Particle formation

a particle and particle technology, applied in the field of particle formation, can solve the problem that authors have not appeared to have achieved such high velocities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples a

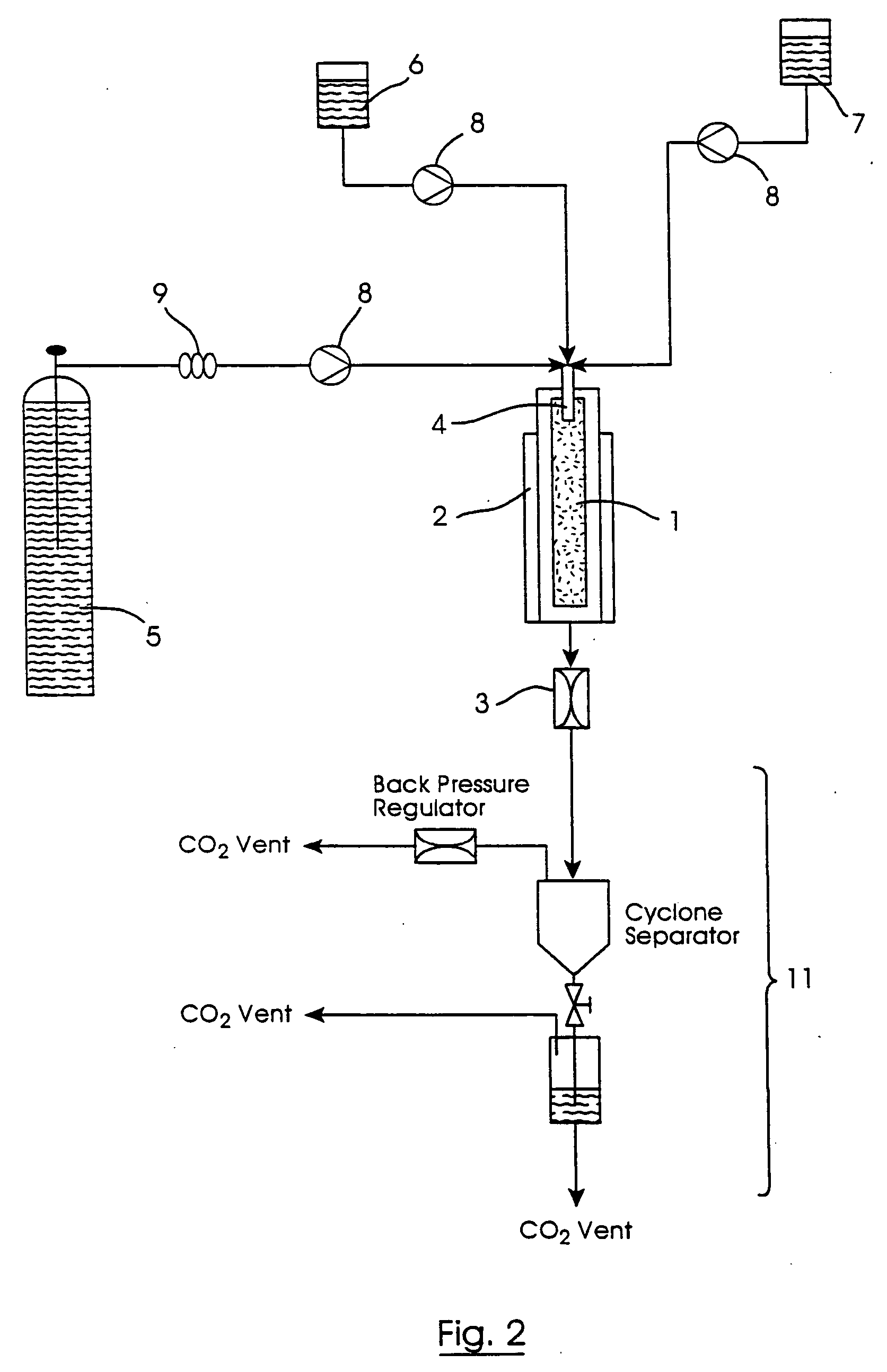

[0115] Apparatus as shown in FIG. 2, incorporating a fluid inlet assembly as shown in FIGS. 3 to 5, was used to carry out particle formation methods in accordance with the invention.

