Grouting and sealing waterproof shield segment structure and construction method thereof

A technology of shield segment and construction method, which is applied to earth-moving drilling, wellbore lining, tunnel lining, etc., can solve the problems of difficult maintenance, damage to segment structure, and high cost, so as to reduce engineering costs and operation and maintenance costs. , reduce repairs, economical and safe effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

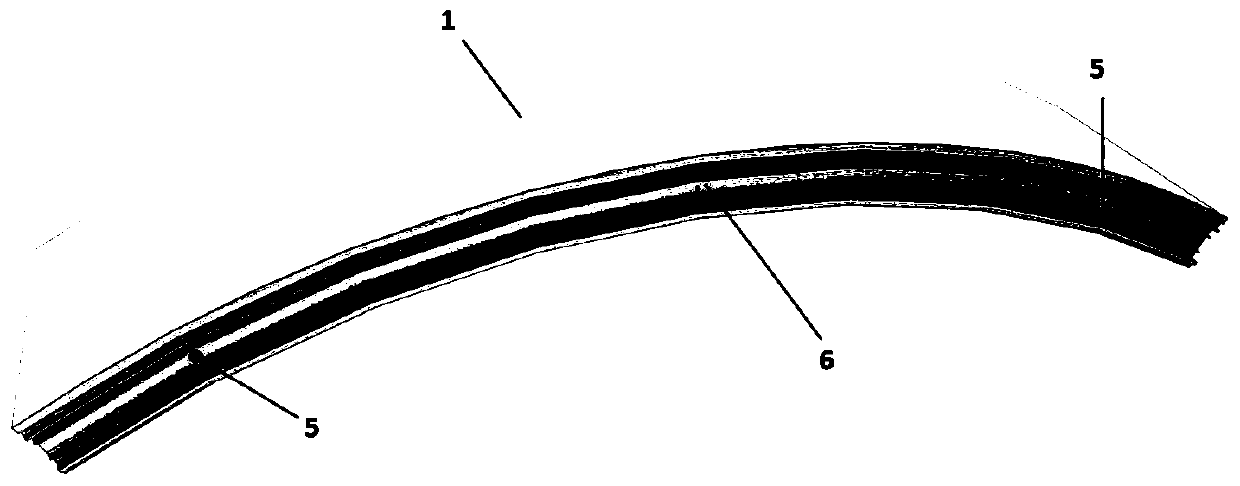

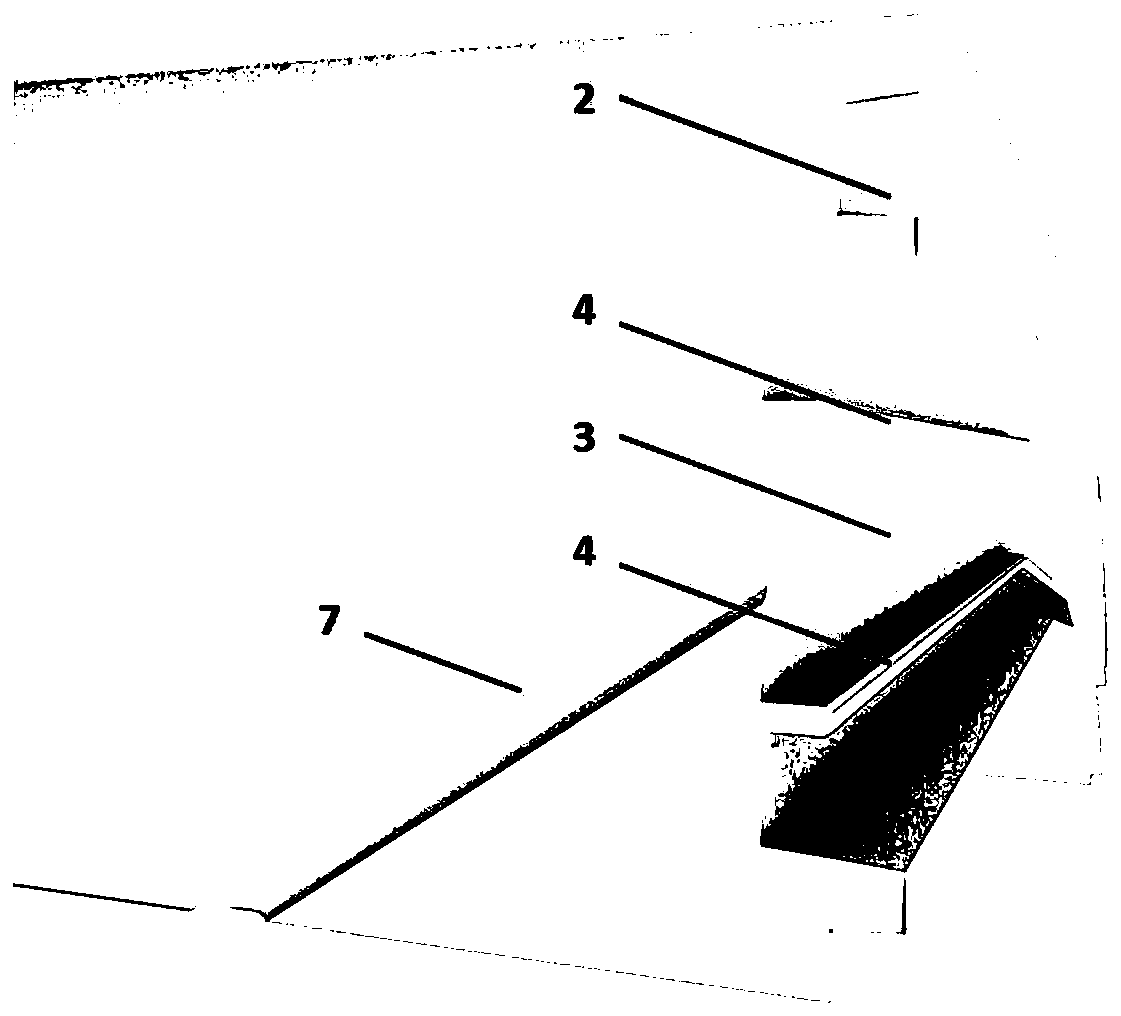

[0027] The thickness of a shield segment is 300mm, and the structural layout of the four sides of the segment is as follows: figure 1 shown. The rubber waterstop 2 is pasted at a distance of 30 mm from the outer surface of the segment, with a width of 20 mm and a thickness of 10 mm. The grouting waterstop groove 3 is 30mm inside the rubber waterstop strip 2, 40mm away from the inner surface of the segment 1, with a width of 180mm and a depth of 20mm. Four projections 4 are arranged radially in the grouting waterstop 3, the projection width is 20mm, and the projection height is 15mm. The small grouting hole 5 is set at the center of the grouting water stop groove 3 on each side of the segment, between the third and fourth protrusions 4 . The small grouting channel 7 is 45° to the side of the segment 1 and leads to the inner surface of the segment.

