Nano-silver-containing adhesive and using method of adhesive in technical wood

A nano-silver and adhesive technology, applied in the direction of adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problems of use, can not be used as adhesives, etc., achieve good stability and dispersibility, resist the Invasion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

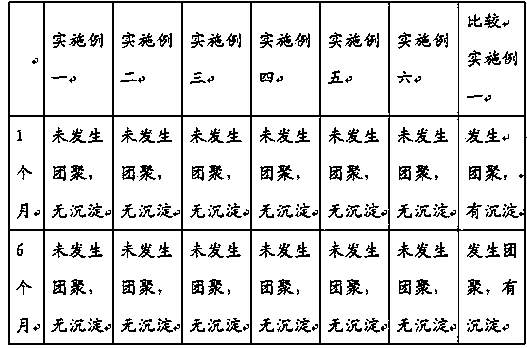

Examples

Embodiment 1

[0048] Preparation of nano silver:

[0049] Add sodium dodecylsulfonate solution and hydrazine hydrate solution to silver nitrate aqueous solution to obtain a mixed solution, the molar ratio of sodium dodecylsulfonate to silver nitrate is 2:1; the hydrazine hydrate and nitric acid The molar ratio of silver is 2:5;

[0050] Heat the mixture to 45°C, add dicyclohexane-18-crown-6 and sodium borohydride to the mixture while stirring, heat to 70°C, and keep stirring for 5 minutes; dicyclohexane-18-crown The molar ratio of -6 to silver nitrate is 1:1; the molar ratio of sodium borohydride to silver nitrate is 0.5:1, and the pH value is controlled to be 8 to obtain nano silver.

[0051]

[0052] Preparation of adhesive containing nano silver:

[0053] Apply nano-silver evenly in the environment-friendly glue solution, and use flour as an additive for glue; the concentration of nano-silver in the adhesive is 75ppm; the mass content of flour in the solution is 18%;

[0054] Environme...

Embodiment 2

[0065] Preparation of nano silver:

[0066] Add sodium dodecylsulfonate solution and hydrazine hydrate solution to silver nitrate aqueous solution to obtain a mixed solution, the molar ratio of sodium dodecylsulfonate to silver nitrate is 3:1; the hydrazine hydrate and nitric acid The molar ratio of silver is 3:5;

[0067] Heat the mixture to 55°C, add dicyclohexane-18-crown-6 and potassium borohydride to the mixture while stirring, heat to 85°C, and keep stirring for 8 minutes; dicyclohexane-18-crown The molar ratio of -6 to silver nitrate is 1-2:1; the molar ratio of potassium borohydride to silver nitrate is 0.5-1:1, and the pH value is controlled to be 8-9 to obtain nano silver.

[0068]

[0069] Preparation of adhesive containing nano silver:

[0070] Apply nano-silver evenly in the environment-friendly glue solution, and use flour as the glue additive; the concentration of nano-silver in the adhesive is 150ppm; the mass content of flour in the solution is 45%;

[007...

Embodiment 3

[0081] Preparation of nano silver:

[0082] Add sodium dodecylsulfonate solution and hydrazine hydrate solution to silver nitrate aqueous solution to obtain a mixed solution, the molar ratio of sodium dodecylsulfonate to silver nitrate is 5:2; the hydrazine hydrate and nitric acid The molar ratio of silver is 1:2;

[0083] Heat the mixture to 50°C, add dicyclohexane-18-crown-6 and sodium metaphosphate to the mixture while stirring, heat to 75°C, and keep stirring for 6 minutes; dicyclohexane-18-crown The molar ratio of -6 to silver nitrate is 1.5:1; the molar ratio of sodium metaphosphate to silver nitrate is 0.8:1, and the pH value is controlled to be 8.5 to obtain nano silver.

[0084]

[0085] Preparation of adhesive containing nano silver:

[0086] Apply nano-silver evenly in the environment-friendly glue solution, and use flour as the glue additive; the concentration of nano-silver in the adhesive is 100ppm; the mass content of flour in the solution is 25%;

[0087] E...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com