High-weather-resistance ultra-transparent thermoplastic polyurethane elastomer and preparation method thereof

A thermoplastic polyurethane and ultra-transparent technology, applied in the field of polyurethane, can solve the problems of not being able to meet the requirements of high transparency and transparency, and achieve the effects of good yellowing resistance, reduced crystallinity, and good weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

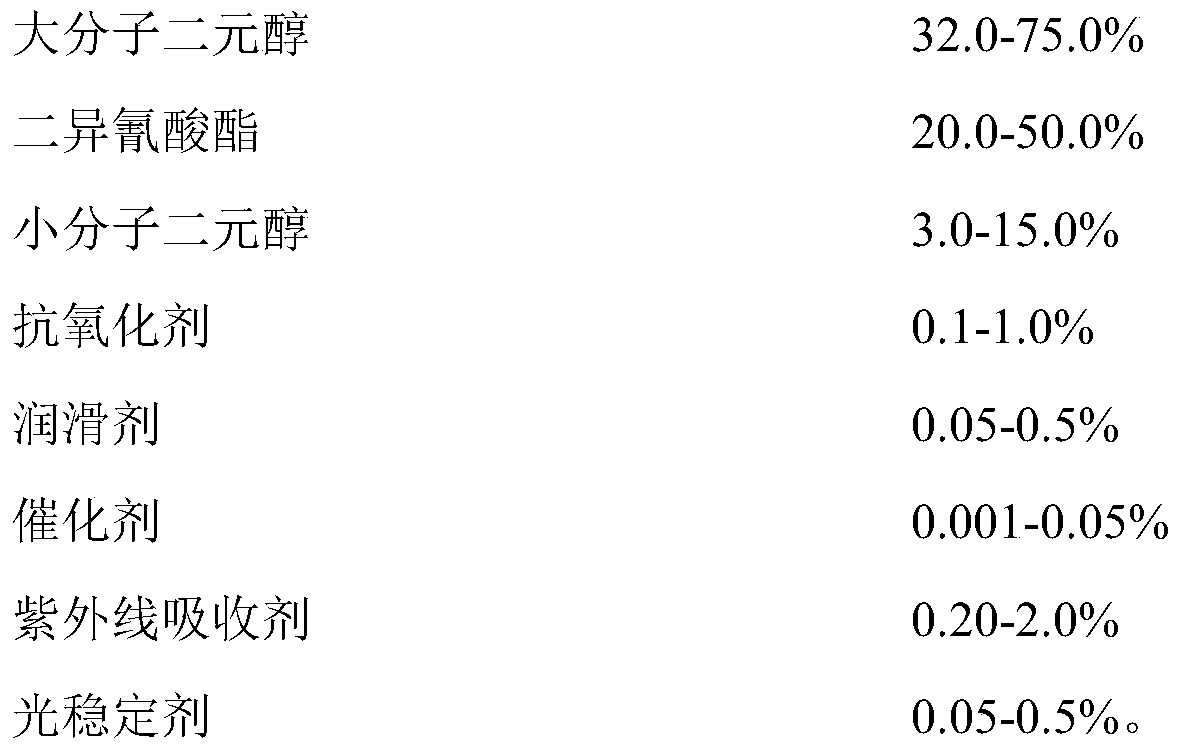

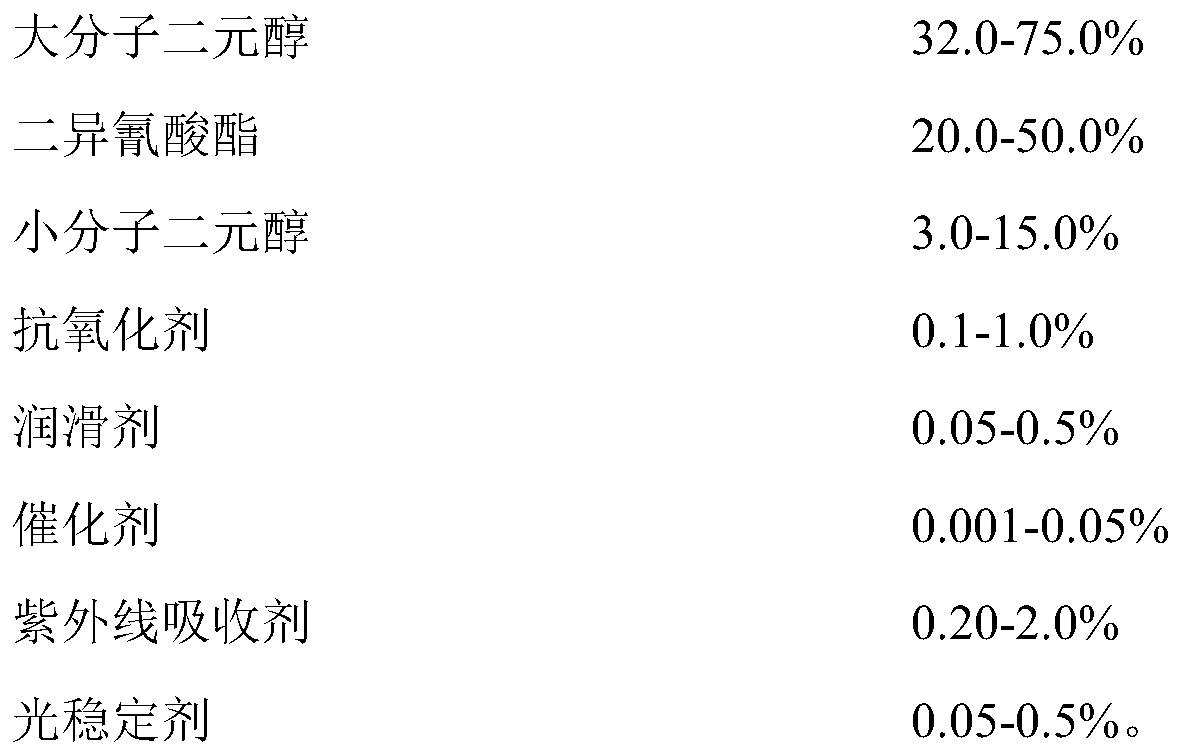

Method used

Image

Examples

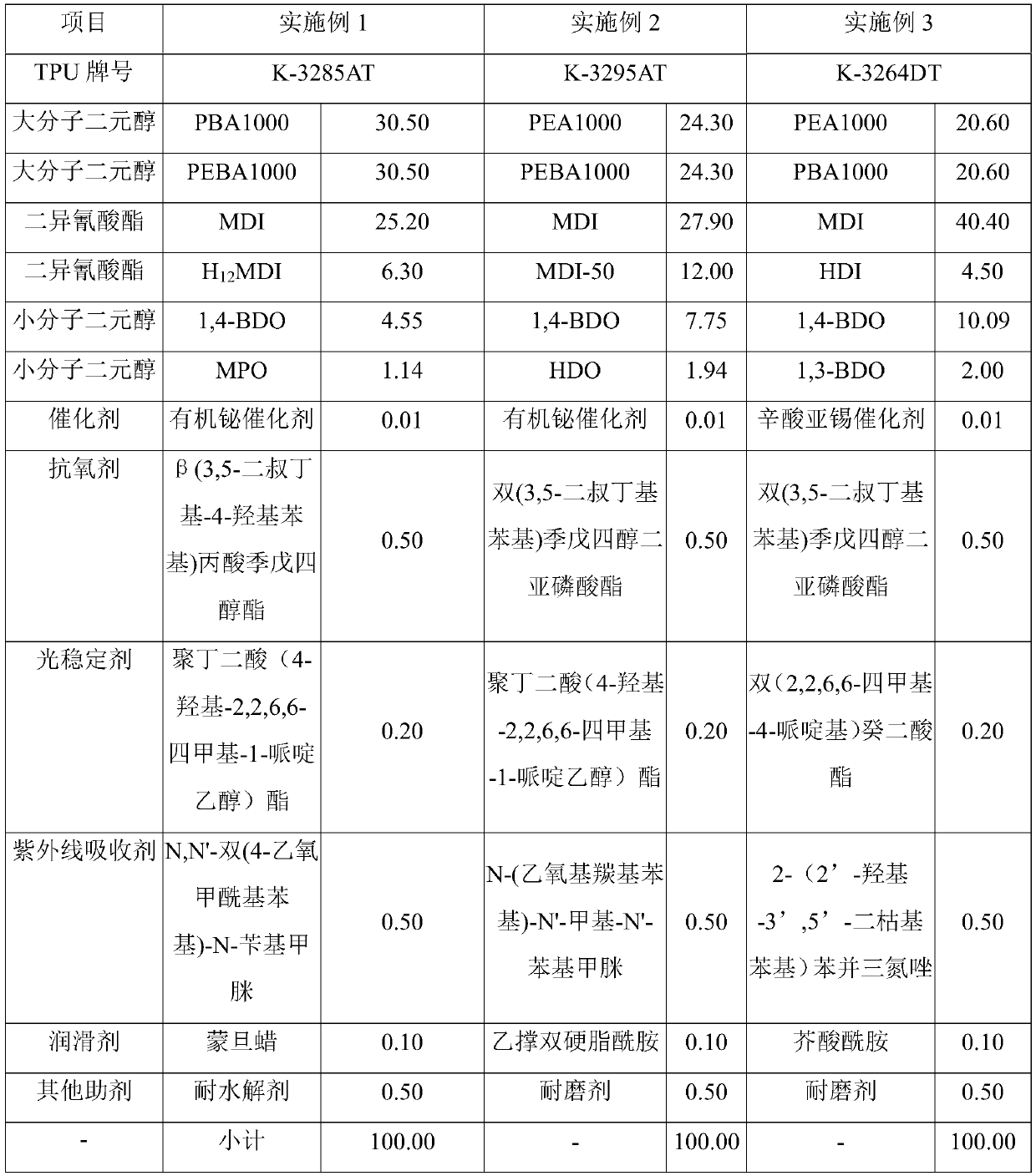

Embodiment 1

[0044] In percent by weight, 30.50% of polybutylene adipate diol (PBA1000) with a molecular weight of 1000 and 30.50% of a polybutylene adipate diol (PEBA1000) with a molecular weight of 1000 are mixed, and the storage tank The material temperature is 90±5°C; add 0.50% of antioxidant, 0.20% of light stabilizer, 0.50% of ultraviolet absorber, 0.10% of lubricant, and 0.50% of other additives into the above-mentioned macromolecular glycol storage tank, fully Stir to dissolve, this is component B.

