Low-permeability increment ceramic coating diaphragm and preparation method thereof

A ceramic coating, low air permeability technology, applied in coatings, electrical components, structural parts, etc., can solve the problems affecting the battery cycle performance and rate performance, increase the air permeability of the ceramic film, and increase the internal resistance of the battery, etc., and achieve excellent air permeability. performance, reducing the air permeability increment, and reducing the effect of the internal resistance of the diaphragm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

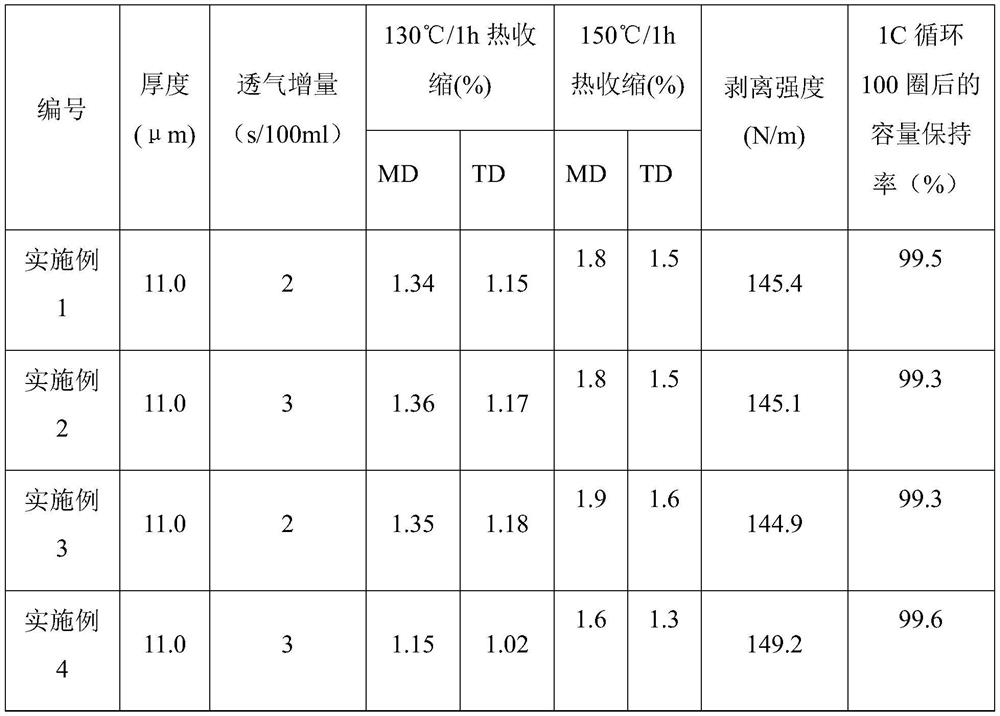

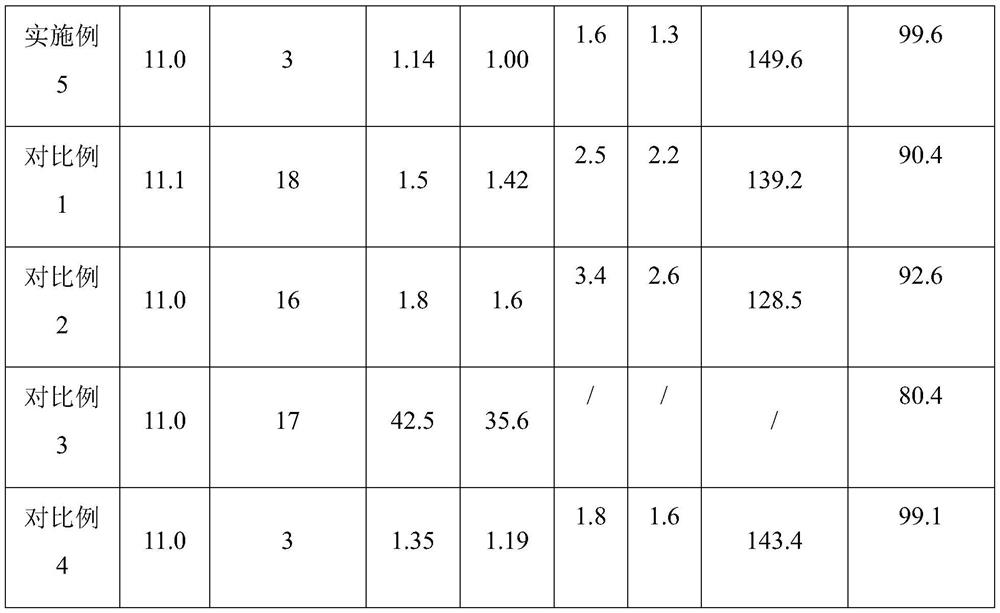

Examples

Embodiment 1

[0025] A preparation method of a low-gas-permeable-increment ceramic-coated diaphragm, characterized in that it comprises the following steps:

[0026] (1) Mix the water-resistant binder and the hydrolyzable binder, and stir for 30 minutes to obtain the binder; the water-resistant binder and the hydrolyzable binder are compounded in a mass ratio of 1:0.5. The water-resistant adhesive is an acrylic resin adhesive (GR506), and the hydrolyzable adhesive is a polyvinyl alcohol adhesive.

[0027] Take the dispersant and put it in ultrapure water, add the ceramic powder after stirring for 5 minutes, add the binder after stirring for 30 minutes, add the wetting agent after stirring for 1 hour, and stir again for 30 minutes to obtain the ceramic slurry; in terms of mass percentage, the dispersion 0.9% of agent, 40% of ceramic powder, 3.5% of binder, 0.35% of wetting agent, and the rest are ultrapure water.

[0028] (2) Coating the prepared ceramic slurry on both sides of the base fil...

Embodiment 2

[0031] A preparation method of a low-gas-permeable-increment ceramic-coated diaphragm, characterized in that it comprises the following steps:

