Preparation method of soluble, colorless, transparent and low-thermal-expansion-coefficient polyamide imide film

A polyamideimide, low thermal expansion coefficient technology, applied in the field of soluble colorless transparent low thermal expansion polyamideimide film preparation, can solve the problem of low glass transition temperature, poor temperature resistance, high heat resistance, etc. problems, to achieve excellent mechanical properties and dimensional stability, reduce intermolecular forces, and increase the effect of free volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

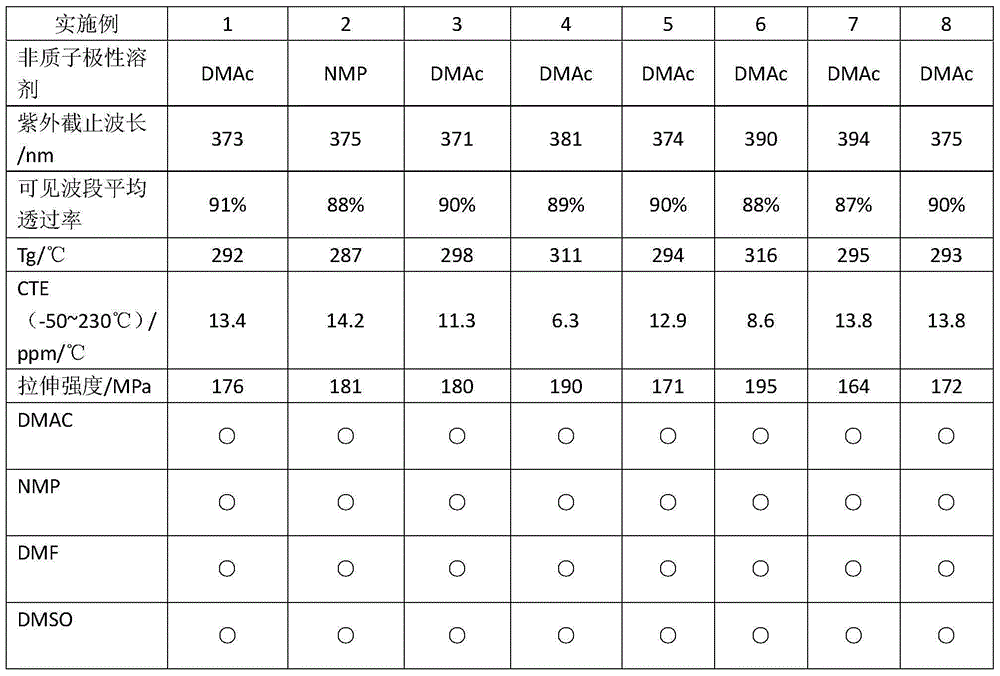

Examples

Embodiment 1

[0027] a) Weigh 2.4g of TFBZ into 7.5ml DMAc, stir and dissolve at room temperature;

[0028]b) Put it in an ice-water bath, after 15 minutes, add 1.89ml of TMSCl, 1.2ml of pyridine and 0.183g of 4-dimethylaminopyridine (DMAP), and stir at room temperature for 15 minutes;

[0029] c) After cooling down in an ice-water bath for 15 minutes, quickly add 1.578 g of TMAC, then add 7.5 ml of DMAC, stir in an ice-water bath at 0°C for 15 minutes, and then stir overnight at room temperature;

[0030] d) After overnight, if the viscosity of the glue is too high, add 7.5ml of DMAc and stir to reduce the viscosity, then add 0.765ml of acetic anhydride and 0.591ml of pyridine mixture, and stir at room temperature for 6h;

[0031] e) After cooling to room temperature, slowly pour the glue solution into 2-propanol to wash and filter for 2 to 4 times;

[0032] f) heat up to 50°C in an oven for 3 hours, and then dissolve it with 60ml of DMAc to obtain a polyamide-imide glue;

[0033] g) Coa...

Embodiment 2

[0036] The implementation method of this example is basically the same as that of Example 1, except that the aprotic polar solvent used is NMP (N-methylpyrrolidone).

[0037] a) Weigh 2.4g of TFBZ into 7.5ml of NMP, stir and dissolve at room temperature;

[0038] b) Put it in an ice-water bath, after 15 minutes, add 1.89ml of TMSCl, 1.2ml of pyridine and 0.183g of 4-dimethylaminopyridine (DMAP), and stir at room temperature for 15 minutes;

[0039] c) After cooling down in an ice-water bath for 15 minutes, quickly add 1.578 g of TMAC, then add 7.5 ml of NMP, stir in an ice-water bath at 0°C for 15 minutes, and then stir overnight at room temperature;

[0040] d) After overnight, if the viscosity of the glue is too high, add 7.5ml of NMP and stir to reduce the viscosity, then add 0.765ml of acetic anhydride and 0.591ml of pyridine mixture, and stir at room temperature for 6 hours;

[0041] e) After cooling to room temperature, slowly pour the glue solution into methanol to was...

Embodiment 3

[0046] The implementation method of this example is basically the same as that of Example 1, except that 1.2 g of TFBZ is firstly added in step a, and then the remaining 1.2 g is added before overnight stirring in step c.

[0047] a) Weigh 1.2g of TFBZ into 7.5ml DMAC, stir and dissolve at room temperature;

[0048] b) Put it in an ice-water bath, after 15 minutes, add 1.89ml of TMSCl, 1.2ml of pyridine and 0.183g of 4-dimethylaminopyridine (DMAP), and stir at room temperature for 15 minutes;

[0049] c) After cooling down in an ice-water bath for 15 minutes, quickly add 1.578g of TMAC, then add 7.5ml of DMAC, stir in an ice-water bath at 0°C for 15 minutes, then add 1.2g of TFBZ, and then stir overnight at room temperature;

[0050] d) After overnight, if the viscosity of the glue is too high, add 7.5ml of DMAC and stir to reduce the viscosity, then add 0.765ml of acetic anhydride and 0.591ml of pyridine mixture, and stir at room temperature for 6 hours;

[0051] e) After co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| dimensional stability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com