Micro-emulsion method for preparing nano-sulfur particles

A technology of nano-sulfur and micro-emulsion, which is applied in the field of chemistry and chemical engineering, can solve problems such as complex processes, and achieve the effects of uniform particle size distribution, adjustable particle size distribution, and simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

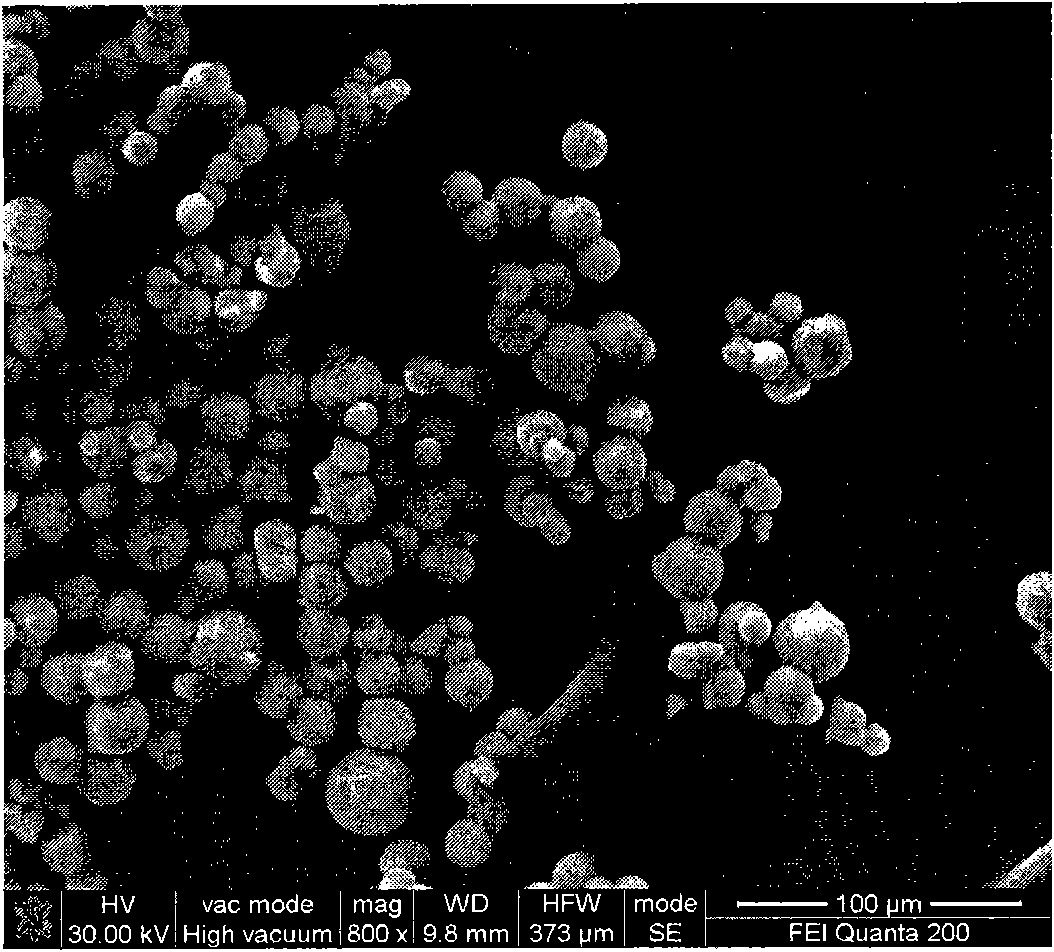

[0037] After mixing 8g span80-tween80 composite surfactant (HLB: 5.5), 1ml n-butanol and 45ml n-octane for 15 minutes, add 3ml Na 2 S x(0.5mol / L) solution and stirred to obtain clear microemulsion A in 15 minutes. Prepare clear microemulsion B containing 3ml HCl (1mol / L) solution in the same way (that is, after mixing 8g span80-tween80 composite surfactant (HLB: 5.5), 1ml n-butanol and 45ml n-octane for 15 minutes, add 3ml HCl (1mol / L) solution and stirred for 15 minutes to obtain a clear microemulsion B). Then microemulsion A and microemulsion B were mixed and stirred for 30 minutes, then aged for 12 hours, then a certain amount of acetone was added and stirred to obtain a precipitate, and the precipitate was alternately washed with deionized water and acetone under suction filtration conditions to remove the oil phase and surface activity agent, and then dried under vacuum at 50°C for 12 hours to obtain the product sulfur particles. The particle size range of gained produ...

