Water-based electrode binding agent and preparation method thereof

A binder and electrode technology, used in adhesives, battery electrodes, binder types, etc., can solve the problem of not many water-based binders, and achieve fast polymerization reaction speed, high monomer conversion rate, and narrow molecular weight distribution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

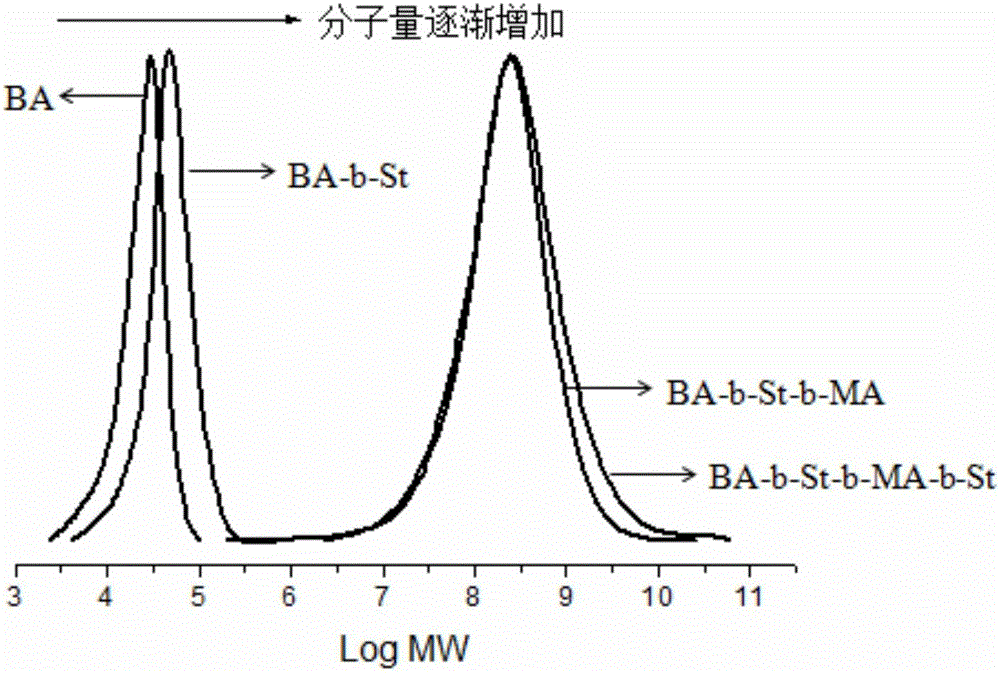

[0025] The preparation method of water-based electrode binder butyl acrylate / styrene / methyl acrylate block copolymer latex of the present invention comprises the following steps:

[0026] (1) stirring and dissolving 0.2-0.8 parts by weight of amphiphilic macromolecular reversible addition fragmentation chain transfer reagent in 30-50 parts by weight of water to form an aqueous phase, then pouring 10 parts by weight of BA into the reactor and stirring and mixing; Raise the reaction temperature to 60-80°C, keep stirring, pass nitrogen to remove oxygen for 5-30 minutes, add 0.005-0.02 parts by weight of a water-soluble initiator, and polymerize for 0.5-2 hours to obtain R-AA n1 -b-St n2-b-BA n3 -X block copolymer, R-AA n1 -b-St n2 -b-BA n3 -X block copolymers are stably dispersed in water in the form of particles to form latex;

[0027] (2) Add 1.25-5 parts by weight of St monomer to the latex obtained in step 1, and continue to react for 0.5-1 hour to obtain R-AA n1 -b-St ...

Embodiment 1

[0048] (1) 0.2 parts by weight of amphiphilic macromolecular reversible addition fragmentation chain transfer reagent is stirred and dissolved in 30 parts by weight of water to form an aqueous phase, then 10 parts by weight of BA is poured into the reactor and stirred and mixed; the reaction temperature is raised To 70°C, keep stirring, pass nitrogen to remove oxygen for 20 minutes, add 0.005 parts by weight of water-soluble initiator, and polymerize for 2 hours to obtain R-AA n1 -b-St n2 -b-BA n3 -X block copolymer, R-AA n1 -b-St n2 -b-BA n3 -X block copolymers are stably dispersed in water in the form of particles to form latex;

[0049] (2) Add 5 parts by weight of St monomer to the latex obtained in step 1, and continue to react for 1 hour to obtain R-AA n1 -b-St n2 -b-BA n3 -b-St n4 -X block copolymer, R-AA n1 -b-St n2 -b-BA n3 -b-St n4 -X block copolymers are stably dispersed in water in the form of particles to form latex;

[0050] (3) Add 30 parts by weigh...

Embodiment 2

[0056] (1) 0.8 parts by weight of amphiphilic macromolecular reversible addition fragmentation chain transfer reagent is stirred and dissolved in 50 parts by weight of water to form an aqueous phase, then 10 parts by weight of BA is poured into the reactor and stirred and mixed; the reaction temperature is raised To 70°C, keep stirring, pass nitrogen to remove oxygen for 20 minutes, add 0.02 parts by weight of water-soluble initiator, and polymerize for 0.5 hours to obtain R-AA n1 -b-St n2 -b-BA n3 -X block copolymer, R-AA n1 -b-St n2 -b-BA n3 -X block copolymers are stably dispersed in water in the form of particles to form latex;

[0057] (2) Add 1.25 parts by weight of St monomer to the latex obtained in step 1, and continue to react for 0.5 hours to obtain R-AA n1 -b-St n2 -b-BA n3 -b-St n4 -X block copolymer, R-AA n1 -b-St n2 -b-BAn3 -b-St n4 -X block copolymers are stably dispersed in water in the form of particles to form latex;

[0058] (3) Add 12.5 parts b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com