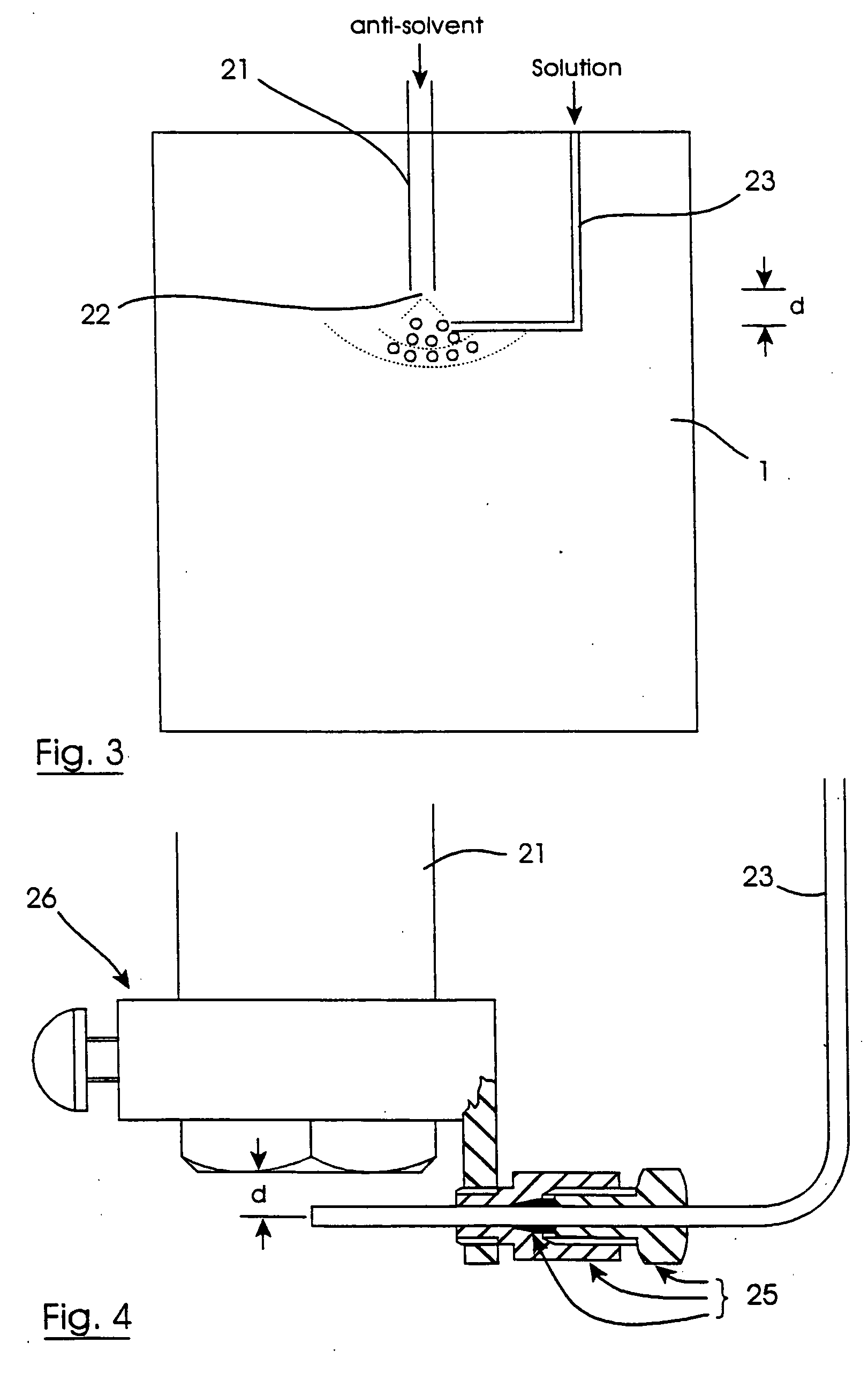

[0116] The nozzle 21 comprised a fluid inlet tube of internal diameter 0.75 mm, a convergent tip with a 60° half angle taper (with respect to the central longitudinal nozzle axis) and an outlet of diameter 0.2 mm. According to theory, this generates a fluid jet with a cone angle of approximately 20°.

[0117] The internal bore at the end of the inlet tube 23 was 0.125 mm.

[0118] The experiments investigated the effect of varying both (a) the horizontal distance x between the solution line outlet and the central axis of anti-solvent flow, and (b) the vertical distance y between the nozzle outlet 22 and the solution line outlet (y being measured, for convenience, from the top external wall of the solution inlet tube 23).

