Nitrogen-doped porous carbon nanotube material and its preparation method and use in super capacitor electrode

A technology of nitrogen-doped porous carbon and carbon nanotubes, applied in hybrid capacitor electrodes, nanotechnology, nanotechnology, etc., can solve problems such as hindering the contact between electrolyte and electrode active material, low specific surface area, and unsatisfactory performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

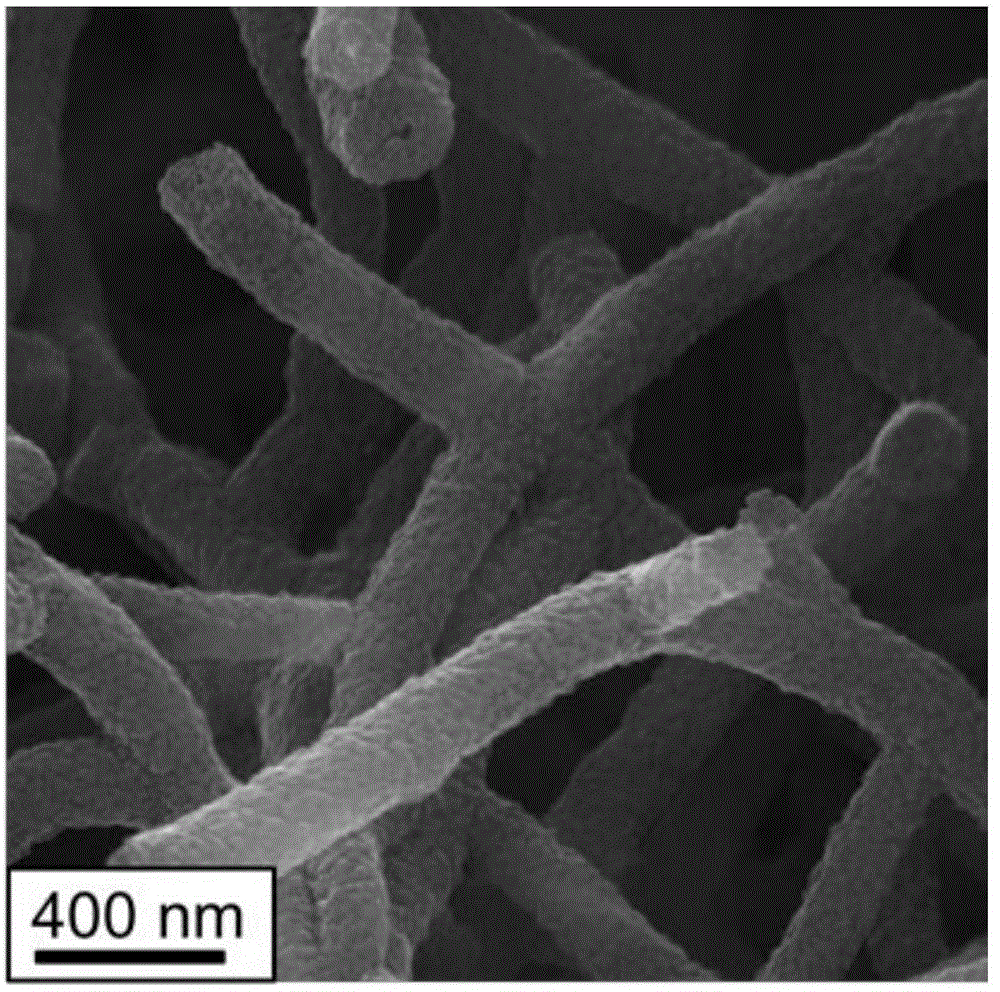

[0018] Weigh 2mL of aniline and 6.84g of ammonium persulfate and dissolve them in 100ml of deionized water respectively to prepare the aniline solution and ammonium persulfate solution. After stirring evenly, let stand at 5°C for 30 minutes, then quickly pour the ammonium persulfate solution into the aniline solution , 5°C for 24 hours. The suction-filtered products were washed with deionized water until the filtrate was colorless, and dried at 50° C. to obtain polyaniline nanotubes.

