Light-masking hydrophilic fiber and preparation method thereof

A hydrophilic fiber, optical shielding technology, applied in the field of fiber manufacturing, can solve problems such as poor fabric comfort, and achieve the effects of high comfort, improved hydrophobicity, and good skin affinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

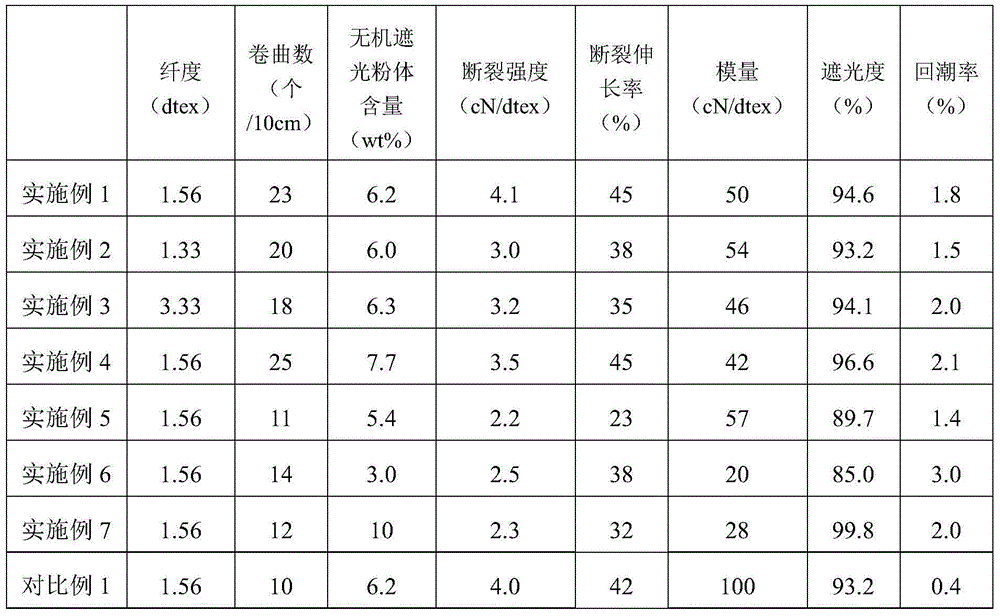

Examples

preparation example Construction

[0020] As introduced in the background technology section, the existing high optical shielding fibers have poor fabric comfort due to their hydrophobic properties. In order to solve this problem, the inventors of the present invention provide a method for preparing optically shielding hydrophilic fibers, which includes the following steps: A1, dividing the inorganic light-shielding powder into a first part and a second part, and dividing the first part of the inorganic light-shielding powder , Aromatic dibasic acid and aliphatic dibasic alcohol are configured into a mixed slurry, and after esterification, a pre-reaction melt is formed; A2, aliphatic polyamide is added to the pre-reaction melt, and after polycondensation reaction, Cooling to form a modified polyester material; A3, covering the surface of the second part of the inorganic light-shielding powder with a resin coating layer to form a composite masterbatch; A4, blending and melting the modified polyester material and ...

Embodiment 1

[0050] Prepare terephthalic acid, ethylene glycol and titanium dioxide with a particle size of 0.1 μm into a mixed slurry, wherein the molar ratio of terephthalic acid to ethylene glycol is 1:1.15, and the amount of titanium dioxide added is 1 / 2 of the mass of terephthalic acid 0.3%. Then the mixed slurry is transported to the reactor for esterification reaction, wherein the reaction temperature is 250°C, and the reaction is terminated when the esterification rate reaches 92%, to obtain a pre-reaction melt;

[0051] Add nylon 66 equivalent to 20% of the weight of terephthalic acid and 0.04% titanium-based catalyst to the above pre-reaction melt for polycondensation and copolymerization. The reaction temperature is 280°C and the reaction time is 2h. After the reaction is completed, the material is discharged and pelletized The modified polyester chip was obtained, and the intrinsic viscosity of the chip was 0.8dL / g.

[0052] Mix titanium dioxide with a particle size of 0.1 μm ...

Embodiment 2

[0055]Terephthalic acid, propylene glycol, and titanium dioxide with a particle size of 0.01 μm were formulated into a mixed slurry, wherein the molar ratio of terephthalic acid to propylene glycol was 1:1.8, and the amount of titanium dioxide added was 3% of the mass of terephthalic acid. Then the mixed slurry is transported to the reactor for esterification reaction, wherein the reaction temperature is 250°C, and the reaction is terminated when the esterification rate reaches 96%, to obtain a pre-reaction melt;

[0056] Add nylon 6 equivalent to 5% of the weight of terephthalic acid and 0.1% titanium-based catalyst to the above pre-reaction melt for polycondensation and copolymerization. The reaction temperature is 260°C and the reaction time is 3h. After the reaction is completed, the material is discharged and pelletized Modified polyester chips were obtained, and the intrinsic viscosity of the chips was 1.2 dL / g.

[0057] Mix titanium dioxide with a particle size of 0.01 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com