Preparation method of selective water plugging agent

A water shutoff agent, selective technology, applied in the field of preparation of selective water shutoff agent, can solve the problems of poor permeability, water shutoff performance can not be further improved, to achieve long-term selective permeability, improve water shutoff Effect, effect of binding force enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

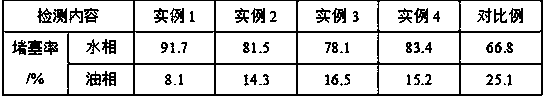

Examples

example 1

[0021]Mix graphene oxide and N,N-dimethylformamide in a beaker at a mass ratio of 1:400, and ultrasonically disperse at a frequency of 55 kHz for 4 hours to obtain a graphene oxide dispersion. Mix it with organic amine in the flask at a mass ratio of 25:1, and add dicyclohexylcarboimide that is 0.05 times the mass of the graphene oxide dispersion into the flask, and ultrasonically disperse it at a frequency of 55kHz for 10 minutes. After stirring and reacting for 45 hours under the conditions of 130°C and 350r / min, the material in the flask was allowed to stand at room temperature for 30 hours, and then the supernatant liquid was removed to obtain a pre-modified graphene oxide mixture, which was filtered to obtain a pre-modified graphene oxide mixture. To obtain a filter cake, the filter cake was first washed with absolute ethanol for 6 times, then washed with water for 5 times, and dried for 3 hours at a temperature of 75°C to obtain pre-modified graphene oxide; pre-modified g...

example 2

[0023] Mix graphene oxide and organic solvent in a three-necked flask at a mass ratio of 1:30, and add organosilicon 6 times the mass of graphene oxide and water 0.3 times the mass of graphene oxide to the three-necked flask at a temperature of 35°C. After stirring and reacting for 50 hours at a rotating speed of 400r / min, the materials in the three-necked flask were allowed to stand at room temperature for 10 minutes, and then filtered to obtain a modified graphene oxide blank. The modified graphene oxide blank was sequentially washed with anhydrous toluene, n-hexane, After washing once each with ethanol, acetone, ethanol and water, and at a temperature of 70°C for 3 hours, modified graphene oxide was obtained; acrylamide and methyl silicate were mixed at a mass ratio of 2.0:1.0, and added to acrylic Add 2-acrylamide-2-methylpropanesulfonic acid with 0.7 times the quality of acrylamide to the mixture of amide and methyl silicic acid, dimethyl diallyl ammonium chloride with 0.2...

example 3

[0025] Mix acrylamide and methyl silicic acid at a mass ratio of 2.0:1.0, and add 2-acrylamide-2-methylpropanesulfonic acid and acrylamide 0.7 times the mass of acrylamide to the mixture of acrylamide and methyl silicic acid 0.25 times the mass of dimethyl diallyl ammonium chloride and 12 times the mass of acrylamide N,N-dimethylformamide were stirred and mixed for 30 minutes at a temperature of 40°C and a rotational speed of 400r / min. The pretreatment mixed solution is obtained; the pretreatment mixed solution and the silane coupling agent are mixed in the reactor at a mass ratio of 100:1, and graphene oxide 0.09 times the mass of the pretreated mixed solution is added to the reactor, and the pretreated mixed solution is Epoxidized soybean oil with a mass of 0.02 times and a catalyst with a mass of 0.009 times the pretreatment mixed solution were stirred and mixed for 30 minutes at a temperature of 40°C and a rotational speed of 400r / min, and then 0.03 times the mass of the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com