Novel crude oil demulsifier and preparation method thereof

A technology of crude oil demulsifier and demulsifier, which is applied in the direction of chemical dehydration/demulsification to achieve good demulsification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

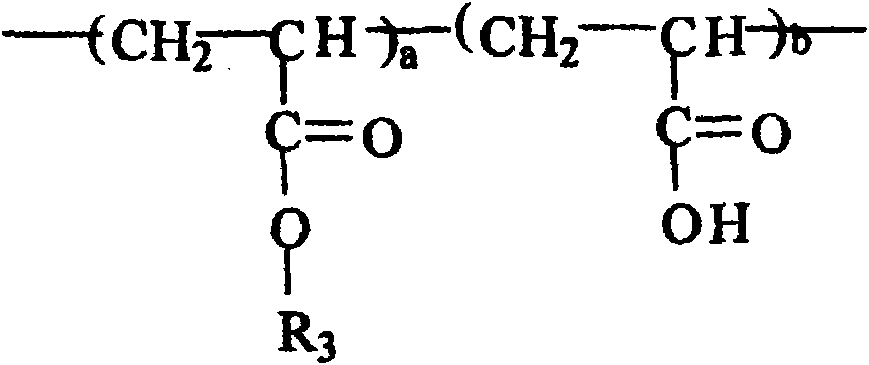

Method used

Image

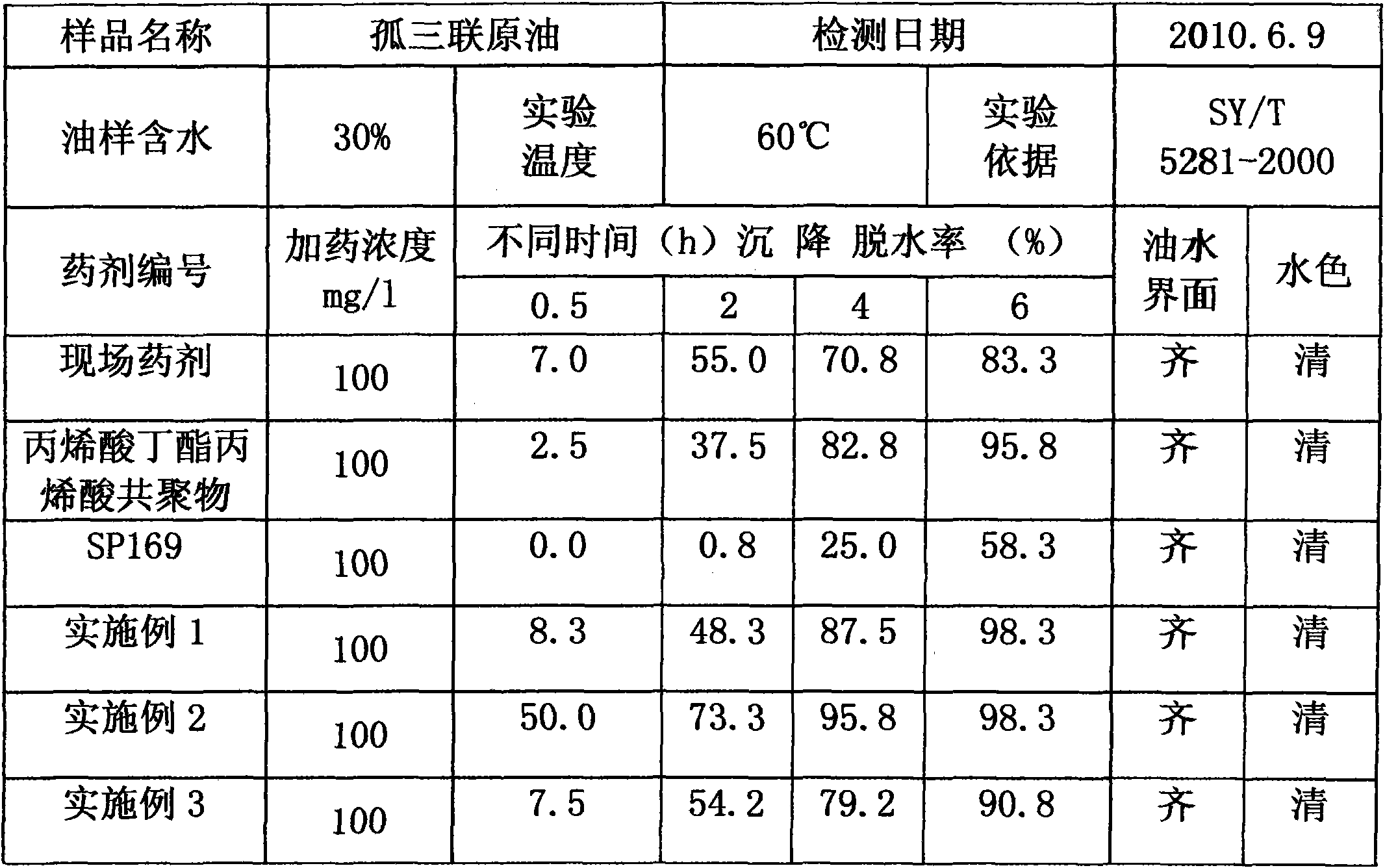

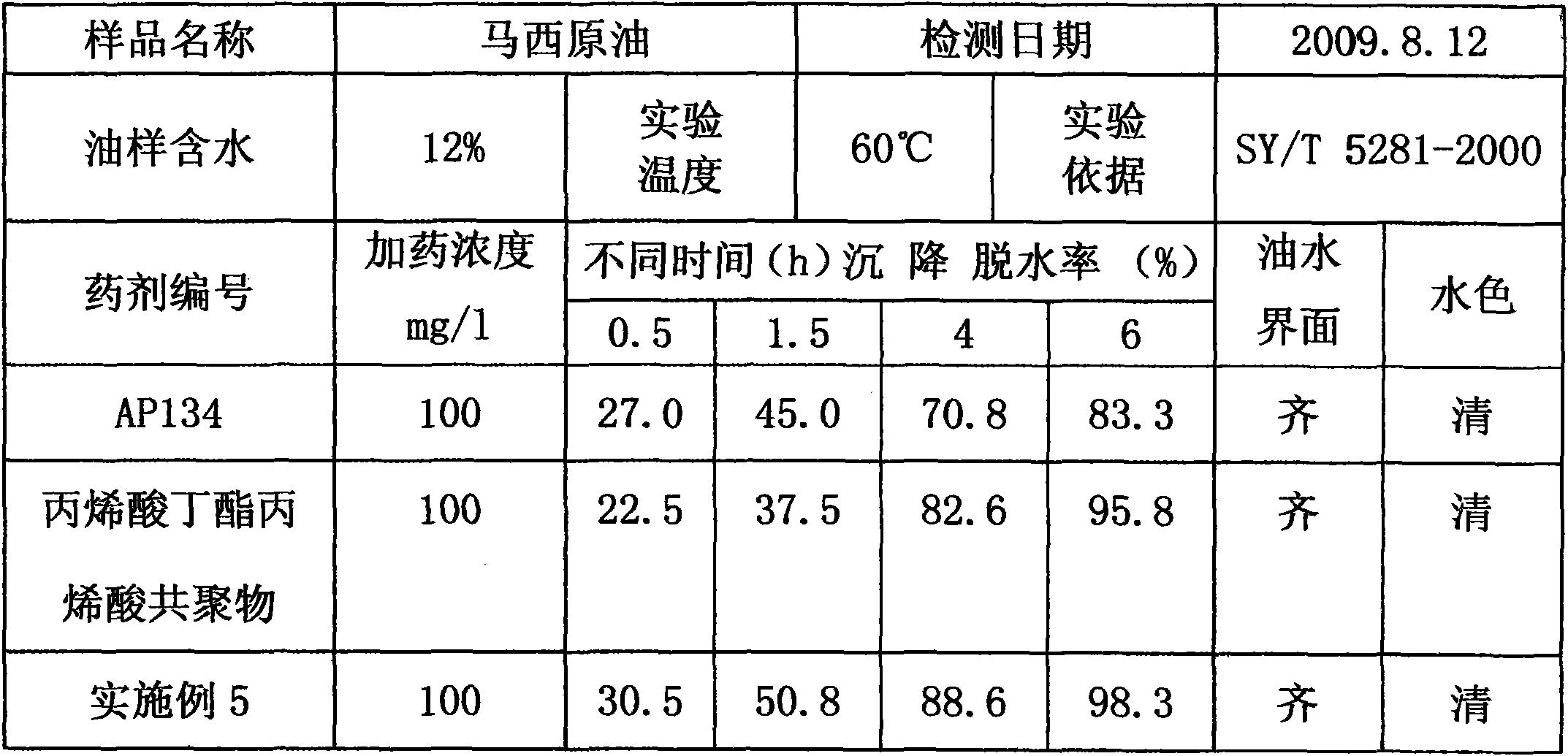

Examples

no. 1 example

[0048] A four-neck flask equipped with a stirrer and a condensing reflux device was placed in a water bath, and the temperature of the water bath was raised to 60° C., 41.4 grams of butyl acrylate and 55 grams of xylene were added, stirred evenly, replaced with nitrogen and continuously fed with nitrogen. Add 0.25 g of azobisisobutyronitrile as an initiator, stir evenly and add 1.1 g of acrylic acid, start to add acrylic acid dropwise after 15 minutes, add 2.2 g dropwise within 4 hours, and continue to react for 4 hours after the dropwise addition is completed. Thereafter, add 0.3 gram of hydroquinone as a terminator, then react at a constant temperature for 0.5 hours, then lower the temperature to obtain a white