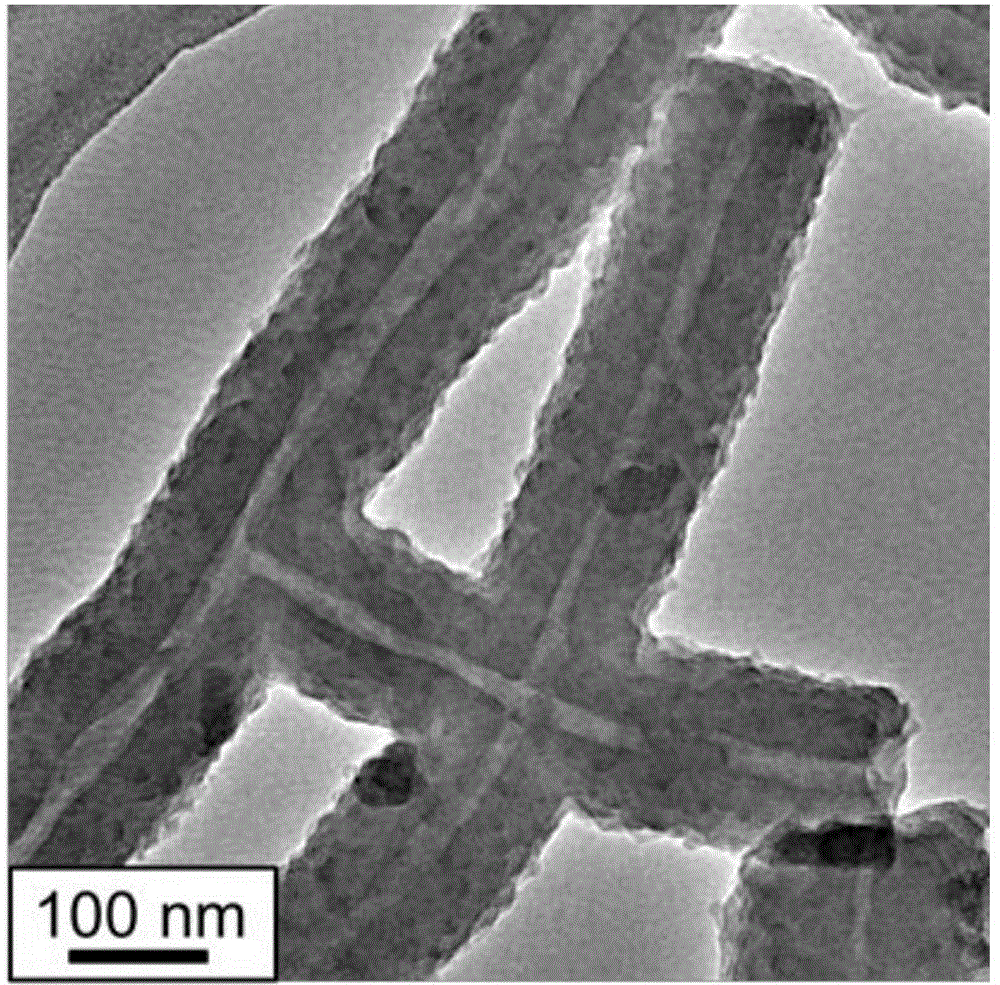

[0019] Polyaniline nanotubes were loaded into alumina crucibles as carbon precursors, pre-oxidized in air at 200 °C for 2 hours, then placed in a horizontal carbonization furnace, heated under nitrogen atmosphere, and the heating rate was 1 °C min -1 , the temperature was raised from room temperature to 700° C., and kept for 2 hours to obtain polyaniline-based carbon nanotubes.

[0020] Take the obtained carbonized product, mix it with potassium hydroxide at a ratio of 1:4 and put it into a hig...

Embodiment 2

[0023] The preparation method of polyaniline carbon nanotubes is different from that of Example 1 in that during the activation process, the activation temperature is 600° C. and the temperature is kept for 2 hours to obtain nitrogen-doped porous carbon nanotubes.

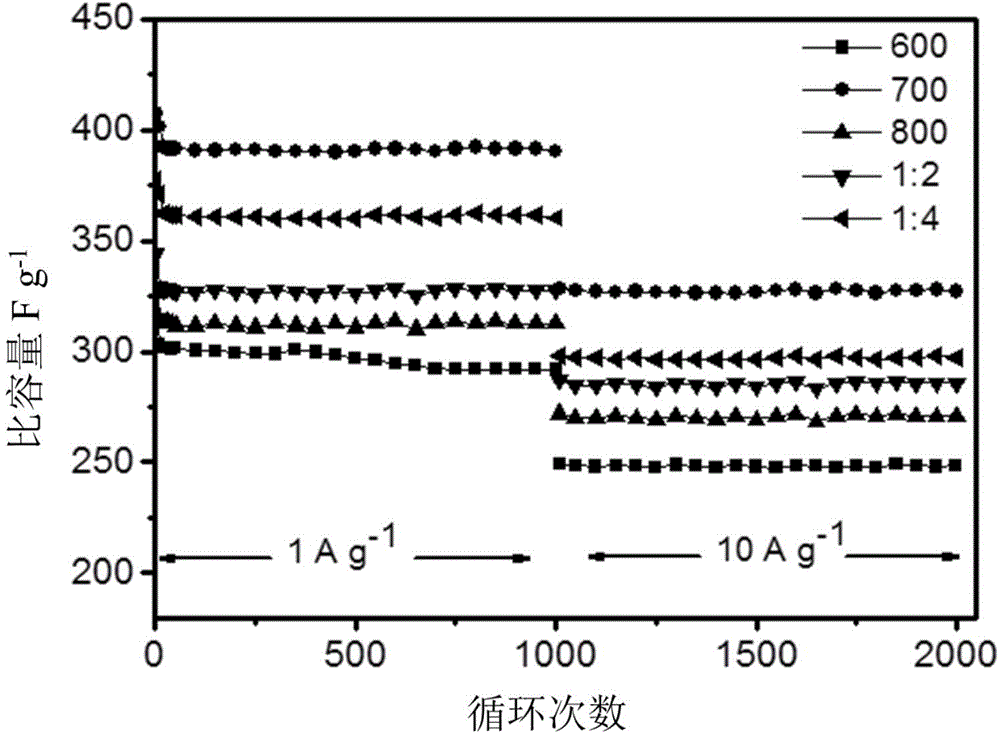

[0024] as attached image 3 The nitrogen-doped porous carbon nanotubes obtained by activation treatment at 600℃ are shown at a current density of 1Ag -1 1000 times down cycle capacity is 292Fg -1 , at a current density of 10Ag -1 1000 cycles capacity of 248Fg -1 .

Embodiment 3

[0026] The preparation method of polyaniline carbon nanotubes is the same as that in Example 1, except that the activation temperature is 800° C., and the temperature is kept for 2 hours to obtain nitrogen-doped porous carbon nanotubes.

[0027] as attached image 3 The nitrogen-doped porous carbon nanotubes obtained by carbonization treatment at 800℃ are shown at a current density of 1Ag -1 The capacity is 312Fg for 1000 times of down cycle -1 , at a current density of 10Ag -1 1000 cycles capacity of 270Fg -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com