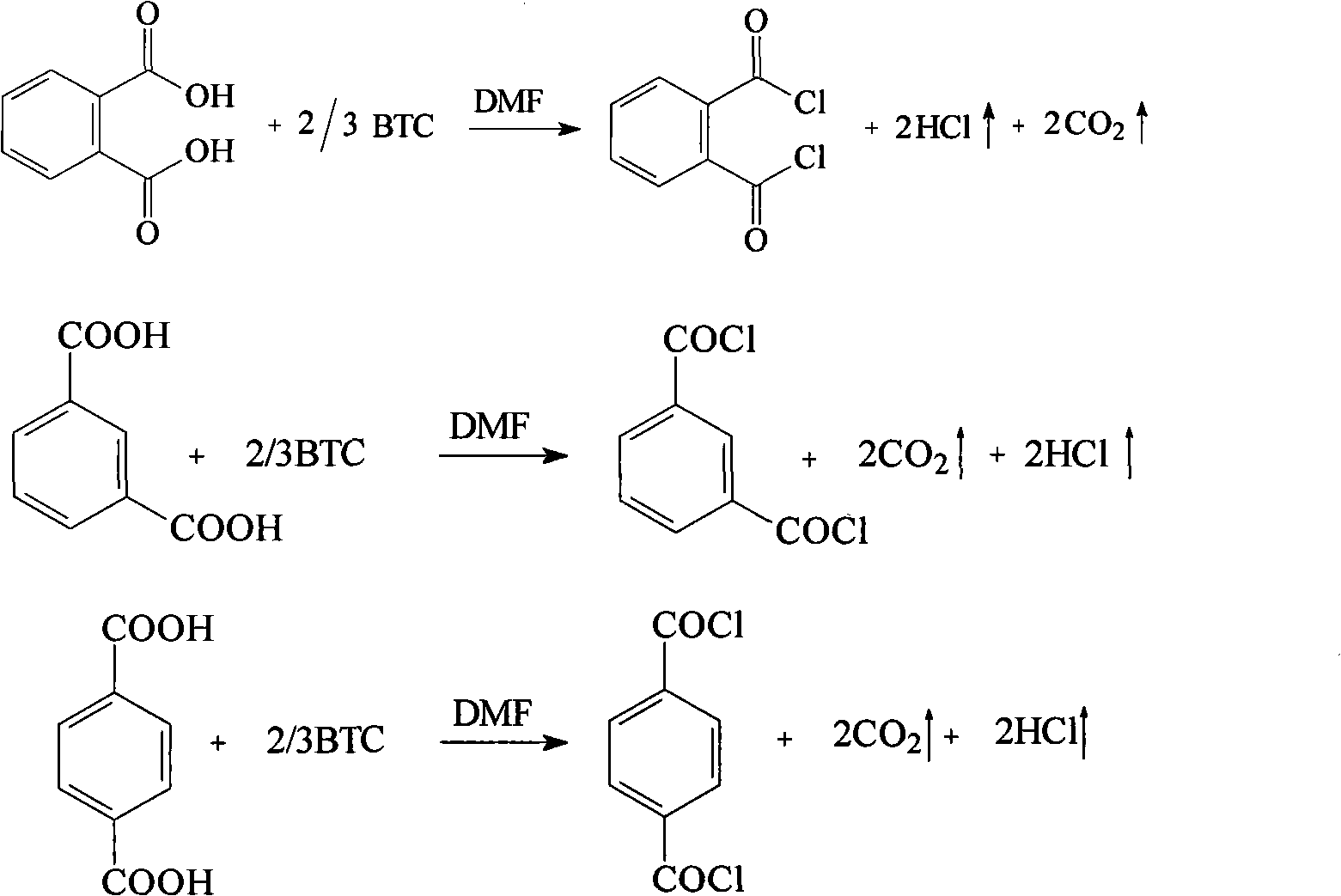

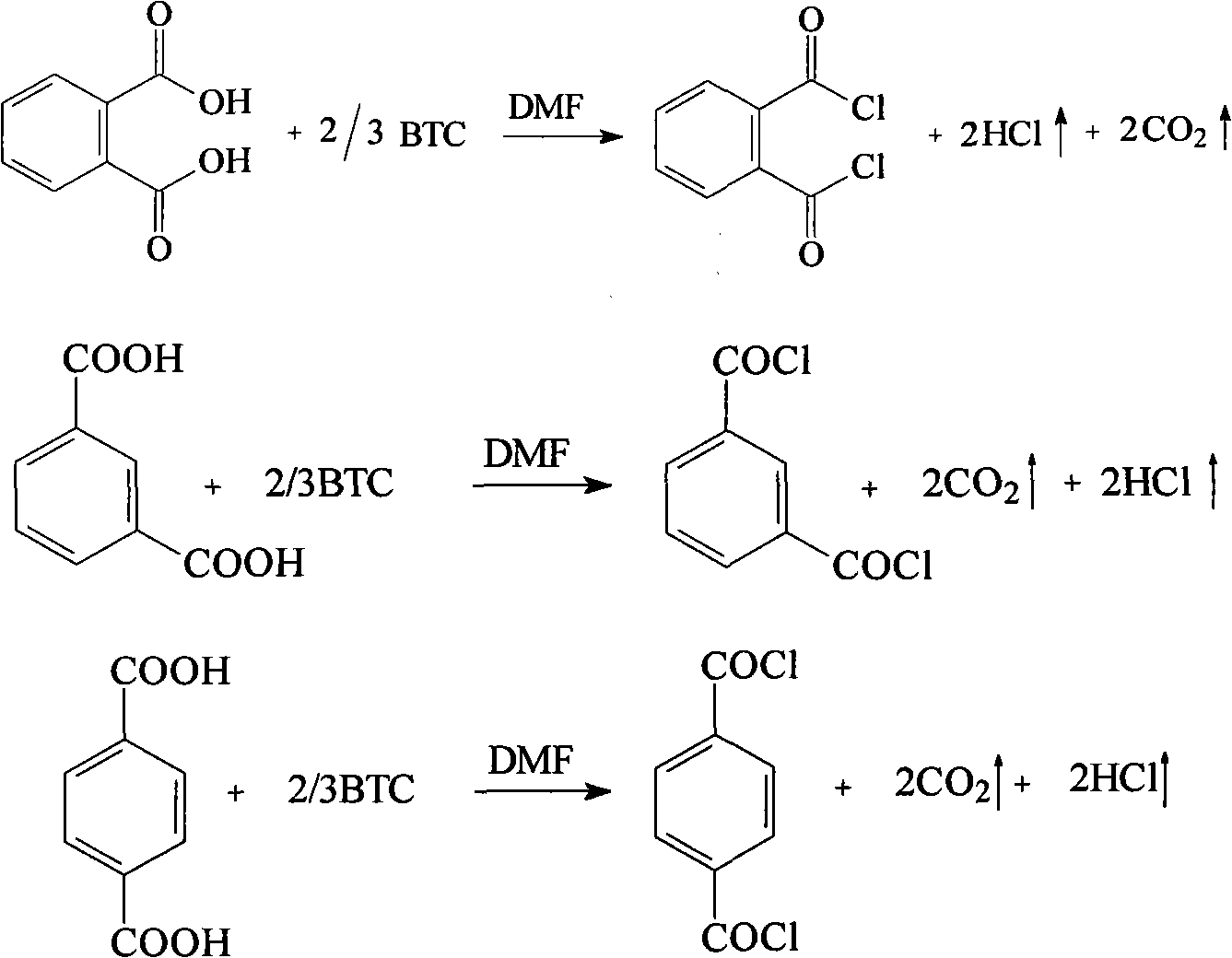

Preparation method for phthalyl chloride, m-phthaloyl chloride and paraphthaloyl chloride

A technology of terephthaloyl chloride and phthalic acid, applied in the preparation of organic compounds, preparation of carboxylate, chemical instruments and methods, etc., can solve the problems of complex post-processing, complex process operation, high temperature time, etc., and achieve Easy industrial production, reasonable process conditions, simple and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Next, solid phosgene is used as chlorinating agent, and the method for preparing o-, m-, and terephthaloyl dichlorides by reacting solid phosgene with o-, m-, and terephthalic acid is further described in detail through specific examples.

[0012] 1. The synthetic embodiment of phthaloyl chloride

[0013] (1) Weigh 8.3g of phthalic acid and put it in a three-necked flask, then add 50mL of solvent 1,2-dichloroethane and 2mL of DMF catalyst, add the solution dissolved in 150mL of 1,2 - 29.7g solid phosgene solution of dichloroethane, after adding, reflux reaction under stirring for 3 hours, filter the reaction solution and collect the 180~195°C / 0.09Mpa fraction by vacuum distillation, which is the product phthaloyl chloride, Yield 70.3%.

[0014] (2) Weigh 8.3g of phthalic acid and place it in a three-necked flask, then add 50mL of solvent 1,2-dichloroethane and 3mL of DMF catalyst, and add 130mL of phthalic acid dissolved in 130mL of 1,2-dichloro 24.7g solid phosgene s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com