solution, according to the People's Republic of China national standard GB / T 1668-95 plasticizer acid value and the mensuration of acidity, use acid Alkali titration was used to measure the carboxyl content, and it was found that it contained 7.40% of acrylic acid unit...

no. 2 example

[0050] A four-neck flask equipped with a stirrer and a condensing reflux device was placed in a water bath, and the temperature of the water bath was raised to 60° C., 41.4 grams of butyl acrylate and 55 grams of xylene were added, stirred evenly, replaced with nitrogen and continuously fed with nitrogen. Add 0.25 g of azobisisobutyronitrile as an initiator, stir evenly, add 1.1 g of acrylic acid, add 1.1 g of acrylic acid every 1.5 hours, add acrylic acid three times, the total amount is 3.3 g, and continue the reaction at 60° C. for 4 hours. Thereafter, add 0.3 gram of hydroquinone as a terminator, then react at a constant temperature for 0.5 hours, then lower the temperature to obtain a white solution, according to the People's Republic of China national standard GB / T 1668-95 plasticizer acid value and the mensuration of acidity, use acid Alkali titration was used to measure the carboxyl group content, and it was found that it contained 7.38% of acrylic acid units, the numbe...

no. 3 example

[0052] The preparation method is the same as in Example 2, except that the solvent is methyl ethyl ketone, the amount of acrylic acid added in batches is 4.8 grams, and the total amount of acrylic acid is 14.4 grams. According to the national standard GB / T 1668-95 of the People's Republic of China for the determination of the acid value and acidity of plasticizers, the carboxyl content of the product was determined by acid-base titration, and it was found that it contained 25.85% of acrylic acid units, and the number average molecular weight was 72,000. The molecular weight distribution Mw / Mn was 2.95.

[0053] The preparation method of novel crude oil demulsifier of the present invention comprises the following specific steps:

[0054] Step 1, add butyl acrylate acrylic acid copolymer, polyether type demulsifier and solvent into the reactor, after the butyl acrylate acrylic acid copolymer and polyether type demulsifier are completely dissolved in the solvent, add acidic catal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com