Method and device for purifying graphene oxide/graphite solution

A technology of graphene solution and purification method, which is applied in pharmaceutical formulations, cosmetic preparations, electrodialysis, etc., and can solve problems such as time-consuming, low filtration efficiency, and complicated processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

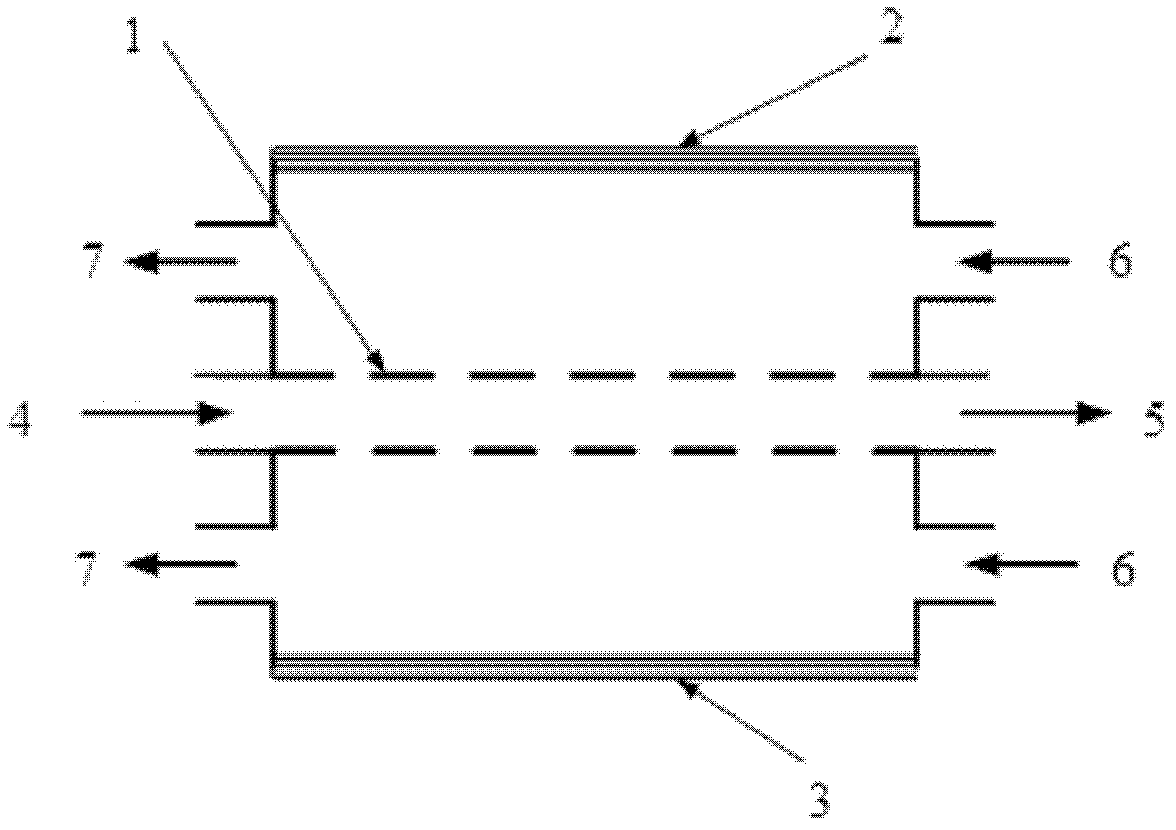

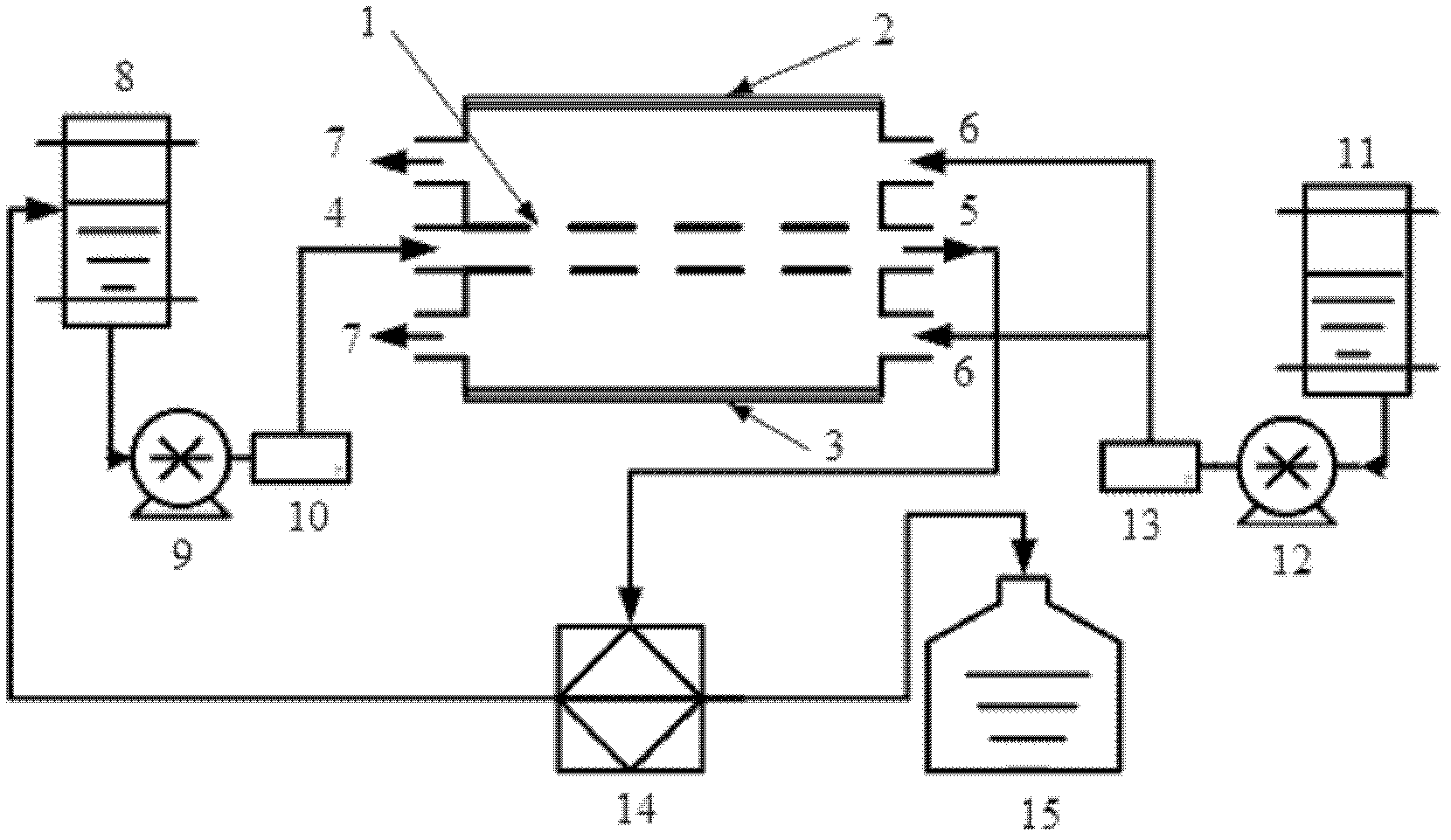

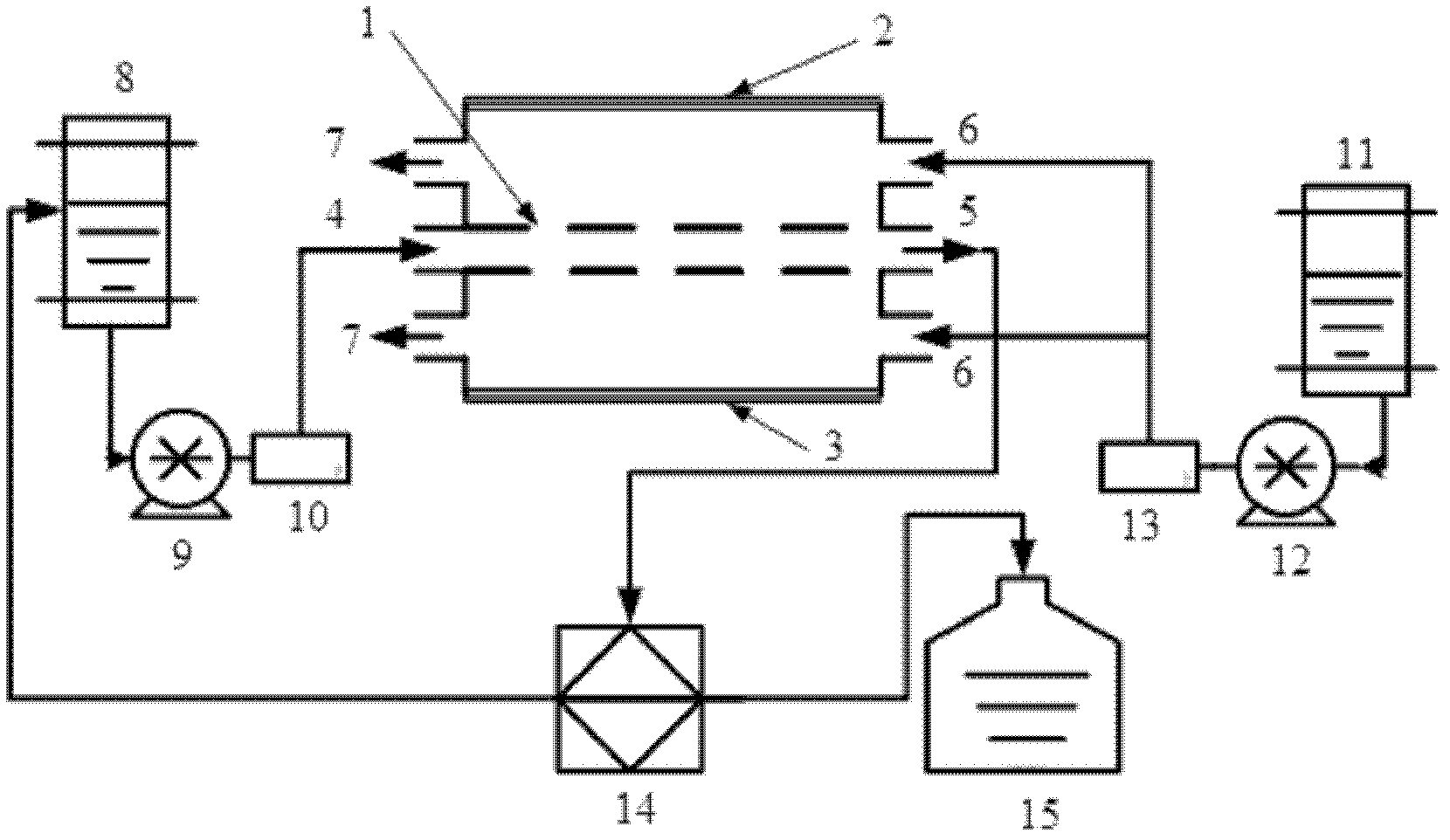

[0020] Such as Figure 1-2 Shown, a kind of device of the purifying method of graphene oxide / graphene solution, this device comprises dialysis cavity (dialysis bag) 1 and negative and positive electrode (cathode 2 and anode 3), and described negative and positive electrode is respectively arranged on dialysis cavity 1 On both sides, a graphene oxide / graphene solution channel is provided in the middle of the dialysis chamber 1, and a solvent flow channel is provided between the dialysis chamber and the cathode and anode electrodes;