Embodiment 2

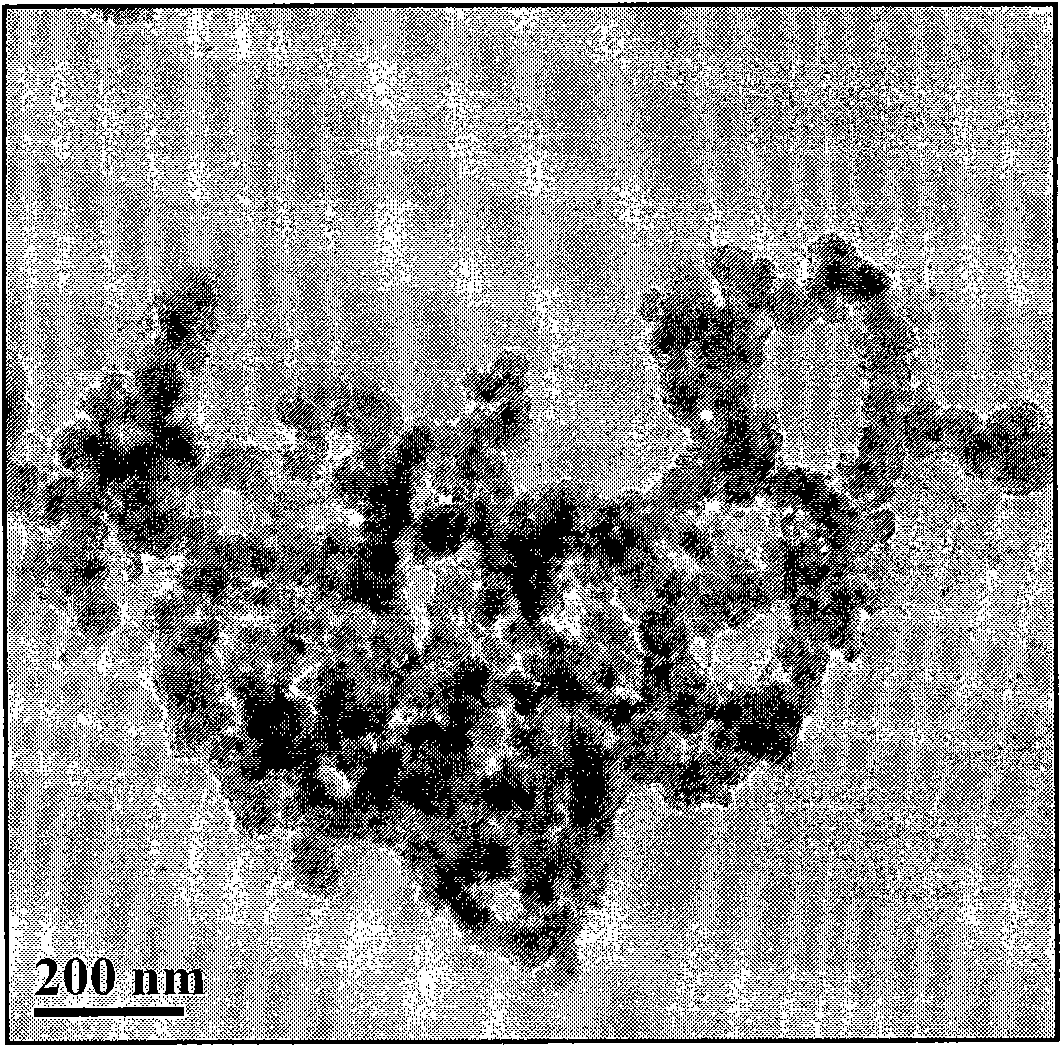

[0039] After mixing 4g tween80, 0.5ml n-butanol and 20ml n-octane for 15 minutes, add 1ml Na 2 S x (0.5mol / L) solution and stirred for 15 minutes to obtain clear microemulsion A; prepare clear microemulsion B containing 1ml HCl (1mol / L) solution with the same method. Then the product sulfur particles were obtained according to the method of Example 1. The particle size range of the obtained product sulfur is shown in Table 1. The detection by transmission electron microscope and XRD proves that the particle size distribution of the obtained nano-sulfur is uniform, there is no agglomeration phenomenon, and it is an orthorhombic crystal system without impurity phases.

