Evaporation device

A technology of evaporation and evaporation source, which is applied in vacuum evaporation plating, sputtering plating, ion implantation plating, etc. It can solve the problems of high mechanical structure precision, small size, damage to the smooth surface of the inner wall, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Exemplary embodiments of the present invention are described in detail below. The exemplary embodiments described below and illustrated in the accompanying drawings are intended to teach the principles of the invention and enable those skilled in the art to implement and use the invention in a number of different environments and for a number of different applications.

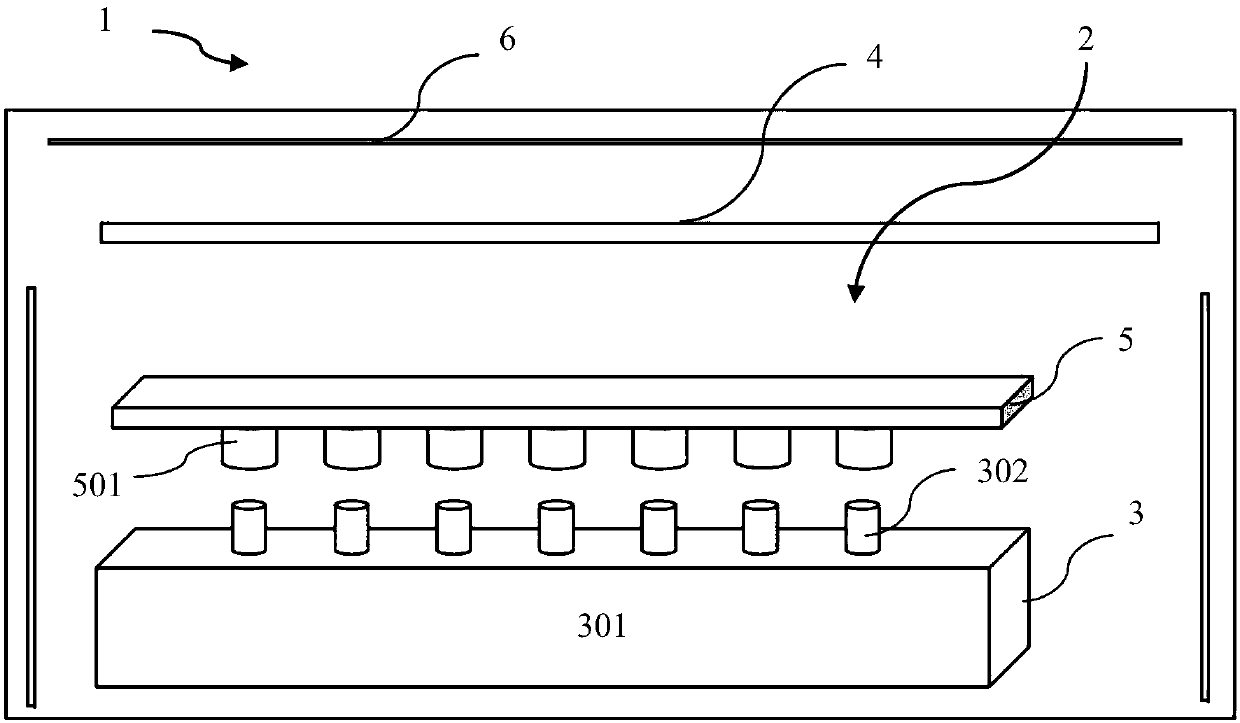

