Membrane coating liquid and water-based nano-para-aramid coated membrane

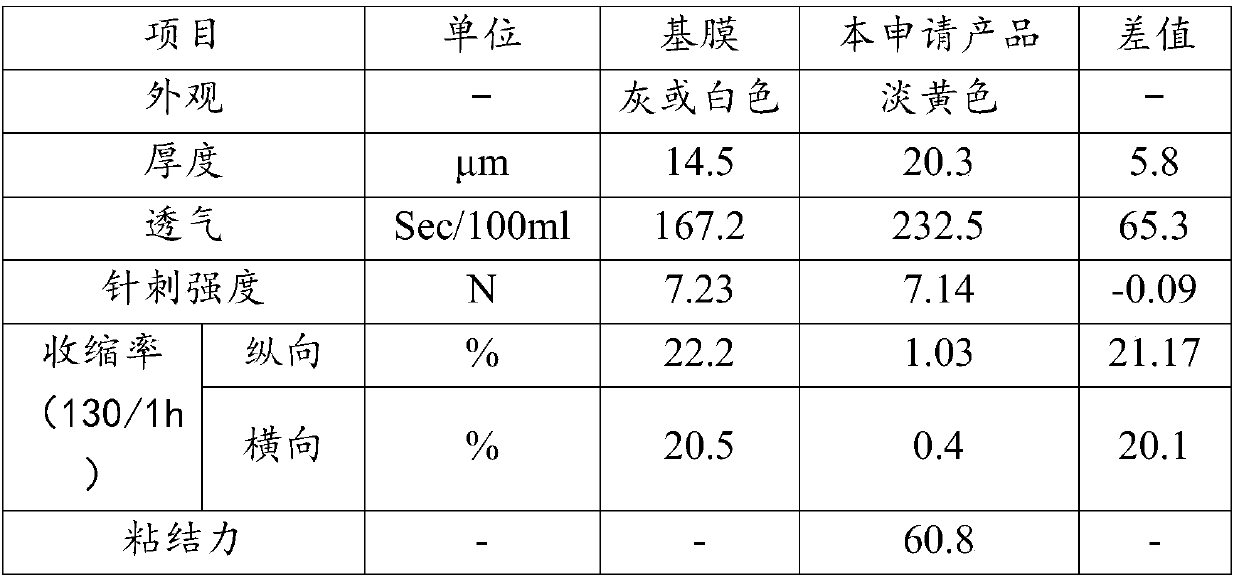

A technology of para-aramid fiber and coating liquid is applied in the field of diaphragm coating liquid and water-based nano-para-aramid fiber coating diaphragm, which can solve the problem of high product cost and achieve the effects of low cost, good reliability and good performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Under dry inert gas atmosphere and stirring conditions (stirring speed is 400 rpm), control the system temperature at 90°C, add co-solvent calcium chloride to N-methylpyrrolidone (NMP) and dissolve it, the amount of co-solvent added Be 5% of NMP quality; Then add polyethylene glycol (addition amount is 2% of the quality of N-methylpyrrolidone), stir about 1 hour, then reaction system temperature is down to normal temperature, adds p-phenylenediamine (addition amount 2% of the quality of N-methylpyrrolidone), continue to stir, after the p-phenylenediamine dissolves completely, the temperature of the reaction system drops to 3° C. ), increase the rotating speed to 800 revolutions per minute, so that terephthaloyl chloride is completely dissolved, and continue to react for 40 minutes, then the reaction system is heated to 75 ° C, and the reaction is continued to obtain the primary polymer of p-aramid fiber;

[0038] Add N-methylpyrrolidone (addition amount is 5% of the qua...

Embodiment 2

[0042]Under dry inert gas atmosphere and stirring conditions (stirring speed is 600 rpm), control the system temperature at 100°C, add co-solvent calcium chloride to N-methylpyrrolidone (NMP) and dissolve it, the amount of co-solvent added It is 9% of NMP quality; Then add polyethylene glycol (7% of the quality of N-methylpyrrolidone), stir about 1 hour, then reaction system temperature is down to normal temperature, adds p-phenylenediamine (addition amount 3% of the quality of N-methylpyrrolidone), continue to stir until the temperature of the reaction system drops to 7°C after p-phenylenediamine is completely dissolved, then add terephthaloyl dichloride (p-phenylenediamine and terephthaloyl dichloride The molar ratio is 1:1.007), increase the rotation speed to 1000 rpm, so that the terephthaloyl chloride is completely dissolved, and continue to react for 50 minutes, then the reaction system is heated to 85°C, and the reaction is continued to obtain the primary polymer of p-ar...

Embodiment 3

[0047] Under dry inert gas atmosphere and stirring conditions (stirring speed is 500 rpm), control the system temperature at 95°C, add co-solvent lithium chloride to N-methylpyrrolidone (NMP) and dissolve it, the amount of co-solvent added It is 7% of NMP quality; Then add polyethylene glycol (addition is 5% of the quality of N-methylpyrrolidone), stir about 1 hour, then reaction system temperature is down to normal temperature, adds p-phenylenediamine (addition 2.5% of the quality of N-methylpyrrolidone), continue to stir, until the temperature of the reaction system drops to 5°C after p-phenylenediamine is completely dissolved, then add terephthaloyl dichloride (p-phenylenediamine and terephthaloyl dichloride The molar ratio is 1:1.01), increase the rotation speed to 900 rpm, so that the terephthaloyl chloride is completely dissolved, and continue the reaction for 45 minutes, then the reaction system is heated to 80 ° C, and the reaction is continued to obtain the primary pol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com