Durable, waterproof, oil-proof, antistatic and antibacterial functional coating adhesive and preparation method

An antistatic, functional technology, applied in textiles, papermaking, fiber treatment, etc., can solve the problems of single-functional coating glue, poor washing resistance, durable waterproof, oil-proof, antistatic, and antibacterial coating glue. Issues such as disclosure of technology to achieve the effects of good film fastness, good washing resistance and good oleophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

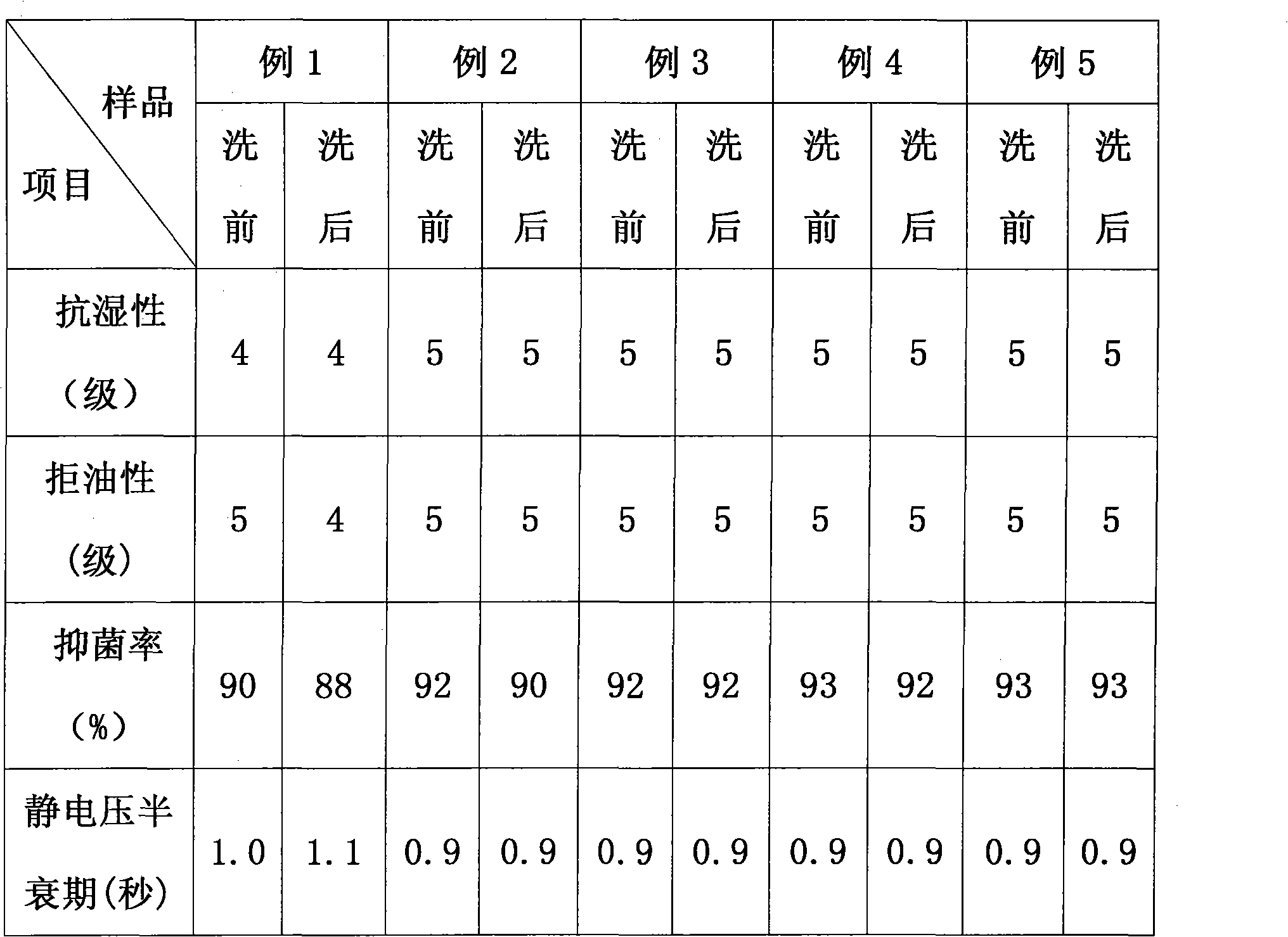

Examples

Embodiment 1

[0025] (1) Emulsified mixed monomer: add 25 grams of methyl acrylate, 80 grams of n-butyl acrylate, 3.0 grams of glycidyl methacrylate, 1.0 grams of allyl methacrylate, 2, 2, methacrylic acid in a stainless steel kettle 2-trifluoroethyl ester 10, acryloyloxyethyltrimethylammonium chloride 20, fatty alcohol polyoxyethylene ether XL90 6.5 grams, deionized water 220 grams, stirred and emulsified for 30 minutes to prepare an emulsion;

[0026] (2) Initiate polymerization reaction: take 20% of the total amount of the emulsion, that is, 73.1 grams, add it to the reactor, heat up to 72-75°C, add initiator 2, 2-azobis(2-methylpropionamidine) salt A mixture of 0.2 g of acid salt and 10 g of water is initiated, and then 292.4 g of the remaining emulsion is added dropwise at 72-75°C, and at the same time, the initiator 2, 2-azobis(2-methylpropionamidine) salt is added dropwise A mixture of 0.9 g of acid salt and 30 g of water was added dropwise in 3.0 hours, then kept at 82-85°C for 1.5 ...

Embodiment 2

[0029] The weight ratio of raw materials is: 26 grams of methyl acrylate, 82 grams of n-butyl acrylate, 4.0 grams of glycidyl methacrylate, 1.2 grams of allyl methacrylate, 12 grams of 2,2,2-trifluoroethyl methacrylate , acryloyloxyethyltrimethylammonium chloride 22, fatty alcohol polyoxyethylene ether XL90 is 6.8 grams, cetyltrimethylammonium chloride 7.5 grams, 2, 2- azobis (2-methyl Propionamidine) hydrochloride 1.2 grams, deionized water 245 grams, associative polyurethane leveling rheology agent WT-203 is 3.7 grams; The technological process of production is with embodiment 1.

Embodiment 3

[0031] The weight ratio of raw materials is: 27 grams of methyl acrylate, 85 grams of n-butyl acrylate, 5.0 grams of glycidyl methacrylate, 1.4 grams of allyl methacrylate, 13 grams of 2,2,2-trifluoroethyl methacrylate , acryloyloxyethyltrimethylammonium chloride 24, fatty alcohol polyoxyethylene ether XL90 is 7.1 grams, cetyltrimethylammonium chloride 8.0 grams, 2, 2- azobis (2-methyl 1.5 grams of propionamidine) hydrochloride, 260 grams of deionized water, and 3.9 grams of associative polyurethane leveling rheological agent WT-203, the production process is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com