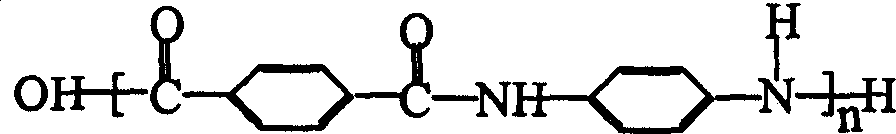

Semi-continuous preparation method of poly p-phenylene terephthalamide resin

The technology of poly-p-phenylene terephthalamide and terephthaloyl chloride is applied in the field of semi-continuous preparation of poly-p-phenylene terephthalamide resin, and can solve the problem of high requirements on metering accuracy and feeding equipment. Expensive, difficult to dissipate heat, etc., to achieve the effects of stable performance, good spinnability and good solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] In 4 500ml of anhydrous N-methylpyrrolidone (NMP) solution, add 0.30kg of anhydrous calcium chloride to prepare NMP-CaCl 2 Solution, add 0.216kg of p-phenylenediamine (PPDA) at about 15°C, let it fully dissolve, cool to 5°C, add 0.100kg of terephthaloyl chloride (TPC) for pre-condensation, and the pre-condensation polymer produced by the reaction, in Store at a constant temperature below 5°C for later use. Add the precondensed polymer and the remaining 0.306kg of terephthaloyl chloride (TPC) powder into a twin-screw reaction extruder with a diameter of Φ25, an aspect ratio of 40, and a rotational speed of 200rpm, and feed dry liquid ammonia . Control the temperature of the twin-screw reactor at 70°C for about 15 minutes to extrude the polycondensation product in the form of light yellow corn flour, let it stand for 2 hours, remove the solvent, grind it, wash it with water, and dry it to obtain a light yellow polyterephthalmic P-phenylenediamide resin powder, its intri...

Embodiment 2

[0034] In 4500ml of N-methylpyrrolidone (NMP) solution, add 0.30kg of anhydrous calcium chloride to prepare NMP-CaCl2 solution, add 0.203kg of p-phenylenediamine (PPDA) at about 20°C, let it fully dissolve, and cool To 5°C, add 0.22kg of terephthaloyl chloride (TPC) for pre-condensation, and the pre-condensation polymer produced by the reaction is kept at a constant temperature below 5°C for later use. Add the precondensed polymer and the remaining 0.203kg terephthaloyl chloride (TPC) powder into a twin-screw reaction extruder with a diameter of Φ25, an aspect ratio of 40, and a rotational speed of 200rpm to control the temperature of the twin-screw reactor At 50°C, add 0.27kg PVP K30 to the third section of the twin-screw for about 15 minutes to extrude a light yellow corn flour-like polycondensation product, let it stand for 2 hours, remove the solvent, pulverize, wash with water, and dry to obtain light yellow corn flour polycondensation product. Yellow poly-p-phenylene ter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com