Stop treatment method for ink-jet recording apparatus

A technology of inkjet recording and processing method, applied in printing and other directions, can solve the problems of reduced suction efficiency, longer stop processing time, reduced liquid flow, etc., to achieve the effect of reducing the amount of solvent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

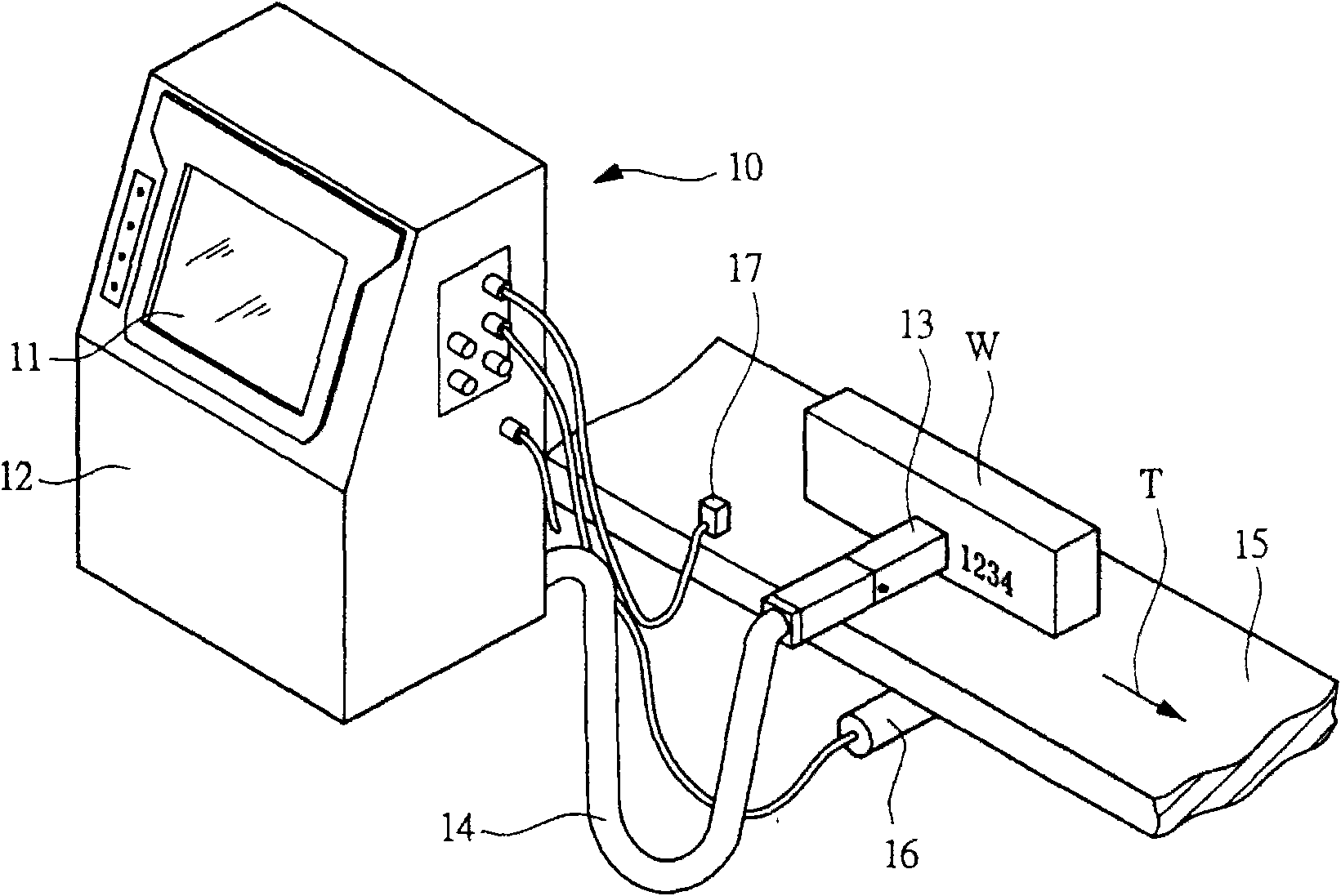

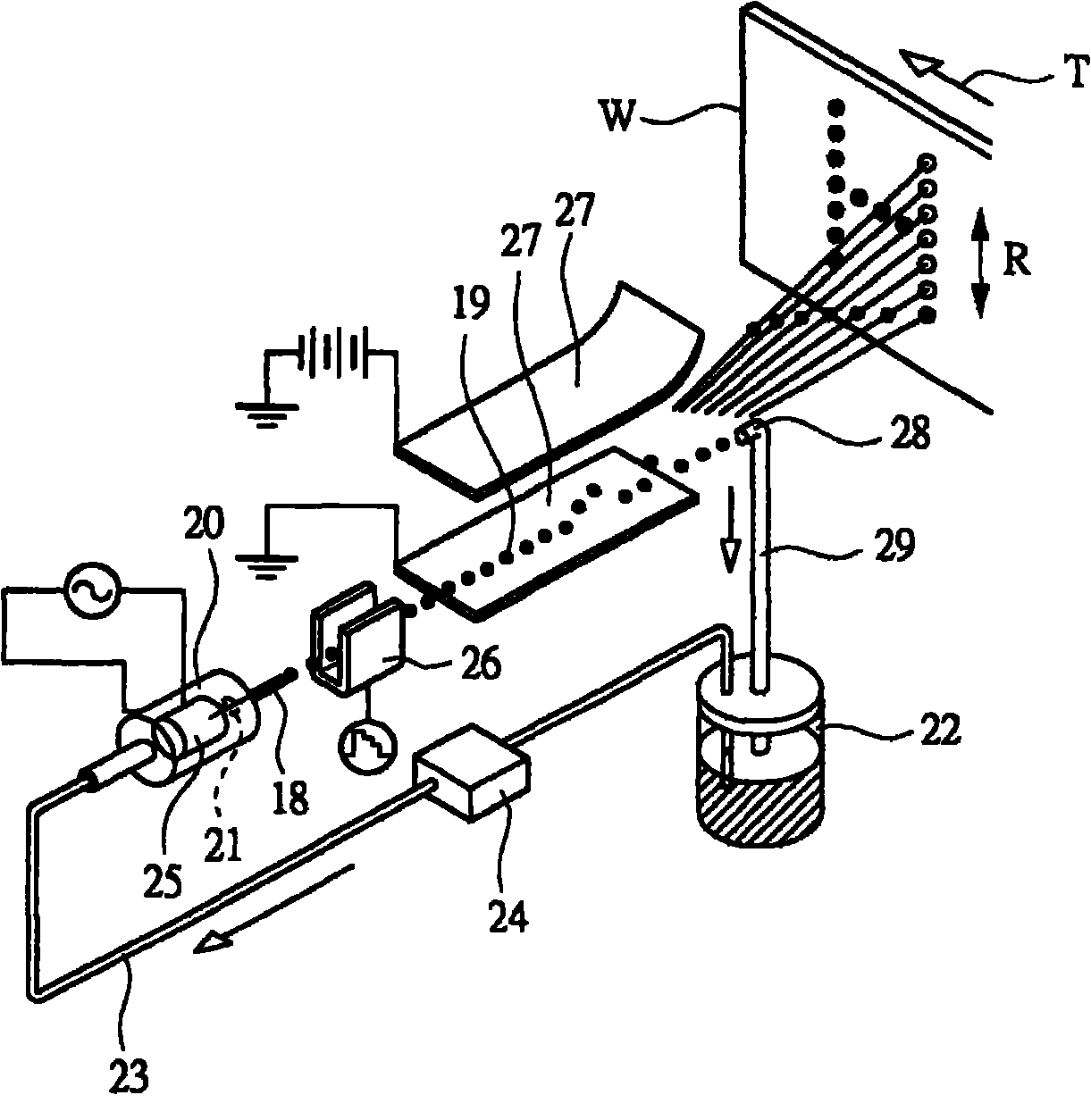

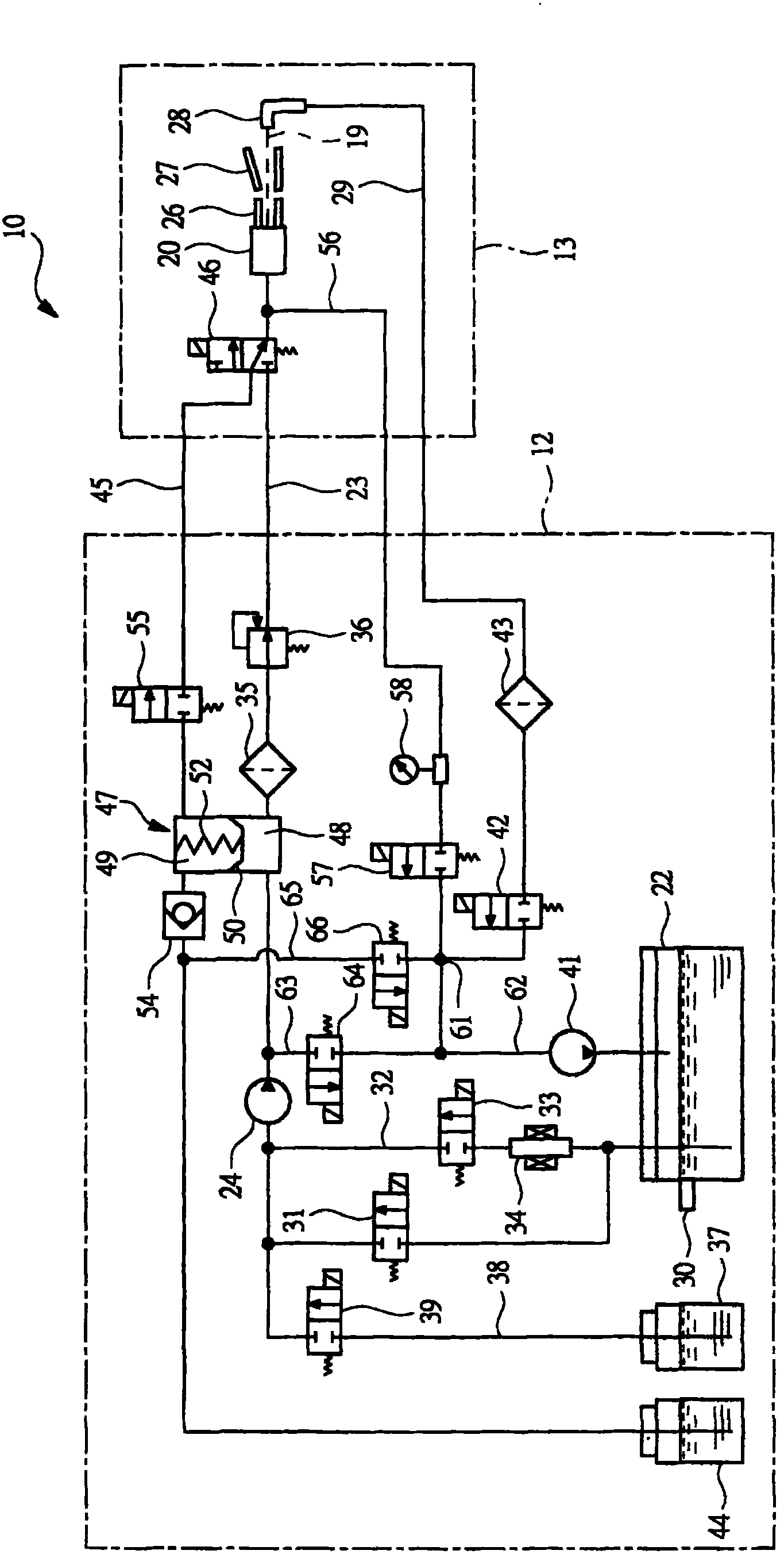

[0043] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. Such as figure 1 As shown, the inkjet recording device 10 has a device main body 12 provided with an operation display portion 11 on the front, and a printing head 13 is connected to the device main body 12 through a conduit 14 . The inkjet recording apparatus 10, for example, as figure 1 As shown, it is installed on the production line of a factory that produces food or beverages, and the packaging of food or the like is used as the object to be printed, that is, the object to be printed W, and is used to print marks on it. The device main body 12 is disposed on the upper surface of a support table not shown so as to be operable by a user. The printing head 13 is placed close to the object W conveyed by the conveyor belt 15, and the inkjet recording device 10 performs printing on the object W on the conveyor belt 15 moving in the direction indicated by the ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com