[0021] The dialysis bag 1 is placed in the channel of the cathode 2 and the anode 3 made of stainless steel wire mesh, the dialysis bag 1 has a molecular weight cut-off of 5000, and the 1 mg / mL graphite oxide to be purified in the graphene oxide / graphene solution storage tank 8 The graphene oxide aqueous solution 4 enters from one end of the dialysis bag 1 through the pump 9 and the flow meter 10, and is subjected to the electric field between the ...

Embodiment 2

[0023] Place the dialysis bag in the channel of the cathode and anode electrodes composed of stainless steel wire mesh. The molecular weight cut-off of the dialysis bag is 5000. The 1 mg / mL graphene oxide aqueous solution enters from one end of the dialysis chamber and finally flows out from the other end. The voltage between the cathode and anode electrodes is 1.5V. The water flow and the graphene oxide aqueous solution pass through the channel between the cathode and anode electrodes in countercurrent. The flow rate of the graphene oxide aqueous solution is 1 mL / min, and the water flow rate is 100 mL / min. The obtained final product graphene oxide aqueous solution is filtered, and the conductivity of the filtrate is measured to be 85sm -1 .

Embodiment 3

[0025] The dialysis chamber is a chamber composed of a diaphragm; the molecular weight cutoff of the dialysis chamber is 3000. The ethanol flow is cross-flow with the graphene oxide ethanol solution. The ratio of the flow rate of graphene oxide ethanol solution to the flow rate of ethanol flow is 1:100. The concentration of the graphene oxide ethanol solution is 0.1mg / mL, and the voltage between the cathode and anode electrodes is 0.1V, and the anode and cathode electrodes are composed of a conductive coating coated on a metal film. All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com