Well pattern and method for improving fire flooding effect of thick-layer heavy oil reservoir

A technology for heavy oil reservoirs and well patterns, applied in earthwork drilling, wellbore/well components, production fluids, etc., can solve the interference of two well rows, serious oil wall damage, lack of accurate judgment of the front edge of the fire line, etc. To achieve the effect of solving the serious gas channeling and improving the effect of fire flooding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

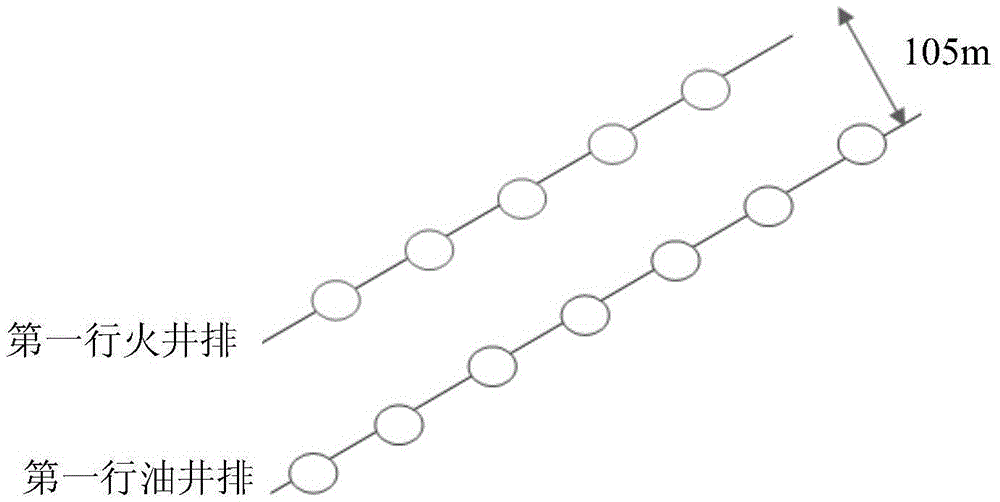

[0059] This embodiment provides a well pattern for improving the fire flooding effect of thick heavy oil reservoirs. The structure layout of the well pattern is as follows figure 2 Shown.

[0060] In the above-mentioned well pattern, a row of fire wells are linearly deployed on the top of the monoclinic structure at block 3,618. There are 6 fire wells in the fire wells, and the horizontal well spacing between two adjacent fire wells is 75m (or 50m). ;

[0061] In the downward direction of the first row of fire well rows, a row of oil well rows (7 oil wells) parallel to it is deployed; the plane row distance between the oil well row and the fire well row is 105m, and there are two adjacent oil wells in the oil well row. The plane well distance between is 75-105m;

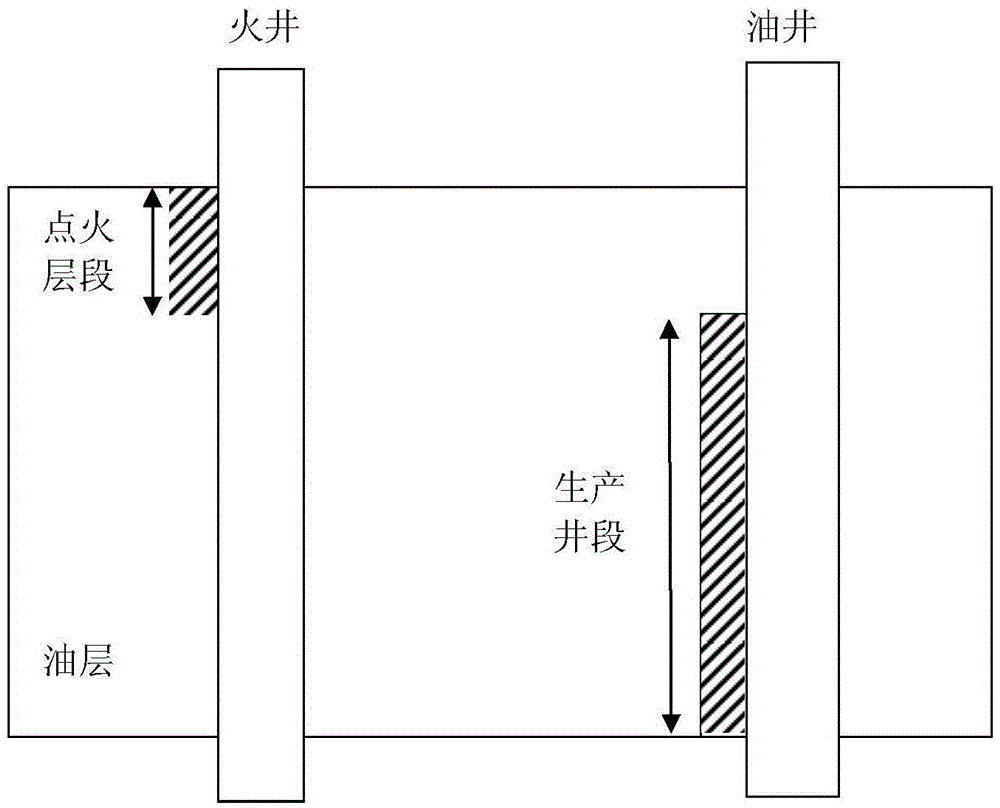

[0062] The ignition interval in the fire well is the area down the top of the oil layer. The thickness of this area accounts for 1 / 4 of the thickness of the entire oil layer (such as image 3 Shown);

[0063] The productio...

