Technique method for preparing mother liquor of fullbodied aramid fiber III resin and preparation equipment

A preparation process and high viscosity technology, applied in the field of preparing aramid III resin mother liquor, can solve the problems of few gel particles, high viscosity, poor heat transfer and mass transfer effect of polymerization equipment, etc., and achieve the effect of less gel particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

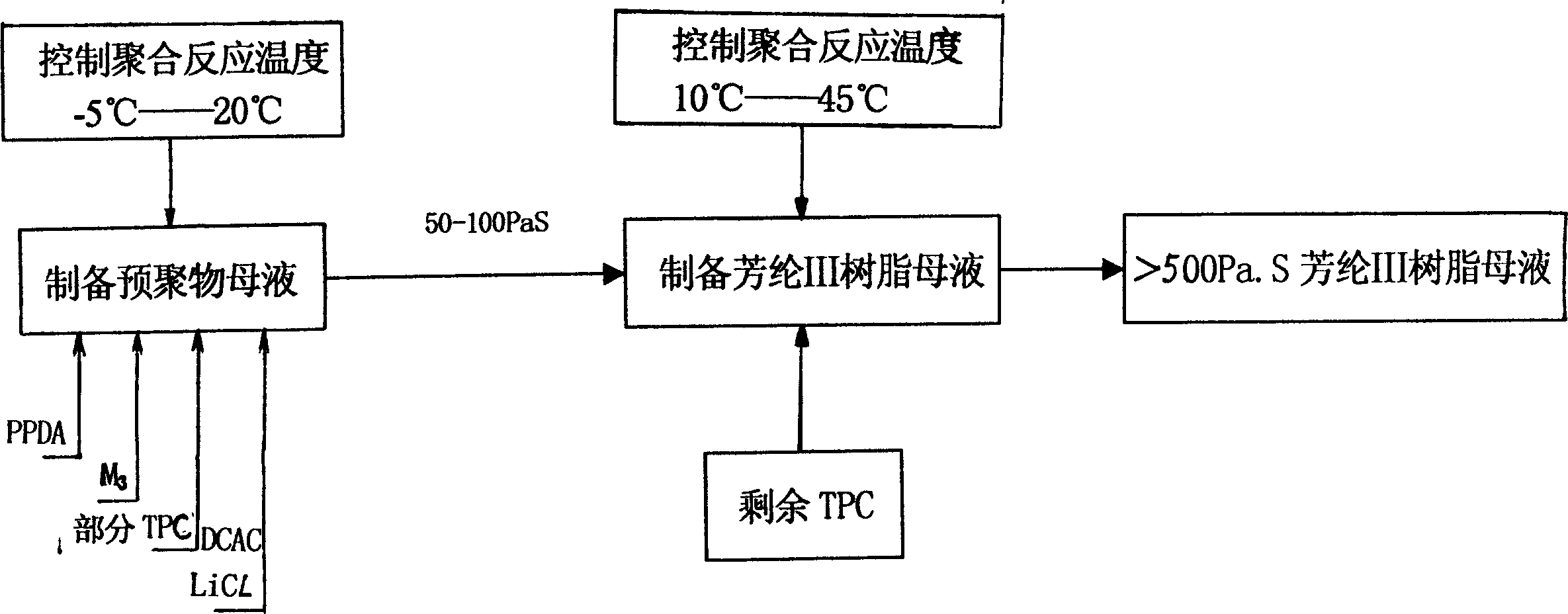

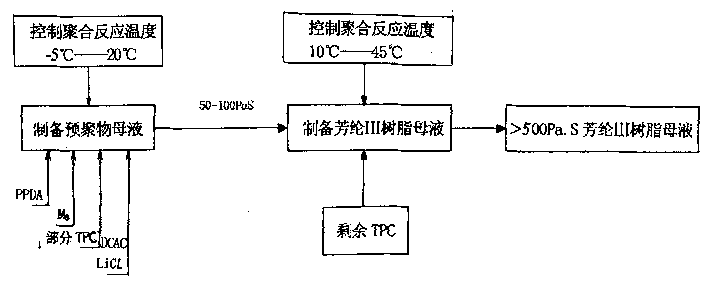

Method used

Image

Examples

Embodiment 1

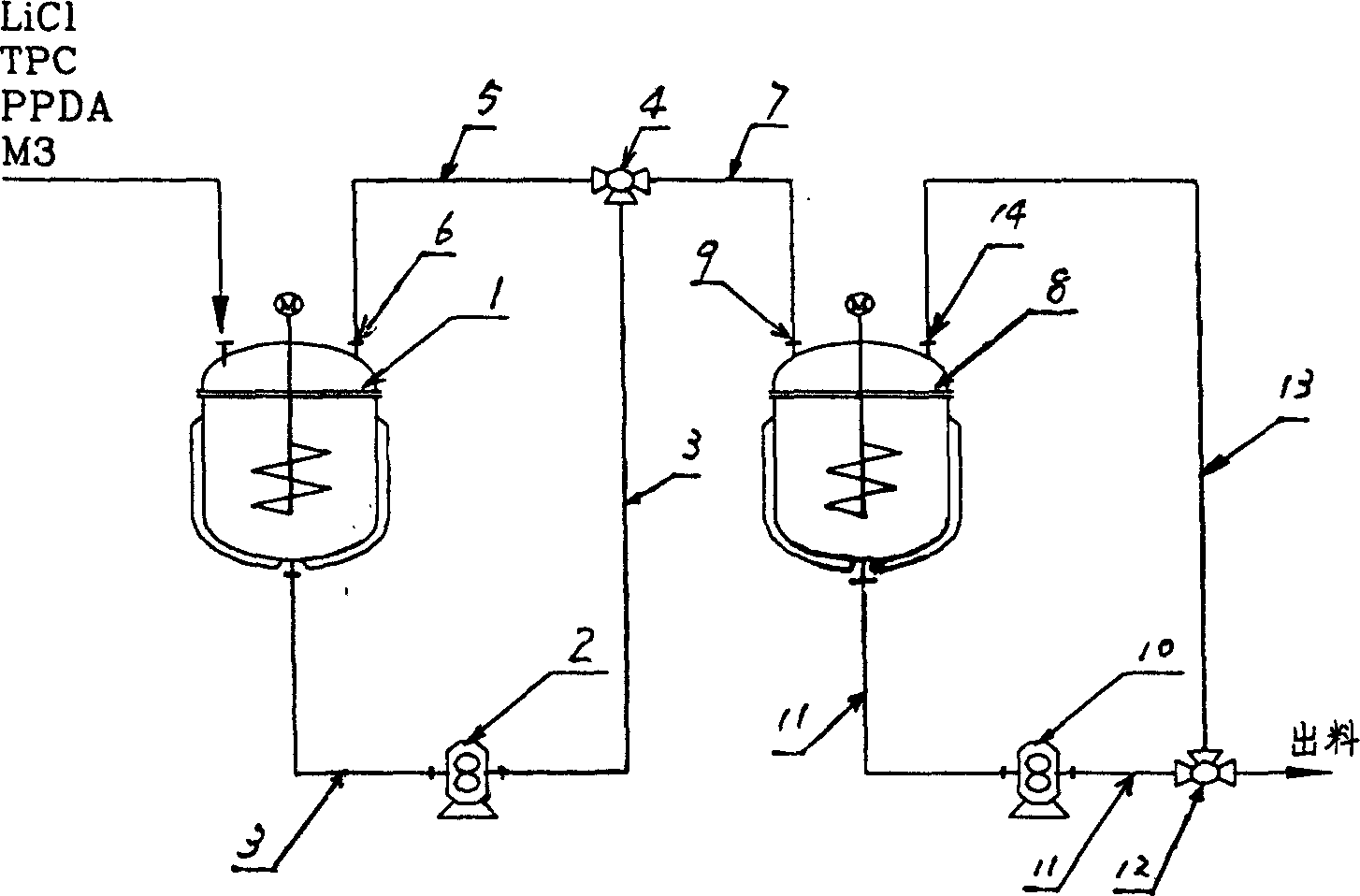

[0014] Embodiment 1: M 3 Dissolve the monomer and p-phenylenediamine (PPDA) in N,N-dimethylacetamide (DMAC) solvent containing LiCl, lower the solution temperature to -5°C to 5°C, add part of terephthaloyl chloride, After the dynamic viscosity of the solution reaches 50-100Pa.S, it is transported to the polymerization reactor, and the remaining amount of terephthaloyl chloride is added, and the solution can be discharged after the dynamic viscosity of the solution reaches 500Pa.S. The raw material formula is as follows: DMAC 1410g PPDA 11.25gLiCI 51g TPC 42.2gM 3 23.3g adopted figure 2 The device shown is the synthetic resin mother liquor. When the pre-polymerization reactor adopts an ordinary polymerization reactor without an external forced circulation system, and the polymerization reactor adopts an external forced circulation system, the properties of the prepared aramid III resin mother liquor and its fibers are shown in Table 1.

[0015] Table ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com