Double-layer coupling beam hole opening formwork system and construction method of double-layer coupling beam hole opening formwork system applied to double-layer coupling beam

A connecting beam and double-layer technology, which is applied in the field of formwork/formwork/work frame, preparation of building components on site, construction, etc., can solve the problem of waste of resources that cannot be reused, poor stability of extruded polystyrene boards, and poor quality of concrete Satisfy and other problems, to achieve the effect of good appearance and perception quality, saving construction period, and not easy to expand the mold phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

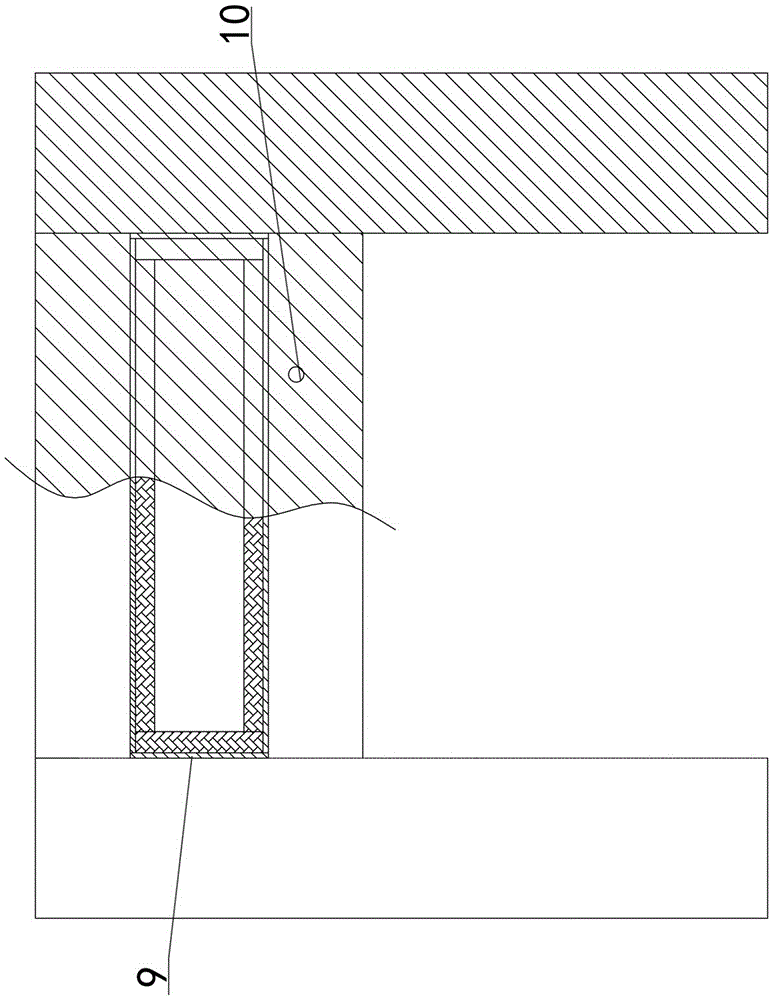

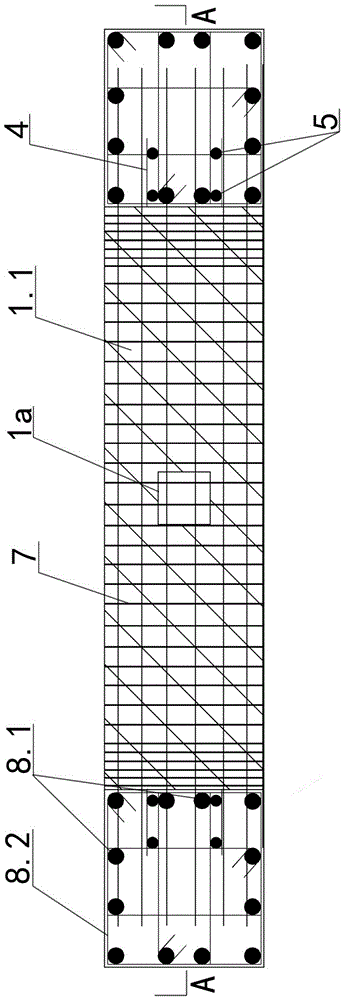

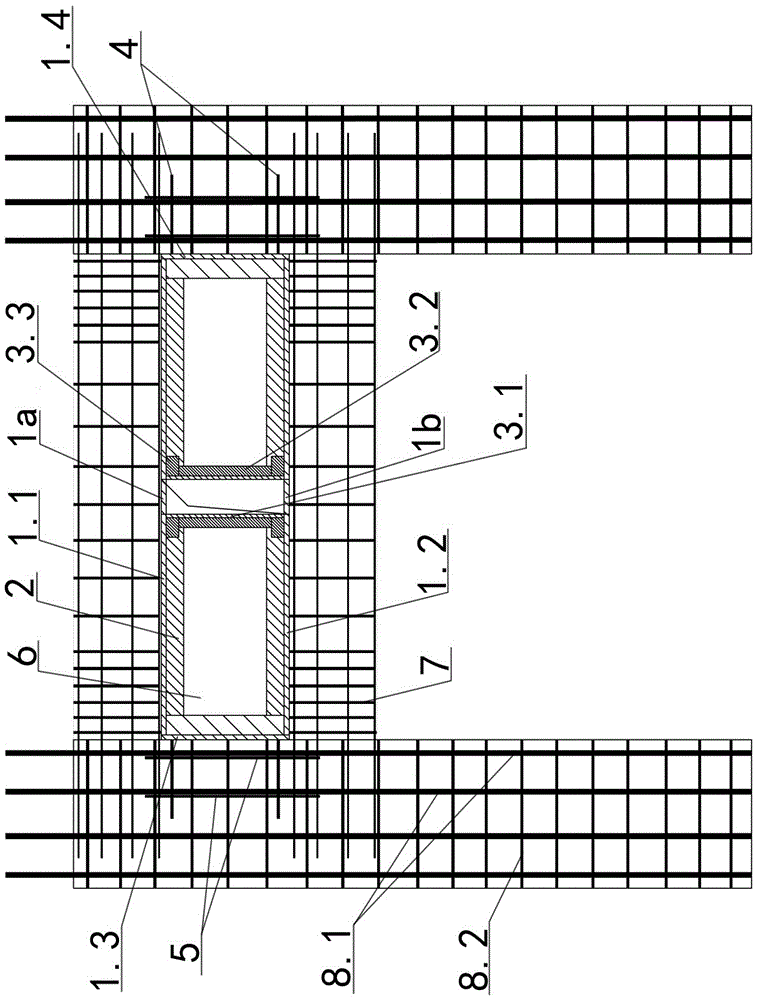

[0039] Embodiment one sees Figure 2-4 As shown, the general lengths of double-layer coupling beams are: 1800mm, 2400mm, 3200mm, 3300mm, etc. The length of the opening of the double-layer coupling beam that needs formwork support is less than 3m. This double-layer coupling beam opening formwork system includes an opening formwork and a formwork support. The opening formwork includes a frame body 1 and a frame back flute 2. The frame The body support is arranged in the opening of the double-layer coupling beam and adapts to the size of the opening of the double-layer coupling beam, at least including the upper side plate 1.1, the lower side plate 1.2, the left side plate 1.3 and the right side plate 1.4, and the opening formwork also includes At least one lower ash vibrating cylinder 3 vertically connected to the upper side plate and the lower side plate is provided inside the frame body.

[0040] There is an upper opening 1a on the upper side plate 1.1, and a corresponding lo...

Embodiment 2

[0044] Embodiment two see Figure 6-7As shown, the difference from Example 1 is that the length of the double-layer connecting beam hole that needs formwork is greater than 3m. In order to ensure the appearance and structural quality after the concrete pouring and formwork removal, the lower ash vibrating cylinder 3 is at least set Two, three are provided in this embodiment, the spacing is 0.75m, and they are arranged in a straight line along the length direction of the double-layer connecting beam.

[0045] The frame body of the present invention can also form a box body after adding a front side plate and a rear side plate.

[0046] The construction steps of the above two double-layer coupling beam construction methods using the double-layer coupling beam opening formwork system are as follows:

[0047] Step 1, binding the steel bars 7 of the double-layer connecting beam and the column bars 8 of the structural columns on both sides of the double-layer connecting beam.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com