Embodiment 2

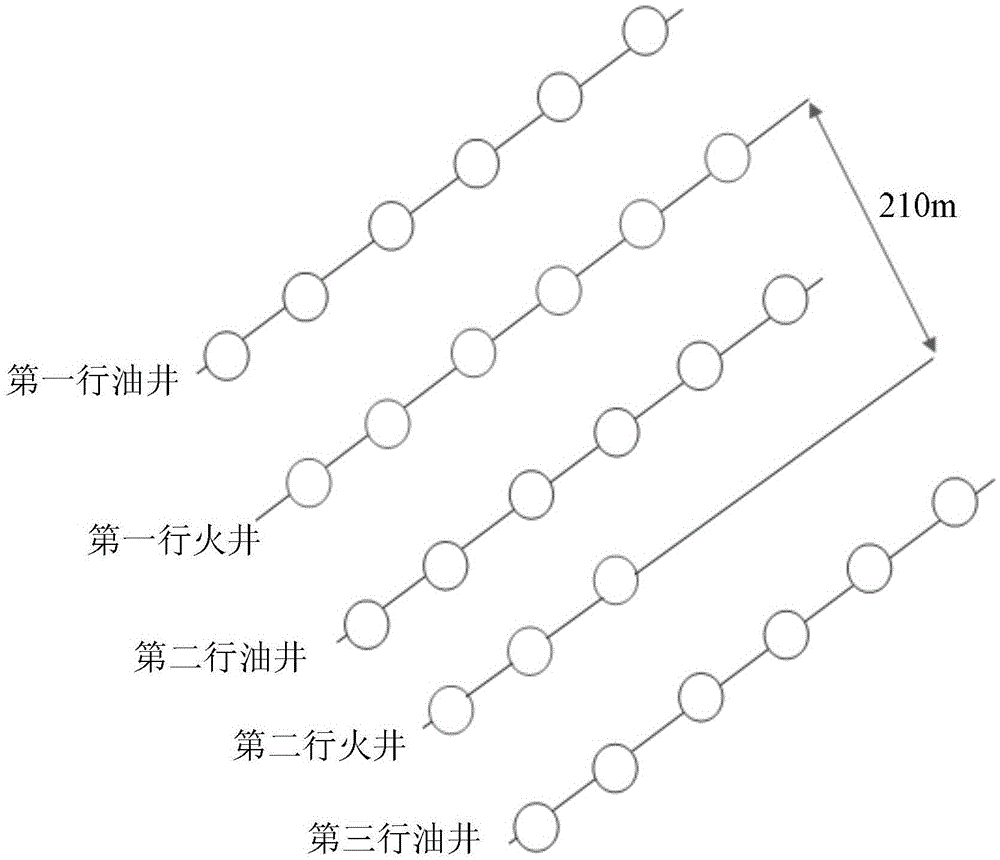

[0065] This embodiment provides a well pattern for improving the fire flooding effect of thick heavy oil reservoirs. The well pattern (such as Figure 4 (Shown) is obtained after rectifying the well pattern provided in the above comparative example 1.

[0066] 1) Shut in or plug the first row of oil wells located in the updip direction of the first row of fire wells (to suppress gas production in the updip direction);

[0067] 2) Stop gas injection to the second row of fire wells located in the downward dipping direction of the first row (to prevent interference with the fire discharge effect of the first row of fire wells in the upward dipping direction);

[0068] After such adjustments Figure 4 As shown, there is only one row of fire well rows in the well pattern, which are located in the high part of the monoclinic structure. The downward dip direction of the above fire well rows is two rows of oil well rows (labeled as the first row of oil well rows and the second row of oil we...

Embodiment 3

[0070] This embodiment provides a method for improving the fire flooding effect of thick heavy oil reservoirs. The method is carried out by using the well pattern provided in the above embodiment 1, and includes the following steps:

[0071] 1) In order to ensure that the fire drive is carried out in the high-temperature combustion mode with high displacement efficiency, it is necessary to ensure that the front of the fire drive maintains the advancing speed under high temperature combustion. The speed is taken as 8cm / d on site; The advancing speed of the edge estimates the reasonable gas injection speed of the fire well. In this example, a long tube experiment was carried out on the Gaosheng Oilfield, and the results showed that the combustion of 1m 3 Oil layer needs 300m 3 Air; according to this result, we set burning 1m 3 Oil layer needs 300m 3 For air, the advancing speed of the combustion front is 8cm / d, the thickness of the fuel layer is 20m, and the combustion sweep rate is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com