Random copolymerization polysulfonamide spinning liquid and preparation method thereof

A polysulfone amide, random copolymerization technology, applied in the direction of spinning solution preparation, single-component copolymerized polyamide artificial filament, filament molding treatment, etc., can solve problems that have not been seen yet, and achieve convenient production and low cost , the effect of conditional optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1: Preparation of polysulfone ether aramid spinning solution

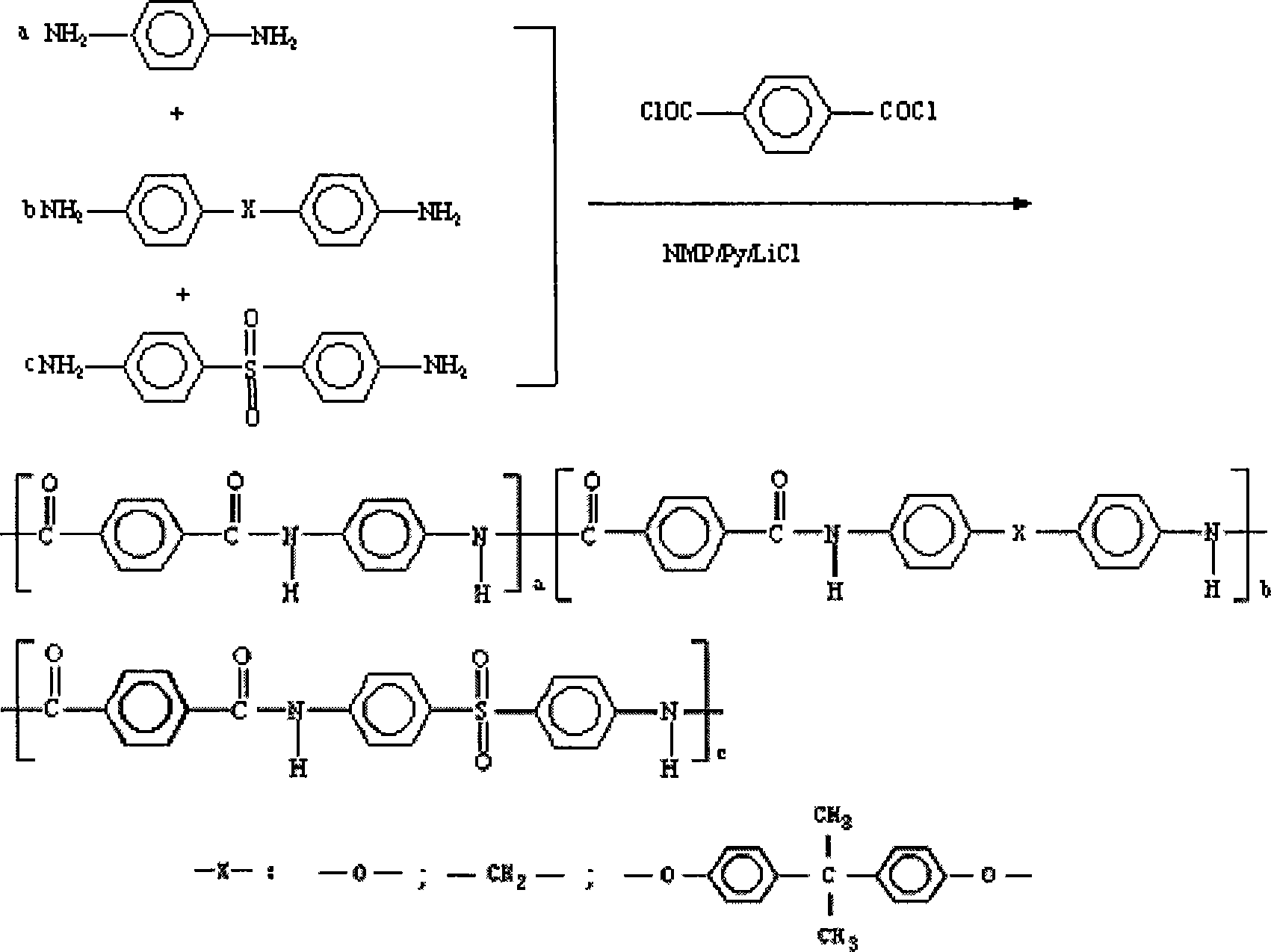

[0026] In a 500 ml four-necked bottle equipped with mechanical stirring and nitrogen inlet, add 200 ml of NMP (N-methyl-2-pyrrolidone) solvent and 1.0 g of lithium chloride, and heat in a water bath at 70°C to completely dissolve lithium chloride . Dissolve while stirring under the protection of nitrogen, followed by 2.34 mmoles of 4,4'-diaminodiphenyl ether, 2.34 mmoles of 4,4'-diaminodiphenylsulfone and 3.12 mmoles of p-phenylenediamine, 7.80 mmoles mol of terephthaloyl chloride, and then reacted at room temperature for 6 hours. The specific reaction process is shown in Figure (1).

[0027] Use CaO to neutralize the polymer reaction solution, adjust the pH value to 6-7, and then filter and defoam, then it can be directly used as spinning solution. At 35° C., the falling ball viscosity of the spinning solution was tested for 50 seconds (the falling ball is a steel ball with a diameter of 3 mm, an...

Embodiment 2

[0029] Embodiment two: the preparation of polysulfone methane aromatic amide spinning solution

[0030] In the 500 milliliter four-necked bottle that is equipped with mechanical stirring and nitrogen inlet, add the NMP (N-methyl-2-pyrrolidone) solvent of 200 milliliters and the lithium chloride of 3.0 grams, 70 ℃ of water baths make lithium chloride dissolve completely, Then dissolve while stirring under nitrogen protection, successively 6 mmoles of 4,4'-diaminodiphenylmethane, 6 mmoles of 4,4'-diaminodiphenylsulfone and 18 mmoles of p-phenylenediamine, 30 Millimoles of terephthaloyl chloride. Then react at normal temperature for 6 hours. The specific reaction process is shown in Figure (1).

[0031] Use CaO to neutralize the polymer reaction solution, adjust the pH value to 6-7, and then filter and defoam, then it can be directly used as spinning solution.

Embodiment 3

[0032] Example 3: Preparation of polysulfone bisphenol A aromatic amide spinning solution

[0033] In a 500 ml four-necked bottle equipped with mechanical stirring and nitrogen inlet, add 200 ml of NMP (N-methyl-2-pyrrolidone) solvent and 4.0 g of calcium chloride, and completely dissolve lithium chloride in a 70° C. water bath. Cool to 0°C with an ice-water bath, add 5.2 ml of pyridine, then dissolve under nitrogen protection while stirring, add 16 mmol of polysulfone bisphenol A aromatic amide, 16 mmol of 4,4'-diaminobis Phenylsulfone and 8 mmoles of p-phenylenediamine, 40 mmoles of terephthaloyl chloride. Then react at normal temperature for 6 hours. The specific reaction process is shown in Figure (1).

[0034] Use CaO to neutralize the polymer reaction solution, adjust the pH value to 6-7, and then filter and defoam, then it can be directly used as spinning solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com