difference from Example 1 is that the number of the water electrolysis reactors 1 is four, and the reactor water inlets of the four water electrolysis reactors 1 are all passed through the water delivery pipe 3 It is connected with the kettle water outlet of the kettle 2, and the reactor air outlets of the four water electrolysis reactors 1 are all connected with the kettle air inlet of the kettle 2 through the air pipe 4.

[0139] In this embodiment, the kettle 2 and the four water electrolysis reactors 1 are installed in a cuboid housing 7-4, and the cuboid housing 7-4 includes a mounting plate 7-3 and a cover mounted on the mounting plate 7-3 on the upper shell, four of the water electrolysis reactors 1 are installed on the installation plate 7-3, the installation plate 7-3 is provided with a kettle bracket 8 for the installation of the kettle 2, and the four water electrolysis reactors ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com