Embodiment 2

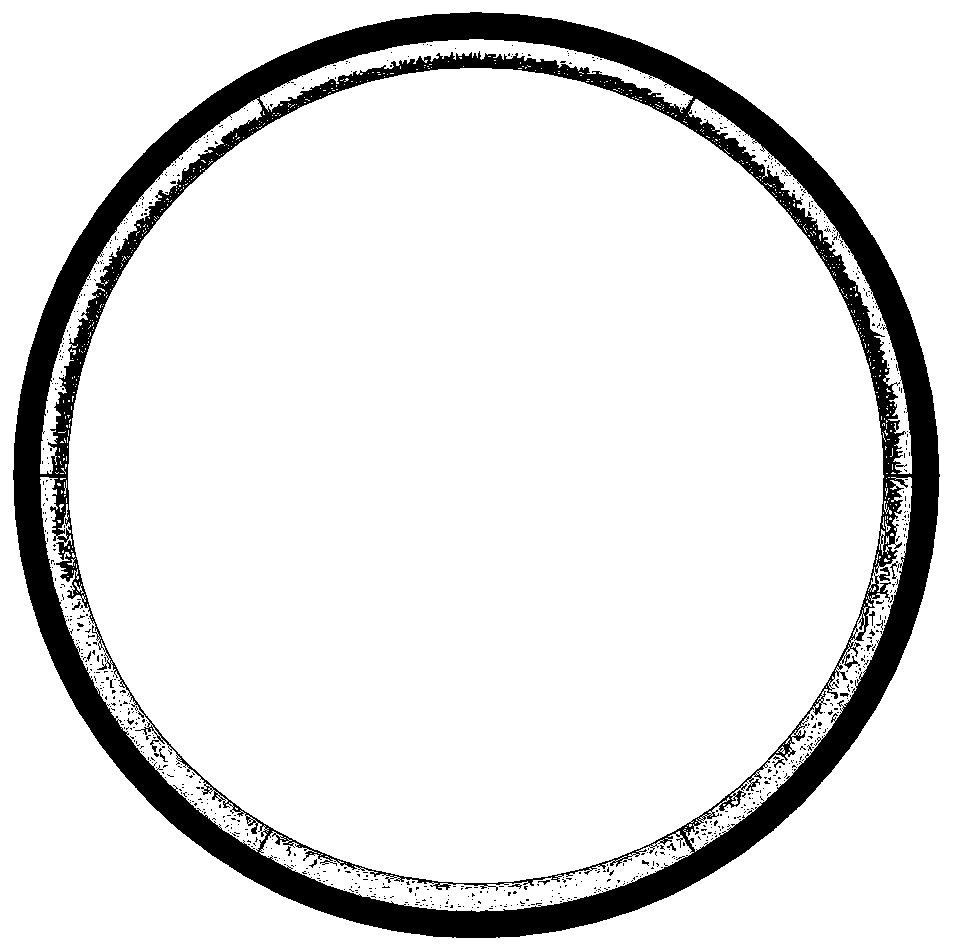

[0029] The thickness of a shield segment is 200mm, and the structural layout of the four sides of the segment is as follows: figure 1 shown. The rubber waterstop 2 is pasted at a distance of 25mm from the outer surface of the segment, with a width of 20mm and a thickness of 10mm. The grouting waterstop groove 3 is 20mm inside the rubber waterstop strip 2, 30mm away from the inner surface of the segment 1, with a width of 105mm and a depth of 20mm. Two projections 4 are arranged radially in the grouting waterstop 3, the width of the projections is 20mm, and the height of the projections is 15mm. The small grouting hole 5 is set at the center of the grouting water stop groove 3 on each side of the segment, between the two protrusions 4 . The small grouting channel 7 is 45° to the side of the segment 1 and leads to the inner surface of the segment. After the segment assembly is completed, such as image 3 As shown, through the grouting equipment, the grouting waterstop area i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com