Preparation method of polyphenylene terephthalamide copolymer adopting dimethylacetamide direct spinning

A manufacturing method and copolymer technology, applied in the direction of single-component copolyamide artificial filament, etc., can solve the problems of high price, insoluble, low solubility, etc., and achieve the effect of simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

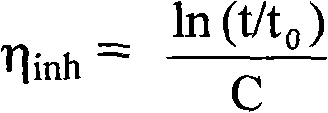

Embodiment 1

[0023] Into a 250 mL four-necked reaction flask equipped with a stirrer, dry nitrogen was passed through, and 50 mL of N,N-dimethylacetamide solution containing 2% by mass fraction of anhydrous lithium chloride was added. Add 1.50g of 4,4'-diaminodiphenyl ether and 1.42g of isophthaloyl chloride while stirring, keep the reaction system at -10-15°C, and generate inherent logarithmic viscosity after 5-15 minutes of reaction It is 0.7dL / g prepolymer. Add 0.81 g of p-phenylenediamine powder, and after it is completely dissolved, add 1.69 g of terephthaloyl chloride, and continue the reaction for 30 to 120 minutes. At this time, 0.84g CaO was added, and the reaction was continued for 2 hours in a water bath at 20-80°C to obtain a transparent, uniform and thick polymer slurry. After adjusting the polymer concentration, the stock solution could be spun in DMAC, and the PPTA copolymer was measured. The inherent viscosity is 3.6dL / g.

Embodiment 2

[0025] Into a 250 mL four-necked reaction flask equipped with a stirrer, dry nitrogen was passed through, and 50 mL of N,N-dimethylacetamide solution containing 2% by mass fraction of anhydrous lithium chloride was added. Add 1.20g of 4,4'-diaminodiphenyl ether and 1.01g of isophthaloyl chloride while stirring, keep the reaction system at -10-15°C, and generate inherent logarithmic viscosity after 5-15 minutes of reaction It is 0.6dL / g prepolymer. Add 0.97 g of p-phenylenediamine powder, and after it is completely dissolved, add 2.03 g of terephthaloyl chloride, and continue the reaction for 30 to 120 minutes. At this point add 1.09g Ca(OH) 2 , and use a water bath at 20-80°C to continue the reaction for 2 hours to obtain a transparent, uniform and thick polymerization slurry. Adjust the polymer concentration to carry out stock solution spinning in DMAC. The logarithmic viscosity of the PPTA copolymer is measured as 3.8dL / g.

Embodiment 3

[0027]In a 2L four-port reaction kettle equipped with a stirrer, dry nitrogen gas was blown in, and 400 mL of N,N-dimethylacetamide solution containing 2% by mass fraction of anhydrous lithium chloride was added. While stirring, 12.0 g of 4,4'-diaminodiphenyl ether and 11.16 g of isophthaloyl chloride were introduced, and the reaction system was kept at -10 to 15°C. After 5 to 15 minutes of reaction, an inherent logarithmic viscosity was formed. It is 0.5dL / g prepolymer. Add 6.48g of p-phenylenediamine powder, and after it is completely dissolved, add 13.72g of terephthaloyl chloride, and continue the reaction for 30-120 minutes. At this point, 6.72g of CaO was added, and the reaction was continued for 2 hours in a water bath at 20-80°C to obtain a transparent, uniform and thick polymerization slurry. After adjusting the polymer concentration, the stock solution could be spun in DMAC, and the ratio of PPTA copolymer was measured. Concentrated logarithmic viscosity is 3.5dL / g....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com