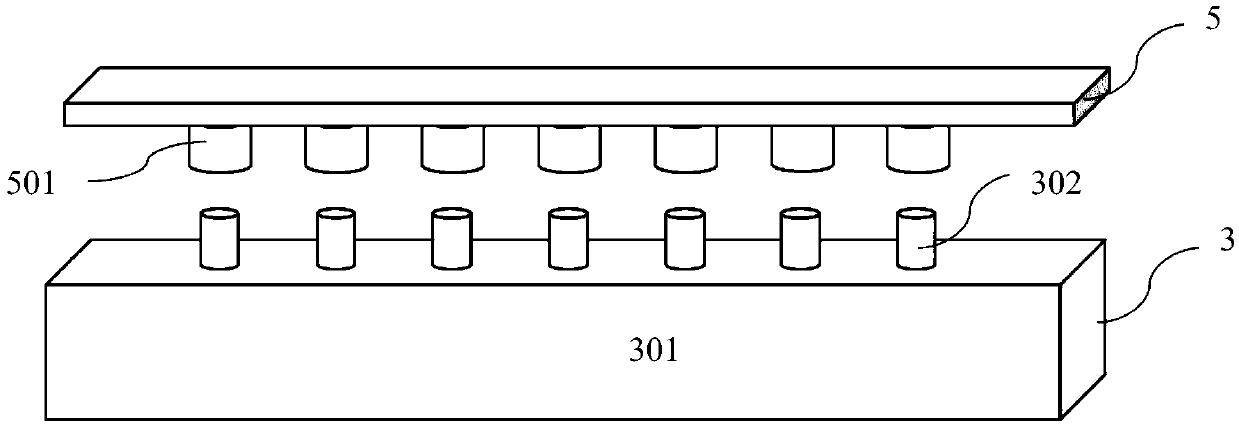

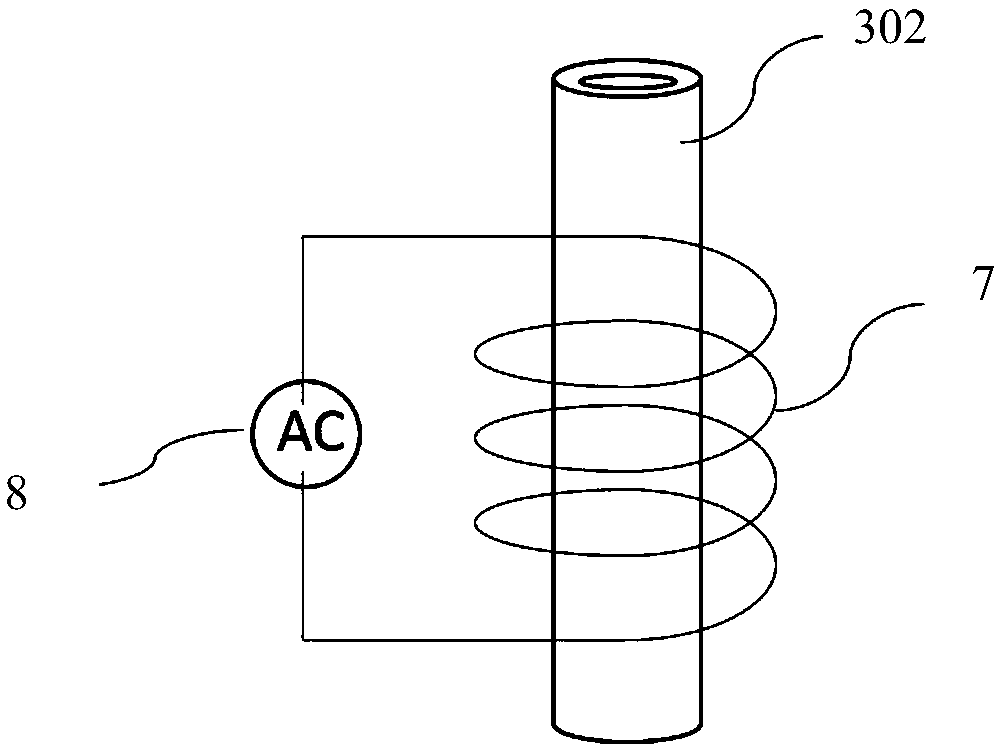

[0027] figure 1 An embodiment of a vapor deposition device 1 according to the invention is shown. As can be seen from the figure, the evaporation device 1 includes an evaporation source 3, the evaporation source 3 has a housing and a plurality of evaporation nozzles 302 arranged on the top of the housing; and an electromagnetic induction heater, which is used for The evaporation nozzle is heated, wherein the electromagnetic induction heater is arranged so that the relative distance between it and the evaporation nozzle 302 can be adjusted. This electromagnetic induction heater adopts the principle of e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com