Aliphatic-polyamide-modified copolyester, aliphatic-polyamide-modified copolyester fiber, and preparation methods thereof

A technology of aliphatic polyamide and copolyester, applied in fiber chemical characteristics, melt spinning method, stretch spinning method, etc., can solve spinning instability, affecting spinnable fabric performance, and poor heat resistance of polyester fiber and other problems, to achieve the effect of reducing the crystallization performance and glass transition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

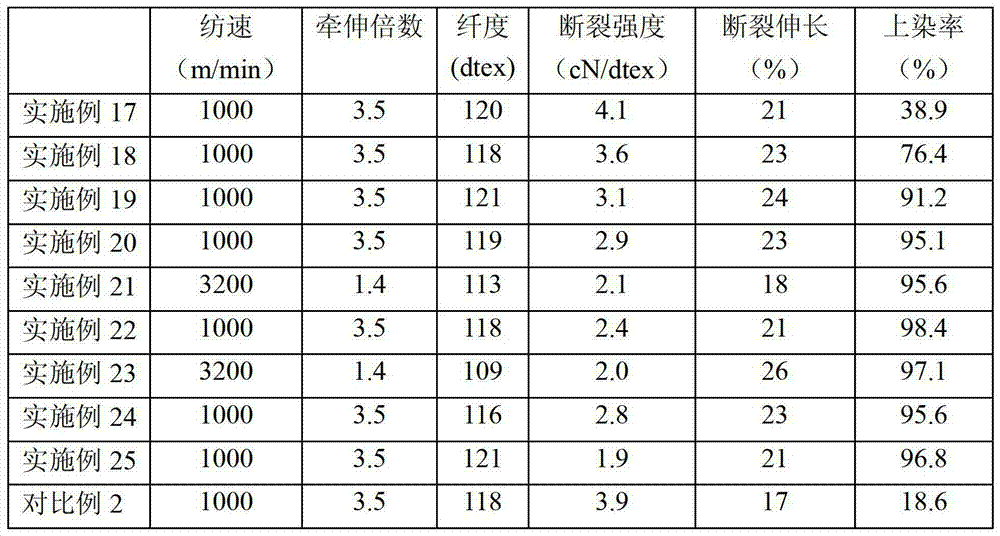

Examples

preparation example Construction

[0029] At the same time, in one embodiment of the present invention, a preparation method of aliphatic polyamide modified copolyester is provided, comprising the following steps: mixing terephthalic acid with ethylene glycol, and obtaining esterification after esterification Product; Diethylene glycol isophthalate-5-sulfonic acid alkali metal salt and aliphatic polyamide are added in the esterification product, and copolymerization reaction obtains aliphatic polyamide modified copolyester; Wherein, terephthalic acid Formic acid, ethylene glycol, alkali metal salt of diethylene glycol isophthalate-5-sulfonic acid are added according to the molar ratio of 1:1.05~2:0.01~0.1, and the amount of aliphatic polyamide added is the weight of terephthalic acid 1 ~ 40wt% of.

[0030] Preferably, in the preparation method of the above-mentioned aliphatic polyamide modified copolyester, the alkali metal salt of diethylene glycol isophthalate-5-sulfonic acid is added in an amount of 3 to 10 ...

Embodiment 1

[0042] Esterify terephthalic acid and ethylene glycol with a molar ratio of 1:1.1, the reaction temperature is 270°C, and the reaction time is 3h. Then add diethylene glycol isophthalate-5-potassium sulfonate equivalent to 1.5% molar weight of terephthalic acid and polycondensation catalyst III equivalent to 1wt% nylon 66 and 0.04wt% of terephthalic acid weight Antimony oxide is copolymerized, the reaction temperature is 290°C, and the reaction time is 2 hours. After the reaction is completed, the material is discharged and pelletized to obtain aliphatic polyamide modified copolyester chips.

Embodiment 2

[0044] Esterify terephthalic acid and ethylene glycol with a molar ratio of 1:1.05, the reaction temperature is 270°C, and the reaction time is 6h. Then add diethylene glycol isophthalate-5-sodium sulfonate corresponding to 1.5% molar weight of terephthalic acid and polycondensation catalyst three corresponding to 5wt% nylon 66 and 0.05wt% of terephthalic acid weight Antimony oxide is copolymerized, the reaction temperature is 280°C, and the reaction time is 3 hours. After the reaction is completed, the material is discharged and pelletized to obtain aliphatic polyamide modified copolyester chips.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com