Porous collaborative fracturing and extracting integrated gas extraction method

A technology of gas drainage and fracturing, which is applied in the field of multi-hole cooperative pressure and drainage integrated gas drainage, which can solve problems such as insufficient coal seam pressure relief, gas explosion, and complicated construction technology, so as to improve the permeability of coal seams and reduce plugging Function, the effect of simple construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

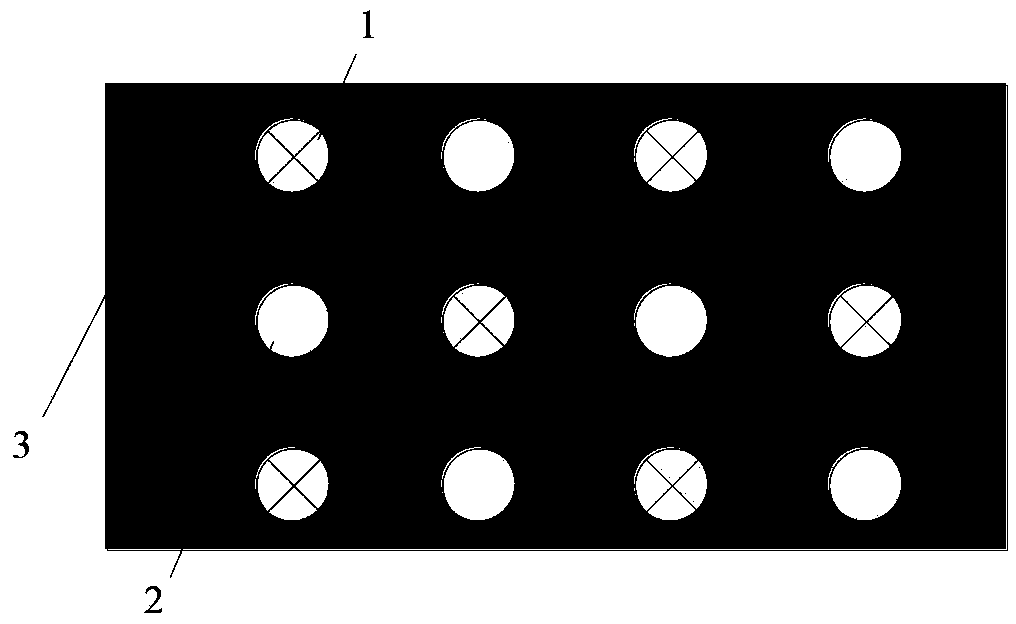

[0013] The multi-hole cooperative pressure-pumping integrated gas drainage method of the present invention: First, a plurality of fracturing holes 1 and gas drainage holes 2 are evenly and alternately constructed on the side of the roadway to the coal seam 3 according to the distance between rows and columns, such as figure 1 As shown, all boreholes have a diameter of 90-120mm and a length of 80-100m. Before drilling and sealing, feed seamless steel pipes into the fracturing holes as fracturing pipes, and feed PVC pipes into the gas drainage holes as gas drainage pipes. The diameter of the seamless steel pipe is 25mm, and the diameter of the PVC pipe is 50mm. Seal all the fracturing holes 1 according to the requirement that the minimum pressure that can withstand is 20MPa, and seal all the gas drainage holes 2 according to the conventional method; The PVC ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com