[0032] (1) Mix the water-resistant binder and the hydrolyzable binder, and stir for 20 minutes to obtain the binder; the water-resistant binder and the hydrolyzable binder are compounded in a mass ratio of 1:0.3. The water-resistant adhesive is an acrylic resin adhesive (GR506), and the hydrolyzable adhesive is a polyvinyl alcohol adhesive.

[0033] Take the dispersant and put it in ultrapure water, add ceramic powder after stirring for 10 minutes, add binder after stirring for 25 minutes, add wetting agent after stirring for 1.5 hours, and stir again for 25 minutes to obtain ceramic slurry; in terms of mass percentage, The dispersant is 3%, the ceramic powder is 45%, the binder is 6.5%, the wetting agent is 0.55%, and the rest is ultrapure water.

[0034] (2) Coating the prepared ceramic slurry on both sides of the base film to form...

Embodiment 3

[0037] A preparation method of a low-gas-permeable-increment ceramic-coated diaphragm, characterized in that it comprises the following steps:

[0038] (1) Mix the water-resistant binder and the hydrolyzable binder, and stir for 30 minutes to obtain the binder; the water-resistant binder and the hydrolyzable binder are compounded in a mass ratio of 1:1. The water-resistant adhesive is an acrylic resin adhesive (GR506), and the hydrolyzable adhesive is a polyvinyl alcohol adhesive.

[0039] Take the dispersant and put it in ultrapure water, add the ceramic powder after stirring for 10 minutes, add the binder after stirring for 30 minutes, add the wetting agent after stirring for 1.5 hours, and stir again for 30 minutes to obtain the ceramic slurry; in terms of mass percentage, Dispersant 0.6%-, ceramic powder 30%, binder 2.5%, wetting agent 0.15%, and the rest is ultrapure water.

[0040] (2) Coating the prepared ceramic slurry on both sides of the base film to form a ceramic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com