[0045] Diisocyanate MDI 25.20% and hydrogenated MDI 6.30% are mixed as component A, and the tank of component A is kept at 60±5°C; small molecule diols BDO 4.55% and MPO 1.14% are mixed as component C, and the tank of component C is mixed The tank is kept warm at 60±5°C. The three components pass through the mass flow perfusion system respectively, set the target flow according to the mass percentage of the above three components, mix and perfuse at high speed through the mixing head ...

Embodiment 2

[0047] In weight percentage, 24.30% of polyethylene adipate diol (PEA1000) with a molecular weight of 1000 and 24.30% of a polyethylene adipate diol (PEBA1000) with a molecular weight of 1000 are mixed, and the storage tank The material temperature is 90±5°C; add 0.50% of antioxidant, 0.20% of light stabilizer, 0.50% of ultraviolet absorber, 0.10% of lubricant, and 0.50% of other additives into the above-mentioned macromolecular glycol storage tank, fully Stir to dissolve, this is component B.

[0048] Diisocyanate MDI 27.90%, MDI-50 12.00% mixed, as A component, A component tank insulation 60 ± 5 ℃; small molecular diol BDO 7.75%, HDO 1.94% mixed as C component, C component The barrel tank is kept warm at 60±5°C. The three components pass through the mass flow perfusion system respectively, set the target flow according to the mass percentage of the above three components, mix and perfuse at high speed through the mixing head into the co-rotating twin-screw reaction extruder...

Embodiment 3

[0050] In percent by weight, 20.60% of polybutylene adipate diol (PBA1000) of molecular weight 1000 and 20.60% of polyethylene adipate diol (PEA1000) of molecular weight 1000 are mixed, and the material temperature of the storage tank is 90 ±5°C; add 0.50% of antioxidant, 0.20% of light stabilizer, 0.50% of ultraviolet absorber, 0.10% of lubricant, and 0.50% of other additives into the above-mentioned macromolecular glycol storage tank, fully stir to dissolve, This is the B component.

[0051] Diisocyanate MDI 40.40%, HDI 4.50% are mixed as component A, and the tank of component A is kept at 60±5°C; small molecule diol BDO 10.09%, 1,3-BDO 2.00% are mixed as component C, C The component tank is kept warm at 60±5°C. The three components pass through the mass flow perfusion system respectively, set the target flow according to the mass percentage of the above three components, mix and perfuse at high speed through the mixing head into the co-rotating twin-screw reaction extruder...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| transparency | aaaaa | aaaaa |

| transparency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com