Multifunctional chromatophil copolyester fiber in high rate of retention and profile spinneret adopted

A spinneret and fiber technology, which is applied to the preparation method and the field of the spinneret used, can solve the problems of low dyeability and low water retention rate of polyester fibers, and achieve the effects of high water retention rate and soft and comfortable fabric feel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

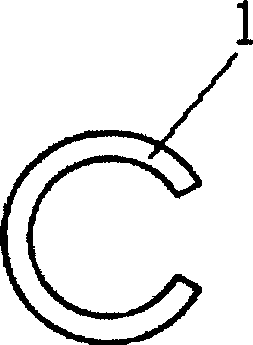

[0033] After drying the ethylene terephthalate slices, use e.g. figure 1 The special-shaped spinneret shown in the Japanese ABE Engineering Co twin-screw spinning machine and Barmag 3010 stretching machine, the control screw temperature is 290 ° C, the winding speed is 1000 m / min, the cooling air temperature is 27 ° C, and the draw ratio is 3.5 times , to produce special-shaped hollow fibers. The fineness, breaking strength and elongation at break of the obtained fibers are shown in No. 1 in Table 1. The water retention rate of the obtained fiber and the alkali weight reduction rate and water retention rate obtained after alkali reduction treatment at 95°C for 60 minutes in 10g / l or 20g / l NaOH alkali solution are shown in No. 1 in Table 2 .

Embodiment 2

[0035] After the cationic dye-dyeable copolyester chip whose SIP content of the third monomer is 3 mol% relative to PTA is dried, the special-shaped hollow fiber is obtained by the same method as in Example 1. The fineness, breaking strength and elongation at break of the obtained fibers are shown in No. 2 in Table 1. The water retention rate of the obtained fibers and the alkali weight reduction rate and water retention rate obtained after alkali reduction treatment at 95° C. for 60 minutes in 10 g / l NaOH alkali solution are shown in No. 2 in Table 2.

Embodiment 3

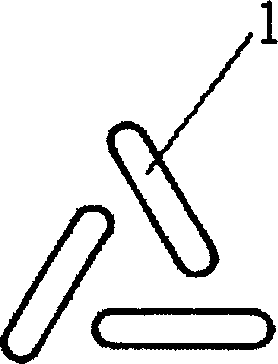

[0037] The content of the third monomer SIP relative to PTA3mol% cationic dye dyeable copolyester chips after drying, using such as figure 2 For the special-shaped spinneret shown, the same method as in Example 1 was used to prepare special-shaped hollow fibers. The fineness, breaking strength and elongation at break of the obtained fibers are shown in No. 3 in Table 1. The water retention rate of the obtained fiber and the alkali weight reduction rate and water retention rate obtained after alkali reduction treatment at 95° C. for 60 minutes in 10 g / l NaOH alkali solution are shown in No. 3 in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com