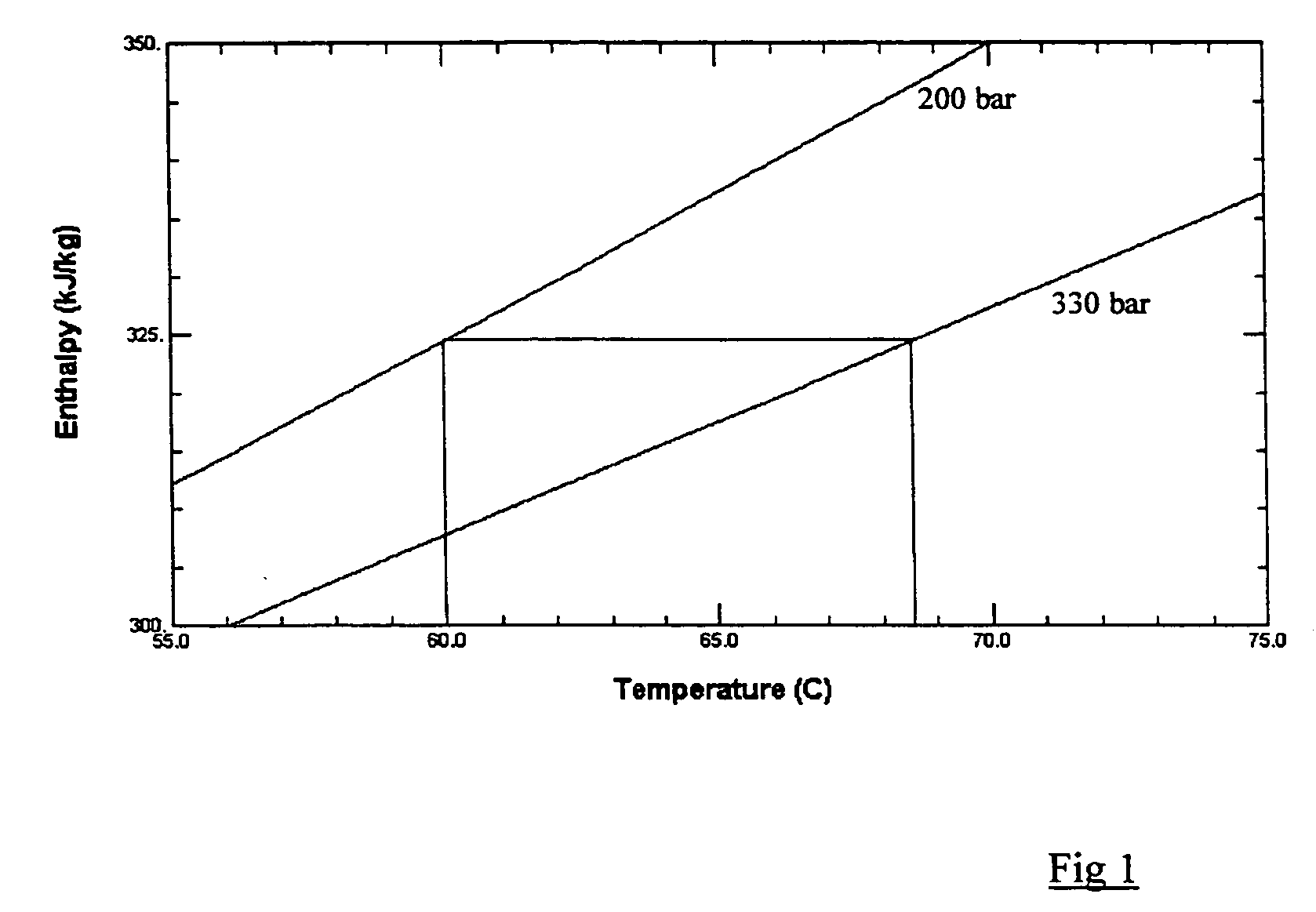

[0119] Supercritical carbon dioxide, pre-heated to 70° C., was used as the anti-solvent...

examples b

[0127] Apparatus as shown in FIG. 2, incorporating a fluid inlet assembly as shown in FIGS. 6 and 7, was used to carry out a further particle formation method in accordance with the invention. The nozzle 21 was the same as used in Examples A.

[0128] The target solution inlet comprised a fused silica capillary of length 20 mm and internal diameter 50 μm, glued into a standard 1.59 mm ({fraction (1 / 16)}″) internal diameter stainless steel tube. Its outlet, into the particle formation vessel 1, was therefore 50 μm in diameter, and its cross sectional area only 6% of that of the outlet of nozzle 21. A two-component epoxy resin was used to secure the capillary in place, under elevated temperatures (180° C.) to enhance the mechanical strength of the bond. Due to the viscous flow of the uncured resin, it was not possible to centre the capillary within the stainless steel tube.

[0129] The vertical separation “y” was ˜0.5-1 mm.

[0130] Again supercritical carbon dioxide was used as the anti-s...

examples d

[0140] Examples A were repeated, using the same nozzle 21 but with a 0.4 mm diameter outlet.

[0141] The vertical distance y between the nozzle outlet 22 and the solution tube outlet was varied between 4 and 8 mm. The solution tube outlet was positioned in line with the nozzle outlet (ie, x=0 mm).

[0142] The supercritical carbon dioxide anti-solvent was pumped at a flow rate of 200 ml / min. The salmeterol solution flow rate was 4 ml / min. The vessel temperature and pressure were as in Examples A, and the CO2 velocity at the nozzle outlet 22 was sub-sonic throughout the experiments. The run time for each experiment was approximately one hour.

[0143] Product particle sizes were measured using a Sympatec™ apparatus at 2 bar shear pressure.

[0144] The results are shown in Table 4.

TABLE 4YieldParticleParticleExpt.(%sizesizeno.y (mm)w / w)(μm)*spread**D144911.75 ± 0.05 2.25D2649 8.6 ± 0.032D38498.65 ± 0.012.04

*Volume mean diameter, representing the average of two analyses.

**Particle size sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com