Embodiment 3

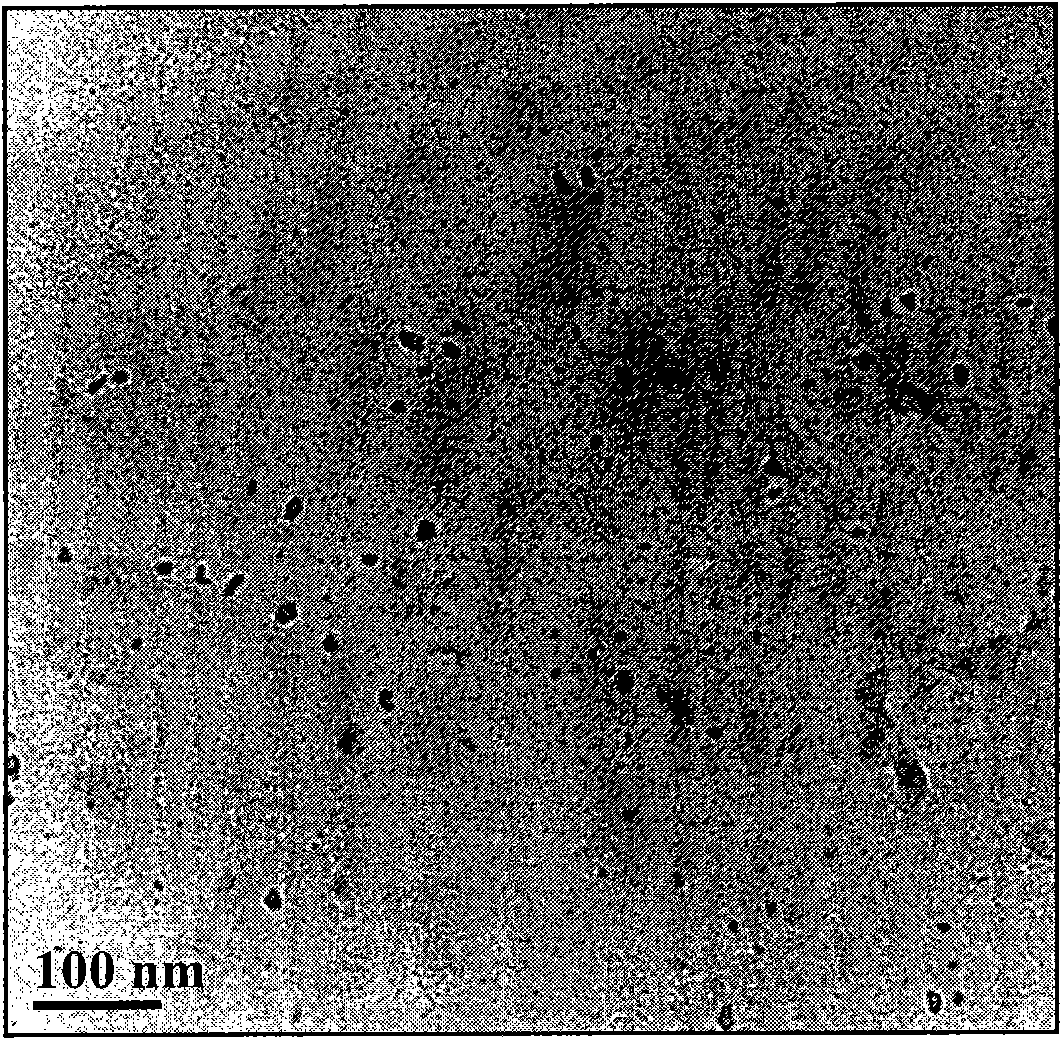

[0041] Stir 2g of cetyltrimethylammonium bromide (CTAB), 2ml of n-butanol and 30ml of n-octane for 15 minutes to make them evenly mixed, then add 2ml of Na 2 S x (0.5mol / L) solution and stirred for 30 minutes to clear microemulsion A; the same method was prepared to obtain clear microemulsion B containing 2ml HCl (1mol / L) solution. Then obtain sulfur particles according to the method of Example 1. The particle size range of gained product sulfur is shown in Table 1, and its transmission electron microscope figure is as follows image 3 shown. The detection by transmission electron microscope and XRD proves that the particle size distribution of the obtained nano-sulfur is uniform, there is no agglomeration phenomenon, and it is an orthorhombic crystal system without impurity phases.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com