Long-acting high-permeability pervious concrete

A permeable concrete and high-permeability technology, applied in the field of permeable concrete and concrete, can solve the problems of inability to ensure the continuity of water permeability, loss of water seepage, peeling of gravel, etc., and achieve the benefits of popularization, reduction of hole plugging, and increase of porosity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] Preparation of corrosion inhibitor:

[0025] Choose 5-8mm granular alum and 5-8mm silicon-phosphorus crystals to mix evenly in a ratio of 1:2, and spray the mixture formed by VAE emulsion + cement + water in a ratio of 2:1:7 on the surface of the particles to make the particles A thin protective film is formed on the surface to obtain a water corrosion inhibitor that does not deliquesce or weather during storage and is beneficial to improve the interface effect, and is ready for use.

Embodiment

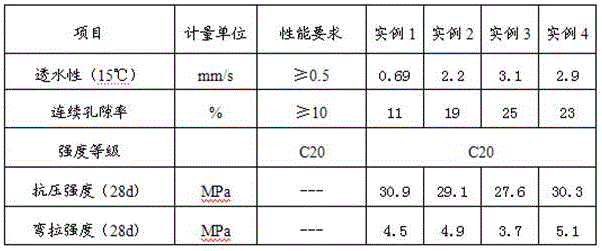

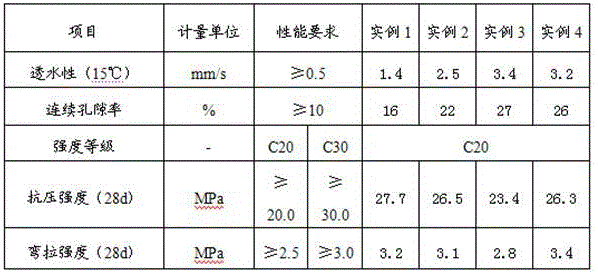

[0027] 1. Formula (unit: Kg)

[0028]

[0029] 2. Preparation

[0030] According to the above formula, mix the raw materials evenly, add 35% water of the total amount of concrete, and use a forced mixer to mix on site to obtain permeable concrete.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com