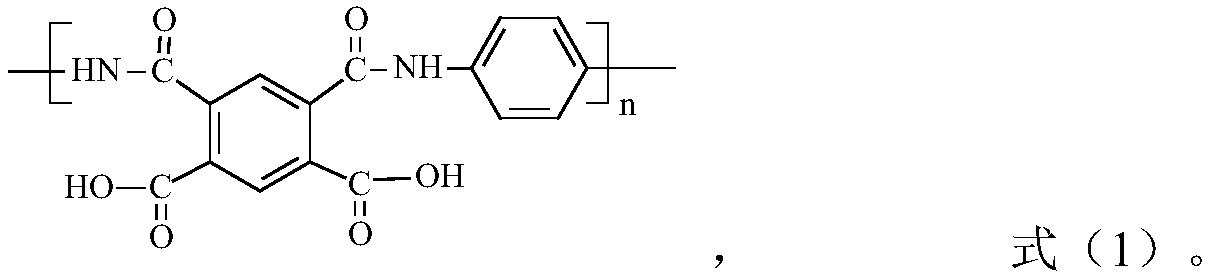

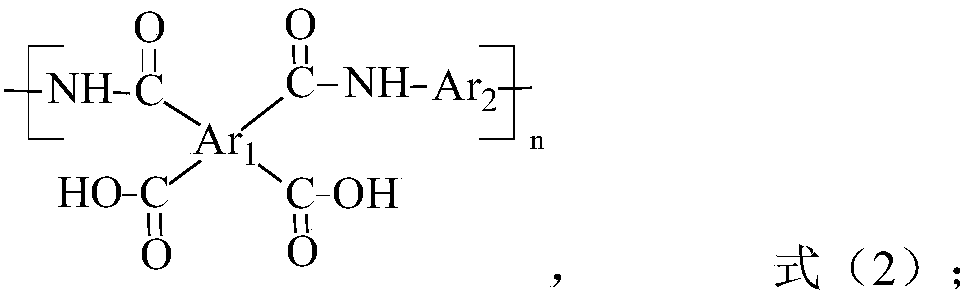

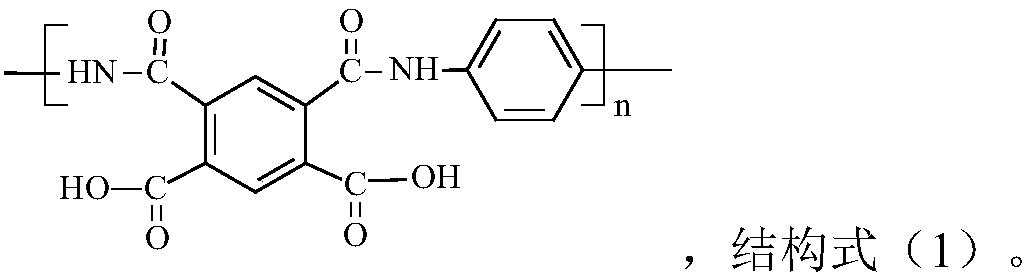

Polyimide film with stable size and preparation method thereof

A technology for polyimide film and polyamic acid film, which is applied in the field of polyimide film and its preparation, can solve the problems of high thermal expansion coefficient of polyimide film, difficult process control, product quality decline, etc. Improve regularity and bulk density, achieve dimensional stability and overall performance, and reduce CTE

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] 1. Stock solution preparation

[0060] (1) Dissolve p-phenylenediamine in N,N-dimethylacetamide, 2 Stir under protection, after completely dissolving, continuously and uniformly add pyromellitic dianhydride (dianhydride, diamine molar ratio 0.98, solid content 15%), feed time is 3 hours, after pyromellitic dianhydride is added After fully reacting for 3 hours, add 4-phenylethynylphthalic anhydride capping agent to the above system, and continue stirring for 2 hours to obtain a polyamic acid A solution.

[0061] (2) Dissolve 4,4'-diaminodiphenyl ether in N,N-dimethylacetamide, 2 Stir under protection, after complete dissolution, continuously and uniformly add 3,3',4,4'-biphenyltetracarboxylic dianhydride (the molar ratio of dianhydride and diamine is 0.98, the solid content is 15%), and the feeding time is 3 hours After the dianhydride was added, the polyamic acid B solution was obtained after fully reacting for 3 hours.

[0062] (3) Mix the polyamic acid A solution a...

Embodiment 2

[0069] 1. Stock solution preparation

[0070] (1) Dissolve p-phenylenediamine in N,N-dimethylacetamide, 2 Stir under protection, after completely dissolving, add pyromellitic dianhydride (dianhydride to diamine molar ratio 0.95, solid content 25%) continuously and at a uniform speed, feed time is 6 hours, after pyromellitic dianhydride is added After fully reacting for 10 hours, add a phenylethynyl trimellitic anhydride capping agent to the above system, and continue stirring for 3 hours to obtain a polyamic acid A solution.

[0071] (2) Dissolve 4,4'-diaminodiphenyl ether in N,N-dimethylacetamide, 2 Stir under protection, after completely dissolving, continuously and uniformly add 3,3',4,4'-benzophenone tetracarboxylic dianhydride (dianhydride, diamine molar ratio 1.03, solid content 25%), the feeding time is After 4 hours, the polyamic acid B solution was obtained after fully reacting for 6 hours after adding the dianhydride.

[0072] (3) Mix the polyamic acid A solution ...

Embodiment 3

[0076] 1. Stock solution preparation

[0077] (1) Dissolve p-phenylenediamine in N,N-dimethylpyrrolidone, 2 Stir under protection, after completely dissolving, continuously and uniformly add pyromellitic dianhydride (dianhydride, diamine molar ratio 0.992, solid content 12%), feed time is 4 hours, after pyromellitic dianhydride is added After fully reacting for 2 hours, add a phenylethynyl trimellitic anhydride capping agent to the above system, and continue stirring for 2 hours to obtain a polyamic acid A solution.

[0078] (2) Dissolve diaminodiphenylmethane in N,N-dimethylpyrrolidone, stir at 20°C under N2 protection, after completely dissolving, add 3,3',4,4'-biphenyl tetra Formic acid dianhydride (dianhydride, diamine molar ratio 0.996, solid content 12%), the feeding time is 2 hours, after the dianhydride is added, fully react for 10 hours to obtain the polyamic acid B solution.

[0079] (3) Mix the polyamic acid A solution and the polyamic acid B solution at a mass ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com